Introduction

Walk into any meat or dairy processing facility and you’ll notice one thing almost immediately: cleaning never stops. Water hoses, foaming agents, and the smell of sanitizers are as much part of the production floor as the machinery itself. For good reason—contamination can ruin tons of product in a matter of hours. At the heart of this battle against bacteria lies something that often doesn’t get enough attention: the conveyor belt.

While most people think of conveyor belts as just a moving surface, the material choice behind it can be the difference between smooth daily operations and endless downtime for cleaning. Among the options—PVC, PU, modular plastic—polyether-based conveyor belts have carved out a strong niche in meat and dairy production lines.

This article looks at why polyether conveyor belts are such a reliable ally when hygiene is non-negotiable.

Key Hygiene Features of Polyether Conveyor Belts

Seamless, Homogeneous Surface

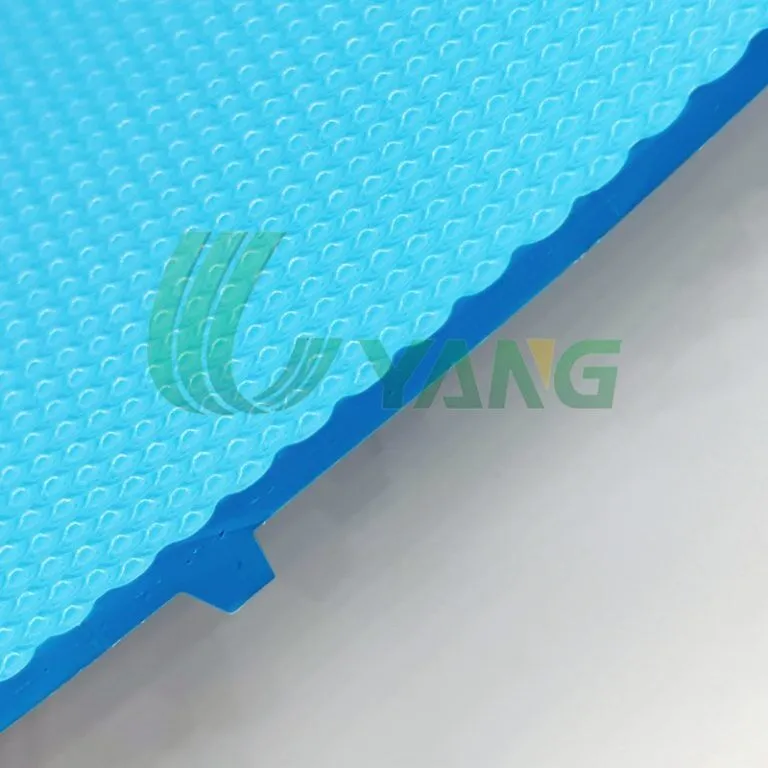

Polyether conveyor belts are typically manufactured with a smooth, fabric-free structure. No fibers. No gaps. No hidden seams. That means when raw meat juices or dairy byproducts drip onto the belt, there’s nowhere for bacteria to hide.

One of our clients in Eastern Europe once joked that “the belt is easier to clean than my kitchen counter.” It sounds like an exaggeration, but when you cut cleaning time from 45 minutes per shift to under 20, the math is convincing. Less downtime means more production, and in industries where margins are tight, every minute counts.

Chemical and Hydrolysis Resistance

Meat and dairy plants don’t just wash with water—they go heavy on caustic chemicals, chlorine solutions, and sometimes even steam. Polyether belts are resistant to hydrolysis, so they don’t degrade when exposed to hot, humid environments or aggressive cleaning routines.

Compare that with PVC belts, which can stiffen, crack, or absorb moisture after repeated washdowns. Nobody wants to explain to a quality inspector why fibers are peeling off into the product.

Food-Safe and Smooth by Design

Polyether belts comply with FDA and EU food contact regulations. They’re non-toxic and non-porous. The smooth surface helps food slide across without sticking, which doesn’t just improve hygiene—it also makes handling soft cheese blocks or raw poultry fillets less messy.

Operational and Cleaning Advantages

Shorter Cleaning Cycles, Lower Costs

One hygiene manager we spoke to in a Spanish dairy plant estimated that switching to polyether belts reduced their annual water usage for cleaning by 15%. That’s not only cost savings on water and detergents—it’s also less wastewater treatment downstream.

For operators, there’s another hidden benefit: cleaning teams prefer working with belts that don’t fight back. A surface that rinses clean in a few passes is easier on staff morale than one that needs endless scrubbing.

Durability in Harsh Environments

Polyether belts withstand temperature swings—from chilled cutting rooms at 2°C to hot-water washdowns at 80°C. In meat plants where the belt might transport both frozen beef and then undergo a steam clean, that thermal stability is a big deal. UYANG BELTING, with its 15 advanced production lines and FDA/EU certified belts, designs polyether belts to keep running smoothly in exactly these conditions.

Reduced Risk of Cross-Contamination

When switching between product batches—say, from pork to poultry or from butter to yogurt—the belt surface can be sanitized quickly and reliably. That reduces cross-contamination risks and keeps the line compliant with HACCP audits.

