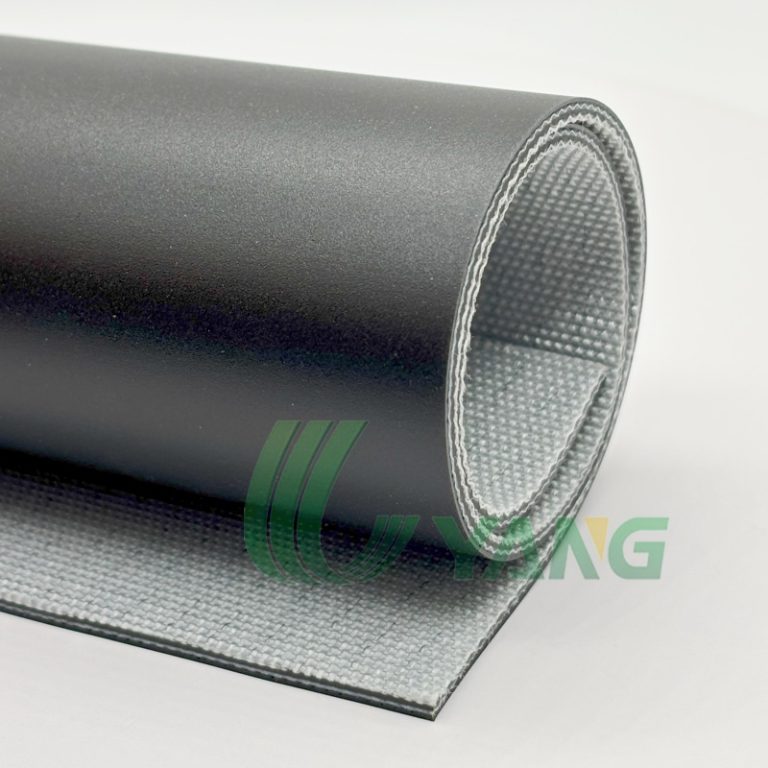

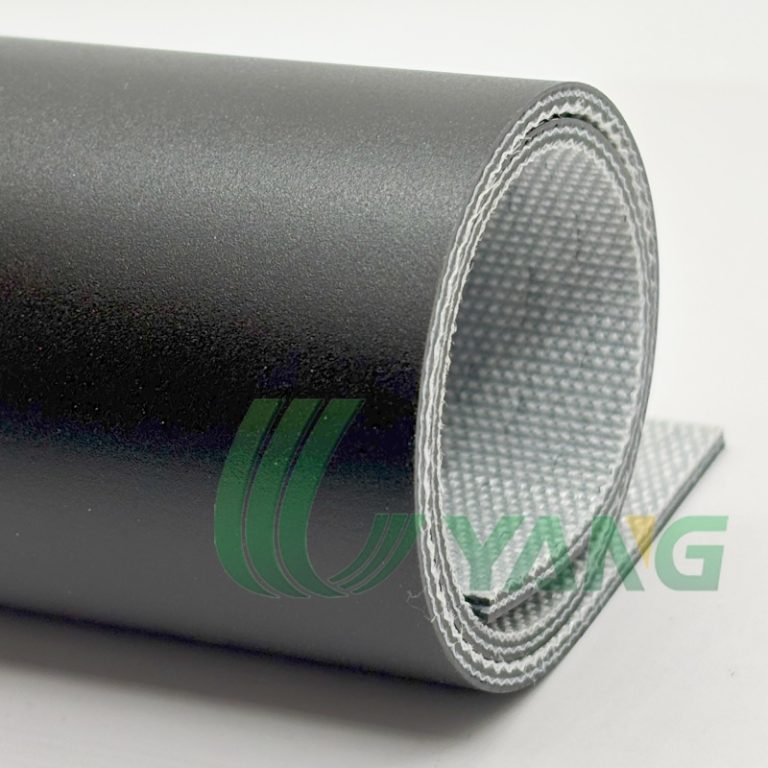

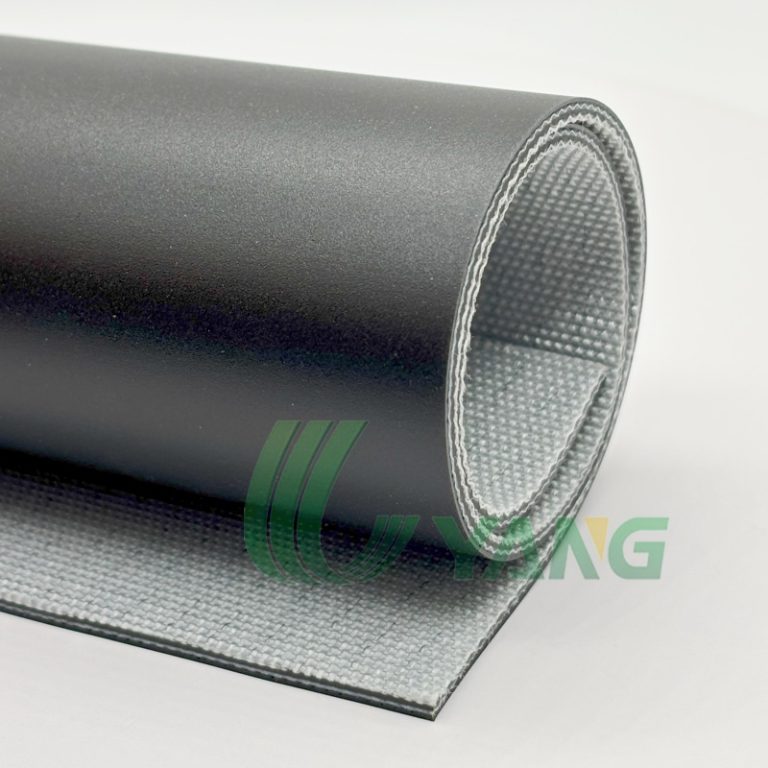

