The food factories and hospital must keep clean. Uyang Belting’s antibacterial and anti-mildew hygienic belts can prevent germs and mold. Let’s explore why these belts are so brilliant.

Understanding Cross-Contamination Risks

Cross-contamination refers to the transfer of harmful substances from one object to another. If this occurs in a food factory or pharmaceutical plant, it could cause people to become ill.

Regular belts are like sponges. They soak up water, food bits, or oils. That’s a perfect home for germs and mold to grow! It makes cross-contamination a huge risk. But antibacterial and anti-mildew hygienic belts? They’re built to stop that mess and keep everything clean.

The Role of Antibacterial & Anti-Mildew Hygienic Belts

Why Are These Belts So Clean and Strong?

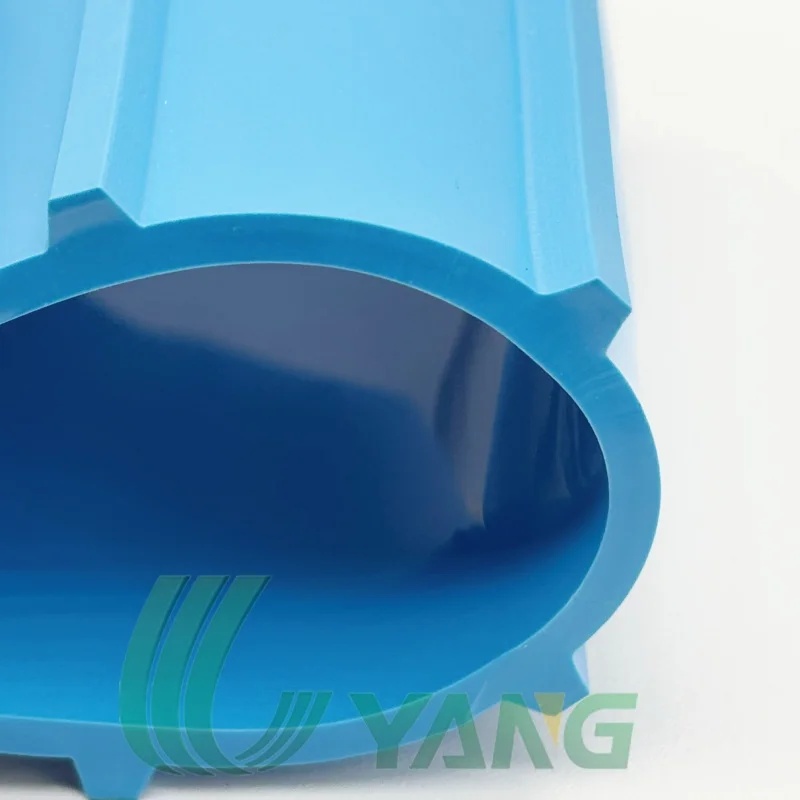

Uyang Belting’s antibacterial and anti-mildew hygienic belts are special. They’re super smooth, with no fabric layers to trap dirt or germs. They’re made from thermoplastic polyurethane (TPU). It’s so slick that germs can’t stick to it! Unlike regular belts that hold water in their layers, these stay dry and clean.

They’re also tough against oils, water, and other gunk. That’s perfect for food or medicine factories where cleanliness is everything. Plus, they can take heavy cleaning—like blasting with water or strong soaps—without breaking. Isn’t that neat?

How Do They Keep Mildew Away?

These belts aren’t just germ-fighters—they stop mildew too! Mildew loves warm, wet spots and can make things stinky or unsafe. Anti-mildew belts stop mold from growing. That keeps your conveyor clean and your products fresh. It’s like having a shield against yucky stuff!

Do They Meet Safety Rules?

You bet! Uyang Belting’s hygienic belts are approved by the FDA and EU. That means they’re safe for touching food. They also follow rules like HACCP, which helps keep food safe. These belts make sure factories pass tough cleanliness checks. How great is that for peace of mind?

