- Rumah

- Produk

- Industri & Aplikasi

- Mengenai

- Hubungi

MS

MS

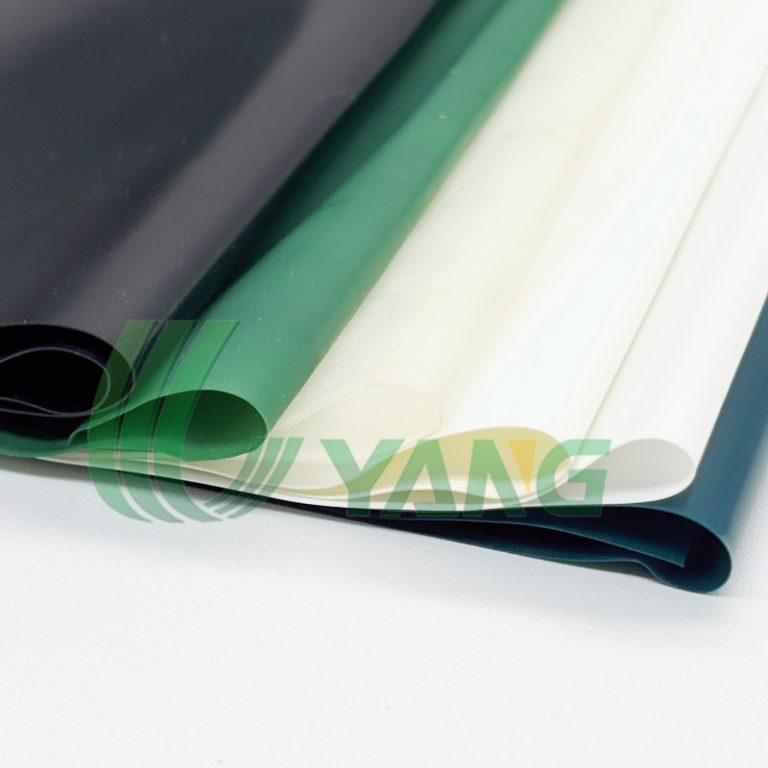

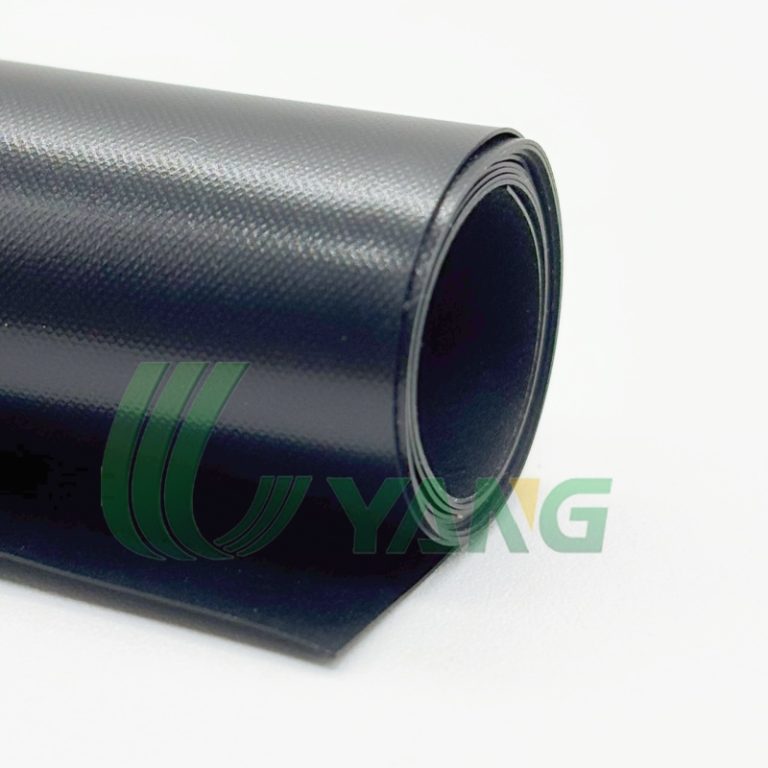

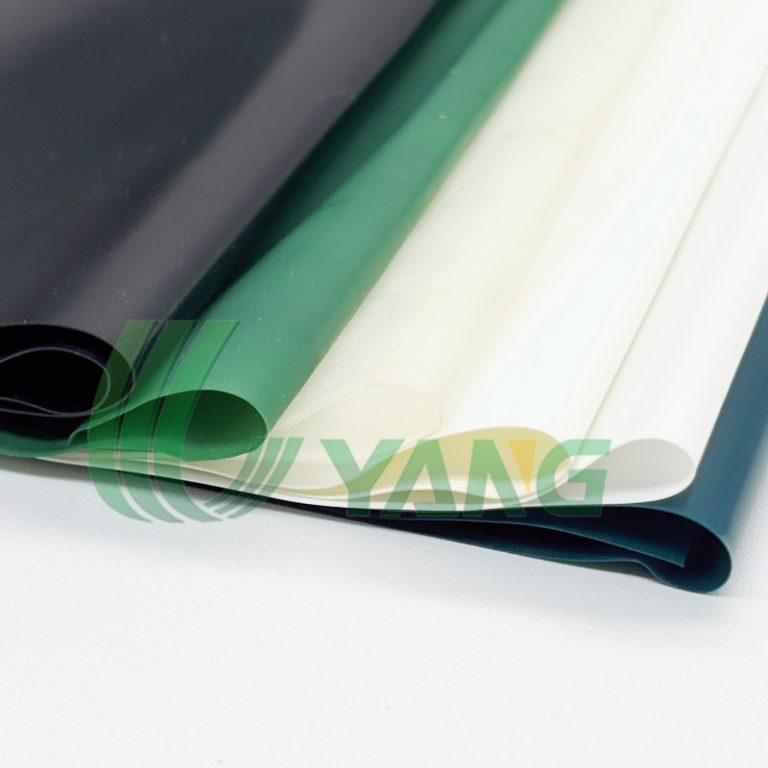

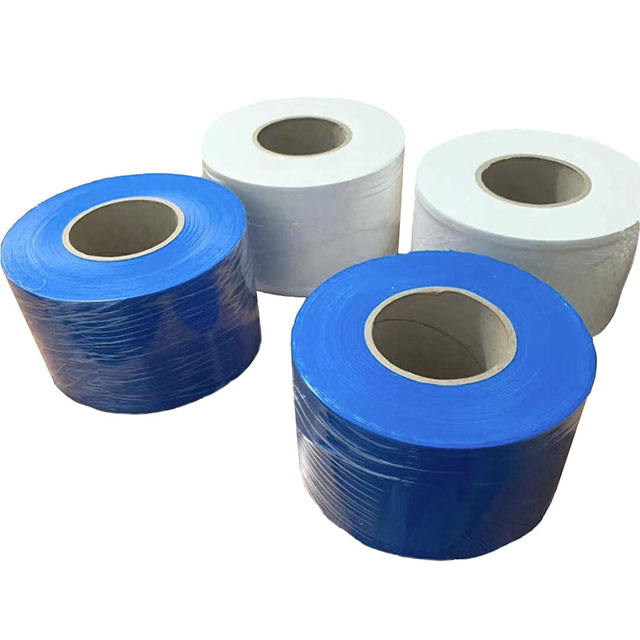

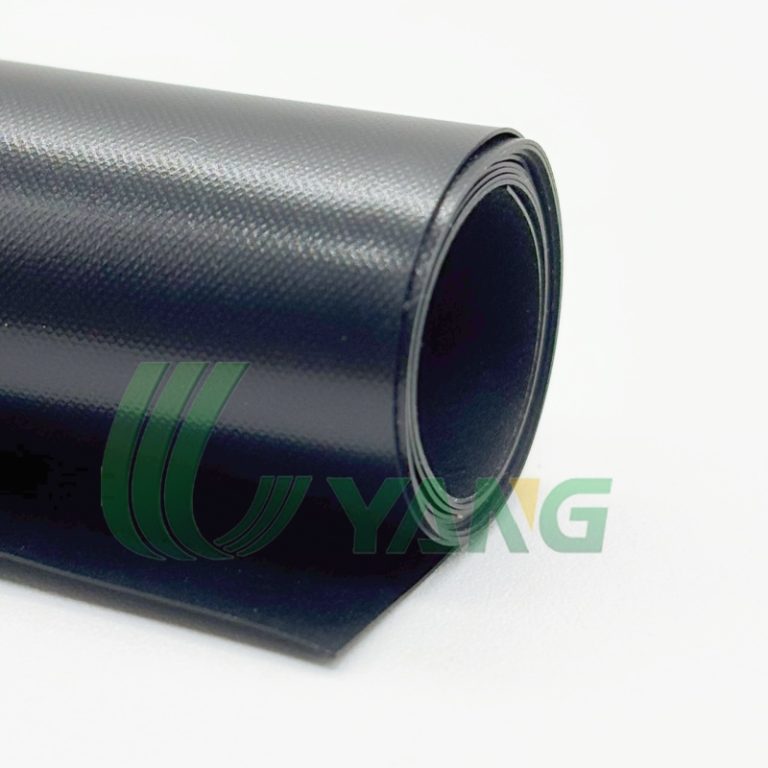

UYANG BELTING PVC/PU splice film is engineered for reliable splicing of PVC and PU conveyor belts — producing smooth, low-profile joints that maintain belt strength and tracking. Available in multiple colors for easy identification and seamless aesthetics.

UYANG BELTING PVC/PU splice film is engineered for reliable splicing of PVC and PU conveyor belts — producing smooth, low-profile joints that maintain belt strength and tracking. Available in multiple colors for easy identification and seamless aesthetics.