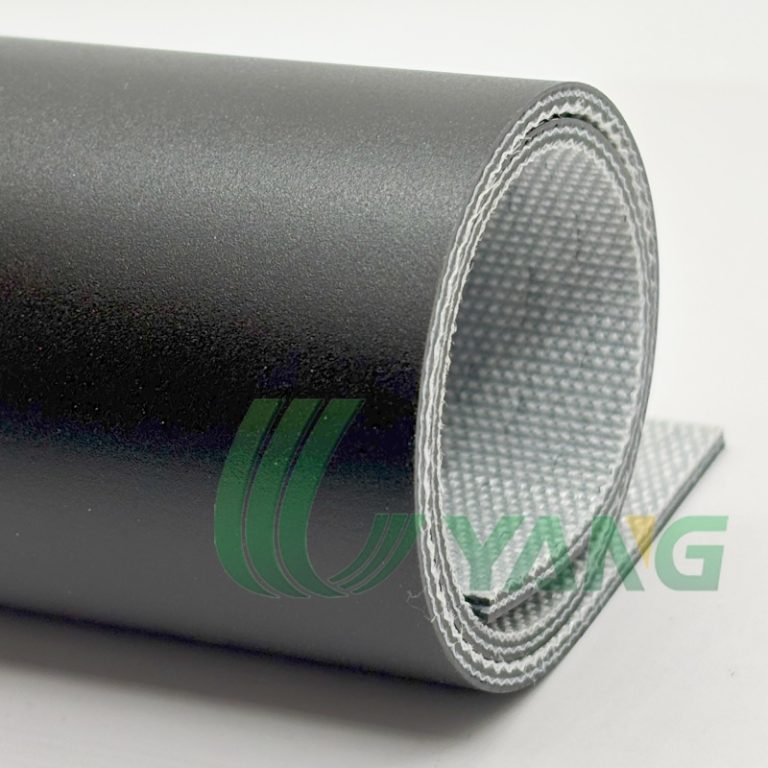

Uyang Belting Black Matte PVC Checkout Conveyor Belt is specially designed for supermarket and retail checkout counters.