Compliance, Safety Standards & Certifications

Food safety regulations aren’t optional. Polyether conveyor belts typically meet:

FDA (U.S.) and EU 10/2011 food contact standards

HACCP and GMP design guidelines for hygienic equipment

USDA requirements for meat and dairy handling

UYANG BELTING highlights compliance not as a “tick-the-box” feature but as a core part of their product design. For global clients in 50+ countries, being able to show auditors the belt’s certification documents makes life a lot easier.

In recent years, there’s been growing interest in specialized hygienic belts, such as antimicrobial or dual-detectable versions (where the belt can be picked up by both metal and X-ray detectors). These niche solutions might not be needed in every plant, but they show how the industry keeps pushing hygiene one step further.

Choosing the Right Polyether Conveyor Belt for Your Facility

Not all polyether belts are the same. Factors worth considering include:

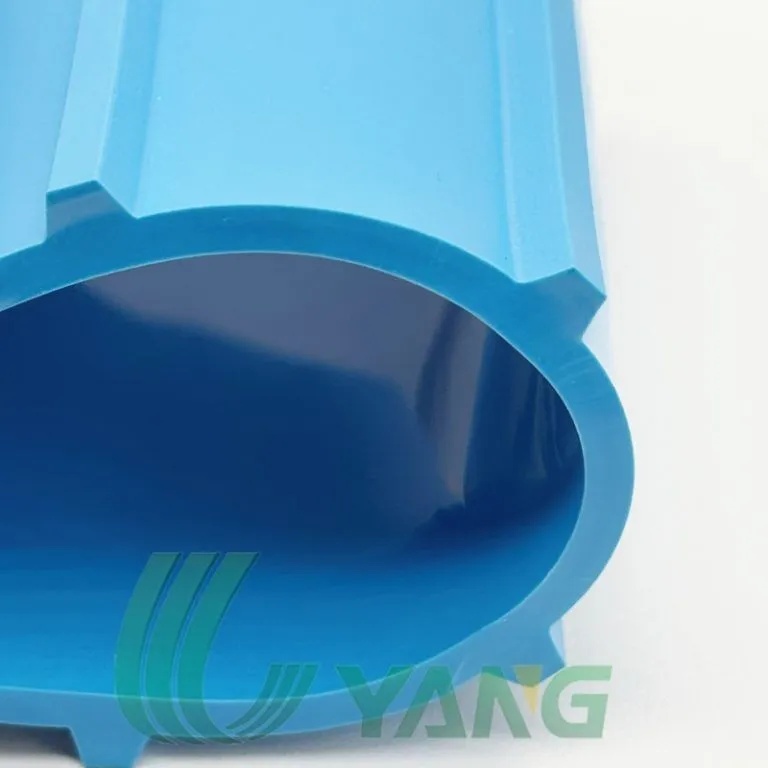

Thickness and rigidity: Meat deboning lines might prefer a thicker, stiffer belt (3–4 mm), while dairy packing lines benefit from thinner, more flexible options.

Cleaning regime: If you rely heavily on chlorine cleaning, choose belts specifically rated for chemical resistance.

Temperature range: Dairy facilities with cold storage conveyors will want belts that stay flexible even at sub-zero conditions.

At UYANG, custom sizing, surface textures, and edge sealing are available. Blue belts are especially popular because they make foreign objects stand out more clearly—a simple but effective food safety feature.

Best Practices for Hygiene Management

Regular Cleaning Protocols

Even the best belt won’t stay hygienic if it’s neglected. Plants should use pH-neutral detergents for daily cleaning, with periodic deep cleans using steam or hot water. One overlooked tip: train operators to inspect belts for knife cuts or fraying edges. Small defects can quickly turn into hygiene nightmares.

Staff Training and Maintenance

Conveyor hygiene isn’t just the responsibility of the cleaning crew. Production workers should know how to spot belt damage or misalignment. Maintenance staff should check tension and joints regularly. UYANG provides manuals and even webinar training on these topics—a small service that reduces costly mistakes.

Conclusion

In meat and dairy production, hygiene isn’t just a compliance requirement—it’s a daily survival skill. Polyether conveyor belts bring together smooth surfaces, chemical resistance, and regulatory approval in one package. They make cleaning faster, reduce contamination risks, and withstand the punishing cycles of modern food plants.

For processors looking to cut downtime, improve safety, and keep auditors happy, polyether belts are a smart investment. Or, as one plant manager told us: “The less time I spend talking about conveyor belts, the better they’re doing their job.”

Talk to our team today about polyether conveyor belt solutions designed for meat and dairy applications.

FAQs

Q1: How long does a polyether conveyor belt usually last in a meat or dairy plant?

Typically 3–5 years, depending on cleaning frequency and load. With proper maintenance, some facilities report even longer service life.

Q2: Are polyether belts more expensive than PVC belts?

Yes, the upfront cost is higher, but they save money in the long run by reducing water, chemicals, labor hours, and replacement frequency.

Q3: Can polyether belts be customized for different food products?

Absolutely. Thickness, texture, color, and edge sealing can all be tailored. Many meat processors prefer textured belts for grip, while dairies often choose smooth blue belts for easy cleaning.