UYANG BELTING Tracking guides are essential tracking components that ensure precise belt alignment, preventing deviation while enhancing drive efficiency and operational stability.Available in PU/PVC materials with smooth/toothed designs, food-grade options included;

UYANG BELTING Tracking guides are essential tracking components that ensure precise belt alignment, preventing deviation while enhancing drive efficiency and operational stability.Available in PU/PVC materials with smooth/toothed designs, food-grade options included;

Key Benefits:

Typical Industrial Applications:

Conveyor Performance with V-Guide Integration

To achieve superior belt tracking and operational efficiency, conveyor systems can be enhanced with precision V-guides. These guiding elements maintain exact longitudinal alignment while improving drive system responsiveness.

Comprehensive V-Guide Selection:

Color-Coded Material Specifications:

• PVC Range: White, green, blue, black

• PU Range: White (natural), transparent, green, blue

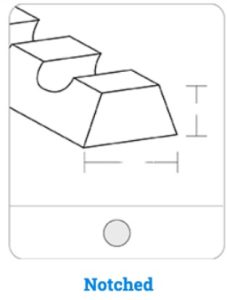

Compared to Solid guides, notched versions reduce energy consumption by up to 15% in applications requiring frequent start-stop, reverse operation, or wet conditions—making them the optimal choice for smart factory upgrades.

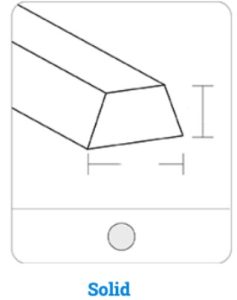

| Solid Tracking V-Guide |  |

|

|

|

| Notched Tracking V-Guide |  |

|

|

|

| Technical Data of PVC Solid V-guide | ||||||||

| Type | Material | color | Base (width) | Height | Top (width) | Surface | Min pulley (inch) | Temperature (℃) |

| K6 | PVC | Blue/green/ white/black |

6mm | 4mm | 4mm | Smooth(Solid) | 1.5inch | -15/80 |

| K8 | PVC | Blue/green/ white/black |

8mm | 5mm | 4mm | Smooth(Solid) | 2.0inch | -15/80 |

| K10 | PVC | Blue/green/ white/black |

10mm | 6mm | 6mm | Smooth(Solid) | 2.5inch | -15/80 |

| K13 | PVC | Blue/green/white/black | 13mm | 8mm | 7mm | Smooth(Solid) | 3.5inch | -15/80 |

| K17 | PVC | Blue/green/white/black | 17mm | 11mm | 10mm | Smooth(Solid) | 4.5inch | -15/80 |

| K22 | PVC | Blue/green/white/black | 22mm | 13mm | 11mm | Smooth(Solid) | 7.0inch | -15/80 |

| Technical Data of PVC notched V-guide | ||||||||

| Type | Material | color | Base (width) | Height | Top (width) | Surface | Min pulley (inch) | Temperature (℃) |

| K6 | PVC | Blue/green/ white/black |

6mm | 4mm | 4mm | Notched | 1.0inch | -15/80 |

| K8 | PVC | Blue/green/ white/black |

8mm | 5mm | 4mm | Notched | 1.5inch | -15/80 |

| K10 | PVC | Blue/green/ white/black |

10mm | 6mm | 6mm | Notched | 2.0inch | -15/80 |

| K13 | PVC | Blue/green/white/black | 13mm | 8mm | 7mm | Notched | 3.0inch | -15/80 |

| K17 | PVC | Blue/green/white/black | 17mm | 11mm | 10mm | Notched | 4.0inch | -15/80 |

| K22 | PVC | Blue/green/white/black | 22mm | 13mm | 11mm | Notched | 6.5inch | -15/80 |

| Technical Data of TPU Solid V-guide | ||||||||

| Type | Material | color | Base (width) | Height | Top (width) | Surface | Min pulley (inch) | Temperature (℃) |

| K6 | PU | Blue/green/ white/black |

6mm | 4mm | 4mm | Smooth( Solid) | 1.5inch | -15/80 |

| K8 | PU | Blue/green/ white/black |

8mm | 5mm | 4mm | Smooth( Solid) | 2.0inch | -15/80 |

| K10 | PU | Blue/green/ white/black |

10mm | 6mm | 6mm | Smooth( Solid) | 2.5inch | -15/80 |

| K13 | PU | Blue/green/white/black | 13mm | 8mm | 7mm | Smooth( Solid) | 3.5inch | -15/80 |

| K17 | PU | Blue/green/white/black | 17mm | 11mm | 10mm | Smooth( Solid) | 4.5inch | -15/80 |

| Technical Data of TPU notched V-guide | ||||||||

| Type | Material | color | Base (width) | Height | Top (width) | Surface | Min pulley (inch) | Temperature (℃) |

| K6 | PU | Blue/green/ white/black |

6mm | 4mm | 4mm | Notched | 1.0inch | -15/80 |

| K8 | PU | Blue/green/ white/black |

8mm | 5mm | 4mm | Notched | 1.5inch | -15/80 |

| K10 | PU | Blue/green/ white/black |

10mm | 6mm | 6mm | Notched | 2.0inch | -15/80 |

| K13 | PU | Blue/green/white/black | 13mm | 8mm | 7mm | Notched | 3.0inch | -15/80 |

| K17 | PU | Blue/green/white/black | 17mm | 11mm | 10mm | Notched | 4.0inch | -15/80 |

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1. Confirmed Specification: thickness,color, plies,characteristic, and industry;

2. Samples sending: we send samples for you check.or you send us samples if customized belt.

3. Confirm Order: Signing sales contract after samples confirmed.

4. Deposit: 30% deposit before mass production.

5. Production arranged : we will process the production.

6. Remaining payment: after inspection, balance before shipment.

7. Shipping: we will ship the goods to destination port.

8. Confirm bill of loading/commercial invoice/packing list/certificate of origin;