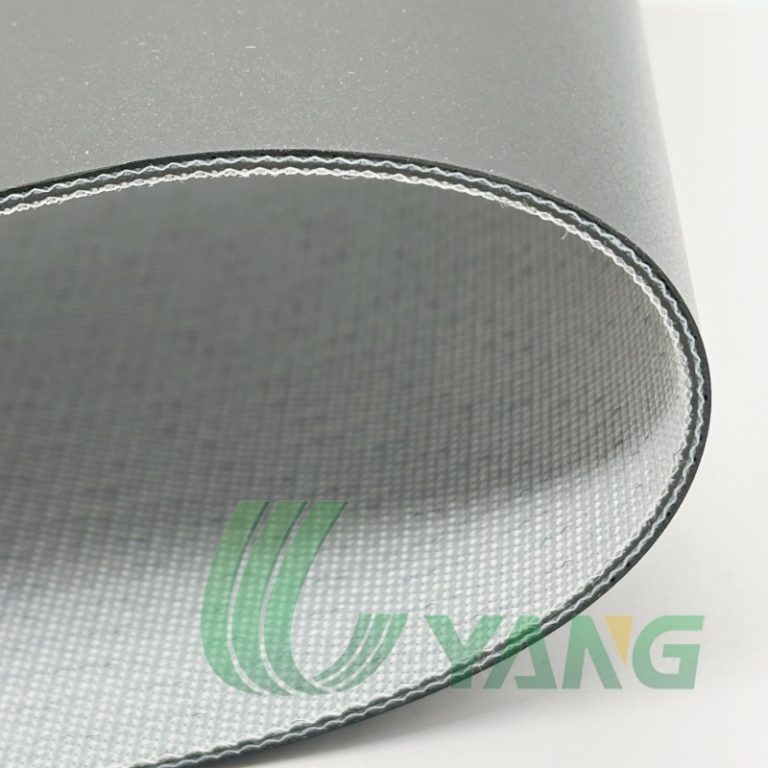

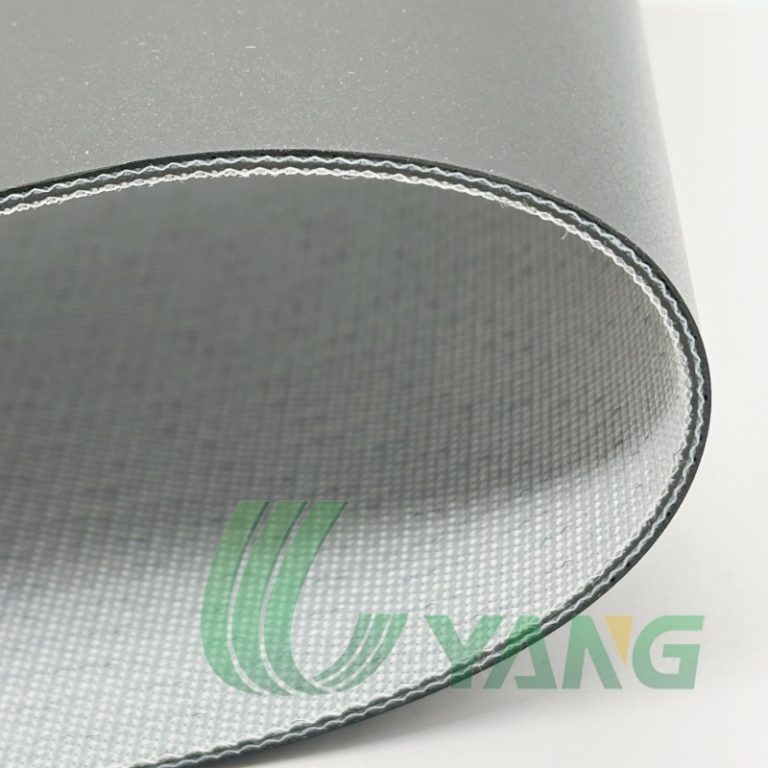

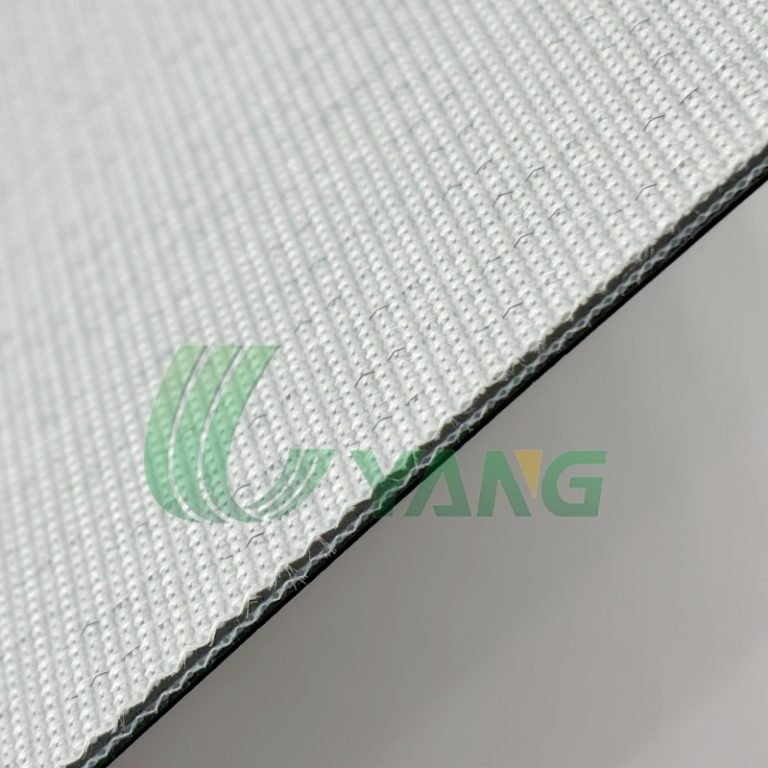

With an antistatic matte PVC surface 그리고 a low-noise fabric backing, this belt ensures smooth operation, durability, and a comfortable checkout experience for both customers and cashiers. Available in 2.0 mm and 3.0 mm thicknesses, it combines functionality with a professional appearance.

Uyang Belting Black Matte PVC Checkout Conveyor Belt is specially designed for supermarket and retail checkout counters.

With an antistatic matte PVC surface 그리고 a low-noise fabric backing, this belt ensures smooth operation, durability, and a comfortable checkout experience for both customers and cashiers. Available in 2.0 mm and 3.0 mm thicknesses, it combines functionality with a professional appearance.

Antistatic Surface – Prevents static build-up and reduces dust attraction.