Kelebihan utama:

Strong & Durable – ensures reliable, long-lasting belt splicing.

Easy to Use – smooth welding for clean, low-profile joints.

Color Options – blue, black, green, and white for coding and visual management.

Key benefits

Produces clean, low-profile splices that reduce product catch points and contamination.

Color options (blue/black/green/white) help with line coding, hygiene zones and visual inspection.

Good wear and abrasion resistance to match belt performance.

Easy to weld or fuse with standard splicing methods (hot air, hot-press/vulcanization, or compatible welding processes).

Improves splice consistency and durability compared with untreated joints.

Custom widths and thicknesses available to suit different belt types and joint requirements.

Food-grade formulations available on request for hygiene-sensitive lines.

Typical specifications (examples — customizable)

Material: PVC or PU splice film (select by application)

Thickness: 0.2 mm — 1.0 mm (common sizes; custom on request)

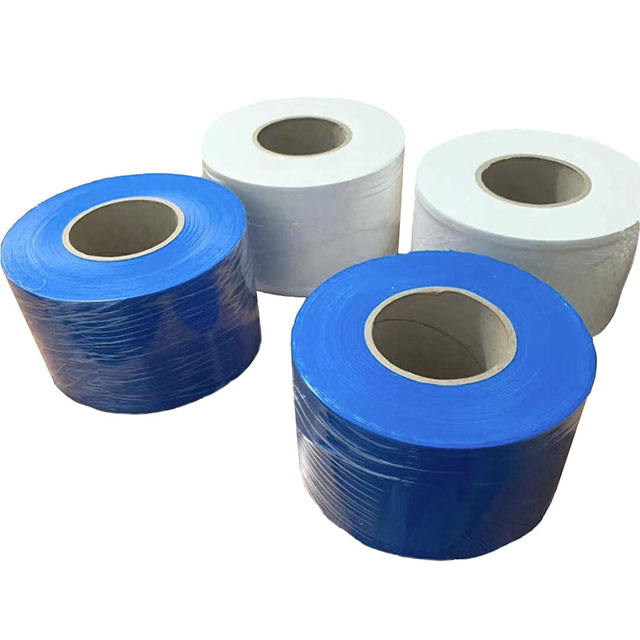

Size: 100mm*100M/Roll;

Colors: Blue, Black, Green, White

Temperature resistance: suitable for normal washdown and processing environments (spec depends on selected material grade)

Packaging: rolls or pre-cut sheets/strips for on-site splicing

Aplikasi

Splicing of PVC/PU conveyor belts in food processing, packaging, logistics and light industry.

Quick field repairs and factory splices for production lines.

Color-coded conveyor zones (e.g., raw vs. cooked, allergen control, sanitation areas).

Installation & usage notes

Clean and prepare belt ends—remove debris and ensure even edges.

Position splice film between belt ends; align carefully for tracking.

Use the recommended splicing method for your belt material (hot-press/vulcanization, hot-air welding, or compatible fusion technique).

Allow joint to cool/cure fully before loading.

Inspect splice for smoothness and alignment; trim or reseal edges if needed.

Why choose our splice film

Color-coded, durable and easy-to-use — our PVC/PU splice films give you reliable, professional joints that keep conveyors running cleaner and smoother while supporting quick repairs and consistent manufacturing standards.

Jadual penghantaran yang boleh dipercayai dan sokongan pergudangan.

Harga kompetitif untuk memaksimumkan nilai keseluruhan.

Pelbagai pilihan untuk memenuhi semua segmen pasaran.

Sokongan MOQ yang fleksibel dengan semua jenis barang;

Penyesuaian logo yang diperibadikan pada produk

Sediakan sokongan teknikal dalam talian untuk semua proses penggunaan dan pemasangan produk

Respons pertama yang cepat untuk semua pertanyaan dan soalan

Berikan imej yang berkualiti, video untuk meningkatkan pendapatan jualan

Pengeluaran dan kapal yang cekap dalam masa 15 hari di yang terpantas.

Umumnya 10-15 hari, jika musim puncak, kira-kira 15-20 hari Safter menerima deposit

1. Spesifikasi yang disahkan: ketebalan, warna, plies, ciri, dan industri;

2. Sampel Menghantar: Kami menghantar sampel untuk anda check.or anda menghantar sampel kepada kami jika tali pinggang tersuai.

3. Sahkan Pesanan: Menandatangani Kontrak Jualan Selepas Sampel Disahkan.

4. Deposit: Deposit 30% sebelum pengeluaran besar -besaran.

5. Pengeluaran diatur: Kami akan memproses pengeluaran.

6. Baki pembayaran: Selepas pemeriksaan, baki sebelum penghantaran.

7. Penghantaran: Kami akan menghantar barang ke pelabuhan destinasi.

8. Sahkan bil pemuatan {{url_placeholder_0}} invois {{url_placeholder_1}} list {{url_placeholder_2}} dari asal;