UYANG BELTING Tobacco Nitrile Rubber Belt is specially developed for the tobacco processing industry, with strict cleanliness, anti-static, and non-contaminating requirements of tobacco handling environments, and exceptional dimensional stability, durability, and precise tracking — even under long-term continuous operation. The surface pattern and rubber formula can be tailored to prevent tobacco product adhesion and reduce dust accumulation.

UYANG BELTING Tobacco Nitrile Rubber Belt is specially developed for the tobacco processing industry, with strict cleanliness, anti-static, and non-contaminating requirements of tobacco handling environments, and exceptional dimensional stability, durability, and precise tracking — even under long-term continuous operation. The surface pattern and rubber formula can be tailored to prevent tobacco product adhesion and reduce dust accumulation.

Tobacco Leaf Handling & Processing

Cigarette Production & Packaging Lines

Cut Tobacco Conveying

Drying, Blending, and Storage Lines

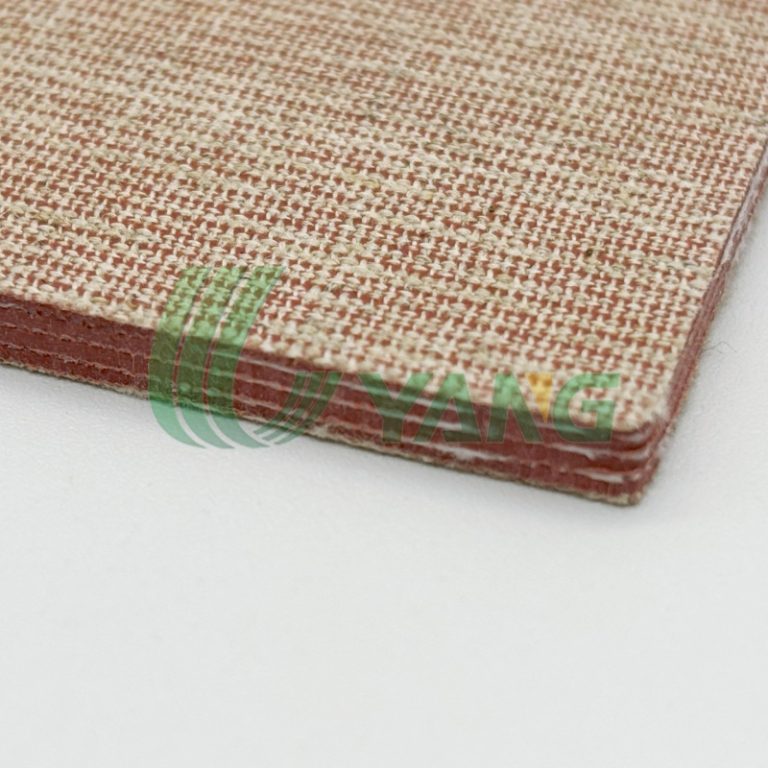

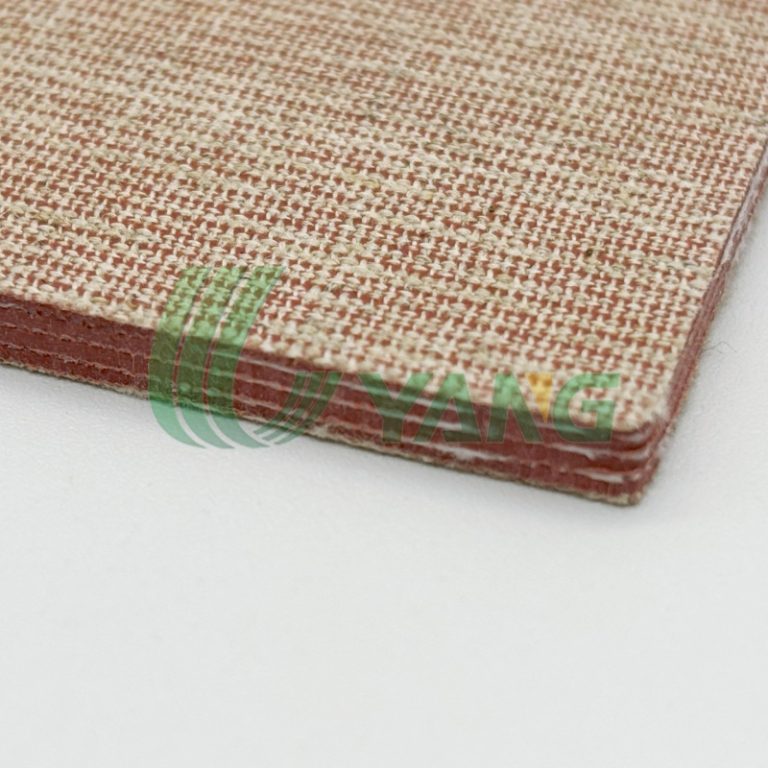

| Item | Details |

|---|---|

| Material | Natural Rubber |

| Structure | 5 Ply Fabric / 4 Rubber Layers |

| Thickness | 4.0 mm |

| Surface Texture | Fabric |

| Features | Anti-static, wear-resistant, low noise, non-toxic, |

| Industry Focus | Mainly used in Primary processing of tobacco leaves; |

✅ Non-Toxic

✅ 5 Ply Fabric Reinforcement

Provides high tensile strength and minimal elongation, ideal for continuous and high-speed conveying systems.

✅ 4-Layer Rubber Coating

Ensures excellent surface grip and wear resistance, while maintaining flexibility over pulleys and curves.

✅ Anti-Dust & Clean Surface Design

Reduces tobacco dust retention, ensuring clean material transport and easy maintenance.

✅ Customizable Surface Texture

Can be finished with smooth, fine fabric, or anti-slip embossing to suit specific stages of tobacco processing.

✅ Stable Tracking & Long Service Life

Engineered for low noise, minimal slippage, and consistent performance, even in humid or temperature-variable environments.

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1. Confirmed Specification: thickness,color, plies,characteristic, and industry;

2. Samples sending: we send samples for you check.or you send us samples if customized belt.

3. Confirm Order: Signing sales contract after samples confirmed.

4. Deposit: 30% deposit before mass production.

5. Production arranged : we will process the production.

6. Remaining payment: after inspection, balance before shipment.

7. Shipping: we will ship the goods to destination port.

8. Confirm bill of loading/commercial invoice/packing list/certificate of origin;