Matte Finish – Elegant black matte appearance, non-reflective, fits retail environments.

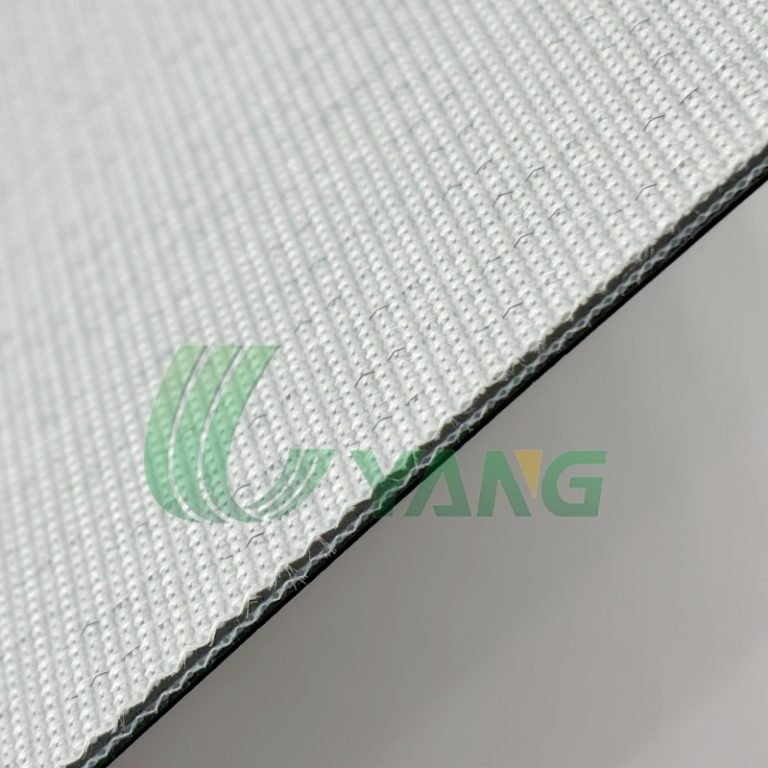

Low-Noise Fabric Backing – Ensures quiet operation, improving checkout comfort.

Durable & Easy to Clean – Resistant to wear, dirt, and easy to maintain.

사용자 정의 가능 – Available in different widths, lengths, and logo printing.

| 목 | Value / Options |

|---|---|

| 두께 | 2.0 mm / 3.0 mm |

| Top Cover | PVC, Antistatic Surface; |

| Surface Finish | Black Matte |

| Bottom Layer | Low-noise Fabric Backing |

| Width Range | 100 mm – 3400 mm (customizable) |

| 길이 | Supplied by roll or cut to size or endless ; |

| 온도 범위 | -20°C to +80°C |

| Joint Options | Hot splicing / Mechanical fastener |

| 애플리케이션 | Supermarket & Bank & Retail Checkout Counters |

Supermarket checkout counters

Retail stores and convenience stores

Self-checkout counters

Q1: What thicknesses are available?

