- Rumah

- Produk

- Industri & Aplikasi

- Mengenai

- Hubungi

MS

MS

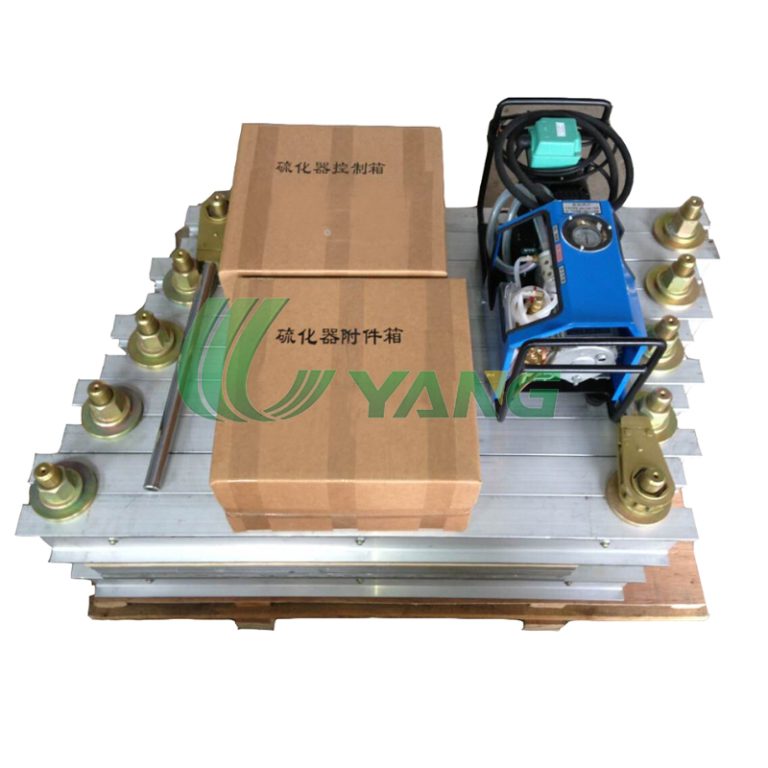

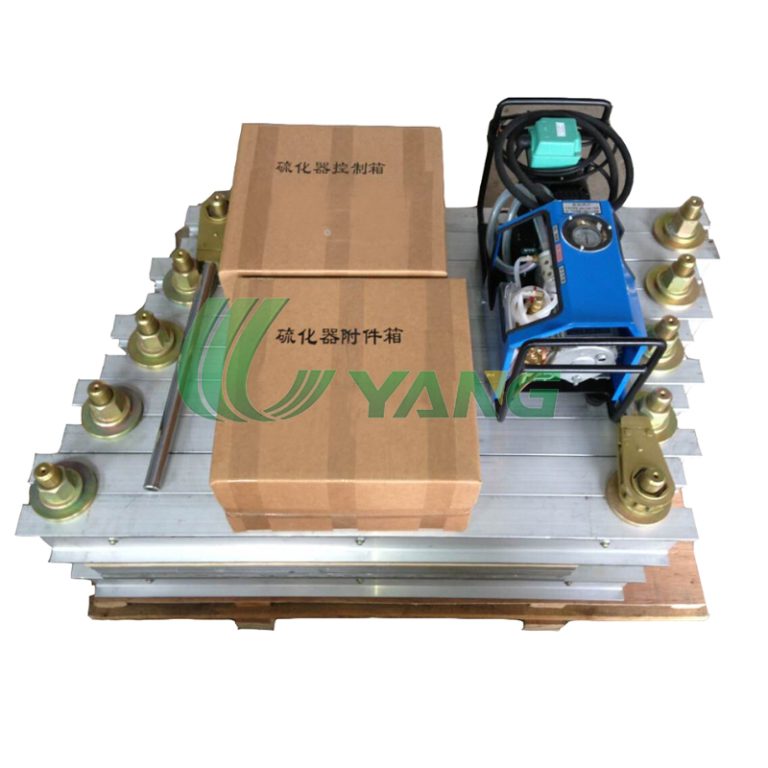

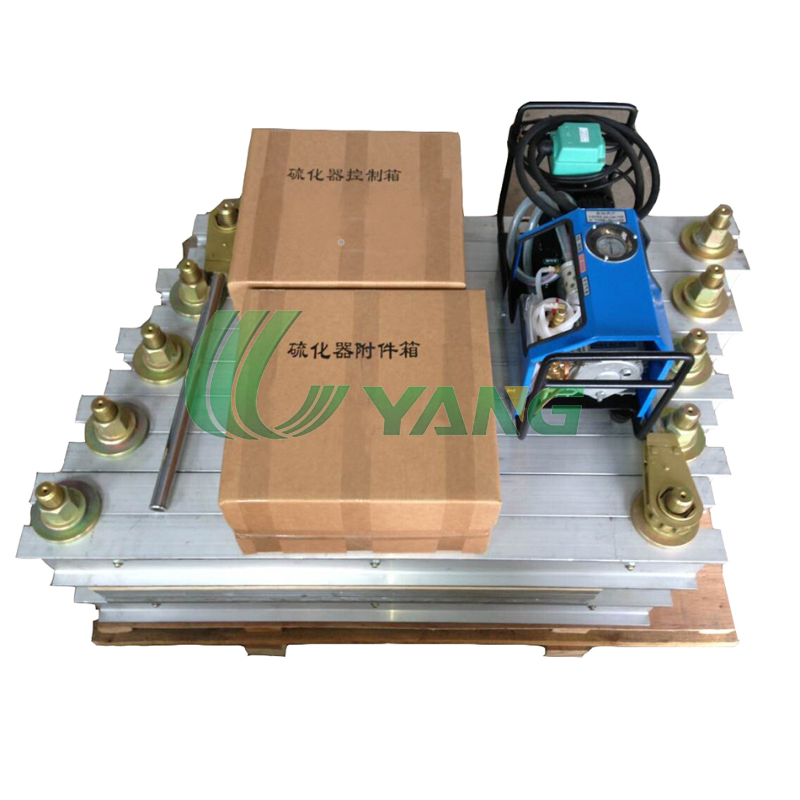

The UYCBV Series Conveyor Belt Vulcanizer is a portable and efficient splicing press designed for on-site vulcanization of rubber conveyor belts, including fabric, nylon, and steel cord types. Featuring uniform heating, stable pressure (0–1.5 MPa), and an integrated control cabinet, it ensures high-quality joints with minimal downtime. Widely used in mining, metallurgy, power plants, ports, and cement industries.

The UYCBV Series Conveyor Belt Vulcanizer is a portable and efficient splicing press designed for on-site vulcanization of rubber conveyor belts, including fabric, nylon, and steel cord types. Featuring uniform heating, stable pressure (0–1.5 MPa), and an integrated control cabinet, it ensures high-quality joints with minimal downtime. Widely used in mining, metallurgy, power plants, ports, and cement industries.

Portable Design – Compact and lightweight for easy transport and setup.

Uniform Heating – Ensures consistent vulcanization across the splice area.

Even Pressure – Stable pressure system (0–1.5 MPa) for strong, reliable joints.

Easy Operation – Plug-and-play control cabinet with integrated cables.

Wide Application – Suitable for various belt types and heavy industries.

Reliable On-Site Splicing for All Types of Rubber Belts

The UYCBV Conveyor Belt Vulcanizer is a versatile, field-ready vulcanizing press designed for high-efficiency splicing of rubber conveyor belts. Compact in size and lightweight for easy transport and installation, the UYCBV is ideal for on-site maintenance and emergency repairs.

Equipped with a uniform heating system and well-distributed pressure (0–1.5 MPa), this press ensures strong, durable belt joints. The integrated control cabinet and multi-core plug system allow for safe, stable, and efficient operation—with minimal maintenance.