Key Applications of Antibacterial and Anti-Mildew Belts

Pemprosesan makanan

Food factories need to be super clean. Conveyor belts touch raw and cooked foods, so they can’t spread germs. Antibacterial belts stop bad bugs like Salmonella from jumping between foods. For example, they keep raw chicken germs away from cooked chicken. Their smooth surface is a breeze to clean, saving factories time and money.

I saw this in action at a local food plant. They switched to Uyang Belting’s belts, and their cleaning crew was thrilled! Less scrubbing meant more time making food.

Pharmaceuticals

Medicine factories have to be squeaky clean to make safe pills or creams. Antibacterial and anti-mildew hygienic belts are used in cleanrooms. They stop germs from sneaking into medicines. Their germ-fighting power keeps everything safe and meets strict rules. Nobody wants a germy pill, right?

Meat and Seafood Processing

Meat and seafood factories have crazy strict rules. Germs or mold can spoil products super fast. Uyang Belting’s antibacterial and anti-mildew hygienic belts are perfect here. They don’t soak up oils or water, which is great for wet places like seafood plants. They keep products safe from start to finish. My friend at a fish market says these belts make their job so much easier!

Dairy and Bakery Industries

Dairy and bakery stuff, like cheese or dough, can be wet and sticky. That’s a germ’s dream home! Antibacterial and anti-mildew belts stop germs from growing. They keep things clean while moving butter or bread dough. This helps factories make safe, tasty treats every day.

Advantages of Uyang Belting’s Antibacterial & Anti-Mildew Hygienic Belts

Are They Super Tough?

Oh yeah! These belts are like tanks. They handle cuts, bumps, and germ attacks like champs. They last way longer than regular belts. They might cost a bit more upfront, but you save cash over time. You won’t need to fix or replace them as often. That’s a big win!

Are They Easy to Clean?

Totally! Their smooth, non-porous surface stops dirt and germs from sticking. You can clean them quick with water or soap. That saves tons of time in busy factories. Less cleaning means more time making stuff. Who doesn’t love that?

Can You Make Them Your Way?

Yup! Uyang Belting lets you choose the belt’s thickness, color, or texture. Blue belts are a hit in food factories because dirt shows up easily. You can pick textures for sticky stuff like dough. This makes the belt perfect for your factory’s needs. How handy is that?

How to Choose the Right Antibacterial & Anti-Mildew Belt

Here’s what to think about when picking a belt:

What Material Is Best?

TPU is the way to go! It’s super strong and stops germs from growing. It’s awesome for tough places like meat or medicine factories.

How Thick Should the Belt Be?

For heavy stuff like meat or poultry, pick thicker belts, like 3-4mm. They can handle the weight. For lighter things like bakery goods, a 2mm belt works great. Choose what fits your machines best.

Why Does Splicing Matter?

Go for belts with seamless heat-fusion splicing. It stops germs from hiding in joints. That keeps your belt super clean and safe. No sneaky spots for bad stuff!

Why Sesuaikan Your Belt?

Pick a color or texture that works for your factory. Blue belts make it easy to spot dirt. Textured belts are great for sticky stuff like dough.

FAQs

Q1: What industries benefit the most from antibacterial and anti-mildew hygienic belts?

A: Antibacterial and anti-mildew hygienic belts are essential for industries such as food processing, pharmaceuticals, meat and seafood processing, dairy, and bakery production, where hygiene and safety are critical.

Q2: How do antibacterial belts reduce cleaning time?

A: These belts have a smooth, non-porous surface that prevents dirt, oils, and moisture from sticking, making them easier to clean. This reduces cleaning time and minimizes downtime during production.

Q3: Are antibacterial belts more expensive than traditional belts?

A: While the initial investment in antibacterial belts may be higher, their long lifespan, ease of maintenance, and reduced cleaning costs provide a cost-effective solution in the long term.