A: Standard thicknesses are 2.0 mm 그리고 3.0 mm. Other thicknesses (e.g., 1.5 mm, 2.5 mm, 4.0 mm) can be produced on request— don’t hesitate to get in touch with sales for availability.

Q2: Is the surface antistatic?

A: Yes — the top PVC layer receives antistatic treatment. Surface resistivity can be adjusted to meet specific ESD requirements (provide target Ω/□ range, and we can test).

Q3: What is the backing material? Does it reduce noise?

A: The bottom is a low-noise fabric backing designed to reduce running noise and provide stable support for light-load checkout use.

Q4: What widths and lengths can you supply?

A: Typical widths range from 100 mm to 3400 mm (custom widths available). Supplied by the meter on rolls or cut-to-length per order.

Q5: What joint/splice methods do you recommend?

A: For the smoothest appearance, we recommend hot splicing (heat weld). Mechanical fasteners (steel fasteners) are available when on-site equipment prevents hot splicing.

Q6: How do I clean and maintain the belt?

A: Clean with a soft cloth and neutral detergent; avoid strong acids/alkalis and sharp tools. Regularly inspect for debris on rollers and check splice areas for wear.

Q7: Is this belt suitable for high-speed or heavy-load applications?

A: This product is designed for checkout/light-load, low-to-moderate speed applications. For heavy loads or continuous high-speed conveying, request our recommended industrial belt options.

Q8: Can you print logos or lines on the belt?

A: Yes — logo printing, guide lines, or demarcation stripes can be added. Please provide artwork and confirm quantities for print setup.

Q9: What is the sample policy and lead time?

A: Sample lead time: typically 3–7 business days (depending on customization).

Production lead time: standard items 10–20 business days after deposit and sample approval; custom orders 20–35 business days.

Q10: What are payment and shipping terms?

A: Typical terms: 30% T/T deposit, 70% balance before shipment. We ship by sea, air, or courier. Incoterms commonly used: FOB (port of loading) by default; CIF/DDP available on request.

Q11: What warranty do you provide?

A: We offer a 12-month warranty against manufacturing defects under normal use. For claims, provide photos and notify us within the claim window (visible damage on delivery: within 7 days; hidden defects: within 14 days).

Q12: What is the minimum order quantity (MOQ)?

A: MOQ depends on specifications and customization. Small/sample orders are accepted but pricing may differ. Please contact sales with required width, thickness, length and quantity for a quote.

Q13: Are there any temperature or chemical limitations?

A: Typical working temperature range is –20°C to +80°C. Avoid prolonged exposure to strong solvents, concentrated acids or alkalis—consult us if your application involves chemicals.

Q14: Do you provide pre-shipment inspection and test reports?

A: Yes — pre-shipment inspection can be arranged. Surface resistivity, tensile, and other test reports can be provided upon request (may incur testing fees).

Q15: How do I get a quote or place an order?

A: Contact our sales team with your required thickness, width, length, quantity, and any customization (printing/ESD specs) — email: info.uyangbelting@tj-uyang.com or click Request a Quote on the contact page. We’ll reply with price, MOQ, lead time, and shipping options.

신뢰할 수있는 배송 일정 및 창고 지원.

전체 가치를 극대화하기위한 경쟁력있는 가격.

모든 시장 부문을 수용 할 수있는 다양한 옵션.

모든 유형의 상품에 대한 유연한 MOQ 지원;

제품에 대한 개인화 된 로고 사용자 정의

모든 제품 사용 및 설치 프로세스에 대한 온라인 기술 지원 제공

모든 질문과 질문에 대한 빠른 첫 번째 응답

판매 수익을 향상시키기위한 품질의 이미지, 비디오를 제공합니다

15 일 이내에 효율적인 생산 및 배송.

일반적으로 10-15 일, 성수기 인 경우 예금을받는 약 15-20 일 안전입니다.

1. 확인 된 사양 : 두께, 색상, 플라이, 특성 및 산업;

2. 샘플 보내기 : 우리는 당신을 위해 샘플을 보냅니다.

3. 주문 확인 : 샘플 확인 후 판매 계약 서명.

4. 예금 : 대량 생산 전 30% 예금.

5. 생산 준비 : 우리는 생산을 처리 할 것입니다.

6. 나머지 지불 : 검사 후 배송 전 잔액.

7. 배송 : 우리는 상품을 목적지 포트로 배송합니다.

8. 로딩 청구서 확인 {{url_placeholder_0}} invoice {{url_placeholder_1}} list {{url_placeholder_2}}};