Technical Parameters

Lightweight and portable for easy on-site setup

Uniform temperature and pressure for high joint quality

Automatic control cabinet with plug-and-play cable system

Suitable for canvas, nylon, steel cord, and heat/chemical-resistant belts

Widely used in mining, metallurgy, power plants, ports, cement, and more

Non-explosive and corrosion-safe environments only

Why It Matters:

The quality of a belt splice directly impacts conveyor performance and belt lifespan—especially for long-distance and high-strength systems. The UYCBV Vulcanizing Press is an essential tool for ensuring reliable, high-performance belt joints.

Jadual penghantaran yang boleh dipercayai dan sokongan pergudangan.

Harga kompetitif untuk memaksimumkan nilai keseluruhan.

Pelbagai pilihan untuk memenuhi semua segmen pasaran.

Sokongan MOQ yang fleksibel dengan semua jenis barang;

Penyesuaian logo yang diperibadikan pada produk

Sediakan sokongan teknikal dalam talian untuk semua proses penggunaan dan pemasangan produk

Respons pertama yang cepat untuk semua pertanyaan dan soalan

Berikan imej yang berkualiti, video untuk meningkatkan pendapatan jualan

Pengeluaran dan kapal yang cekap dalam masa 15 hari di yang terpantas.

Umumnya 10-15 hari, jika musim puncak, kira-kira 15-20 hari Safter menerima deposit

1. Spesifikasi yang disahkan: ketebalan, warna, plies, ciri, dan industri;

2. Sampel Menghantar: Kami menghantar sampel untuk anda check.or anda menghantar sampel kepada kami jika tali pinggang tersuai.

3. Sahkan Pesanan: Menandatangani Kontrak Jualan Selepas Sampel Disahkan.

4. Deposit: Deposit 30% sebelum pengeluaran besar -besaran.

5. Pengeluaran diatur: Kami akan memproses pengeluaran.

6. Baki pembayaran: Selepas pemeriksaan, baki sebelum penghantaran.

7. Penghantaran: Kami akan menghantar barang ke pelabuhan destinasi.

8. Sahkan bil pemuatan {{url_placeholder_0}} invois {{url_placeholder_1}} list {{url_placeholder_2}} dari asal;