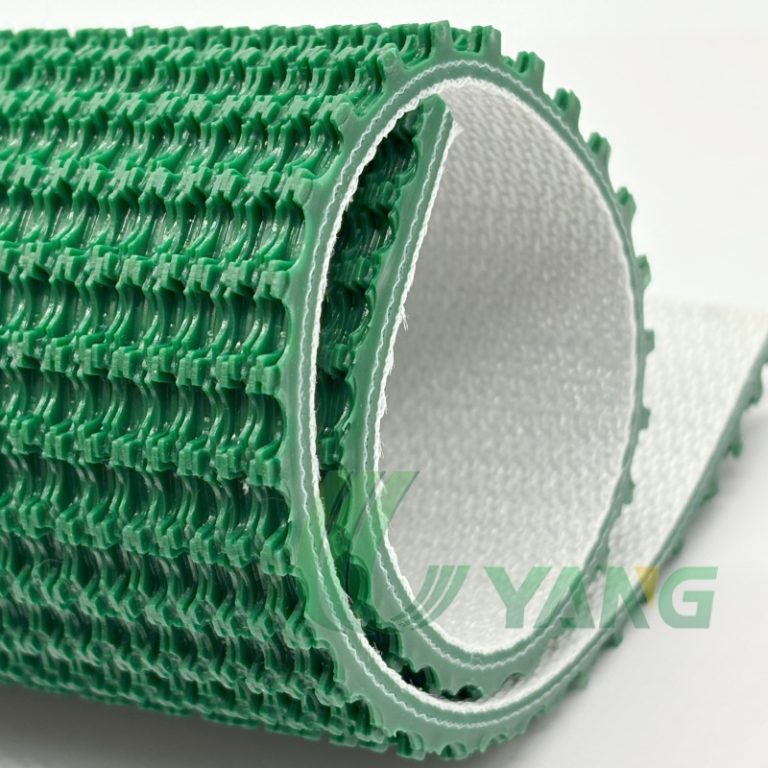

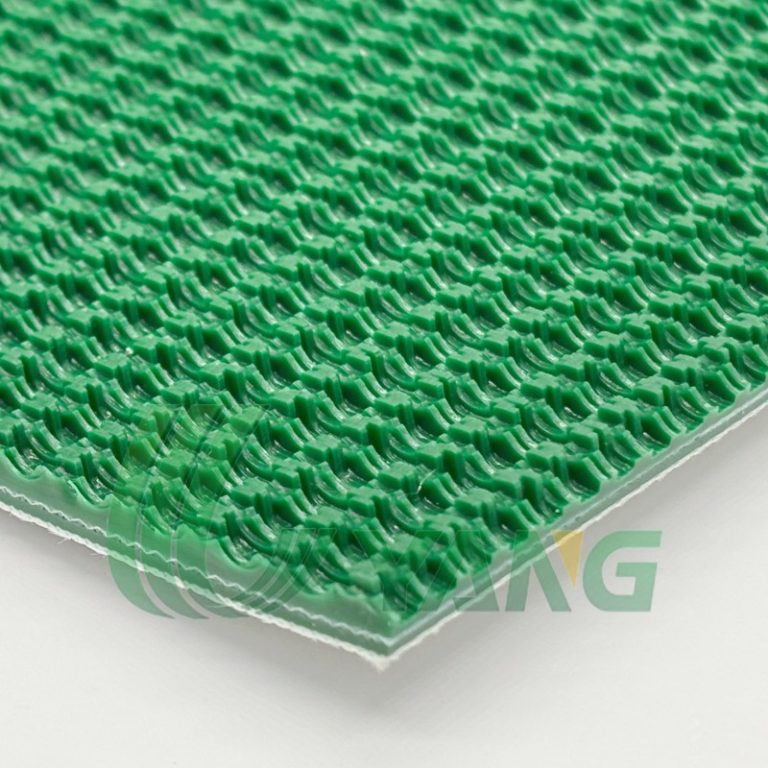

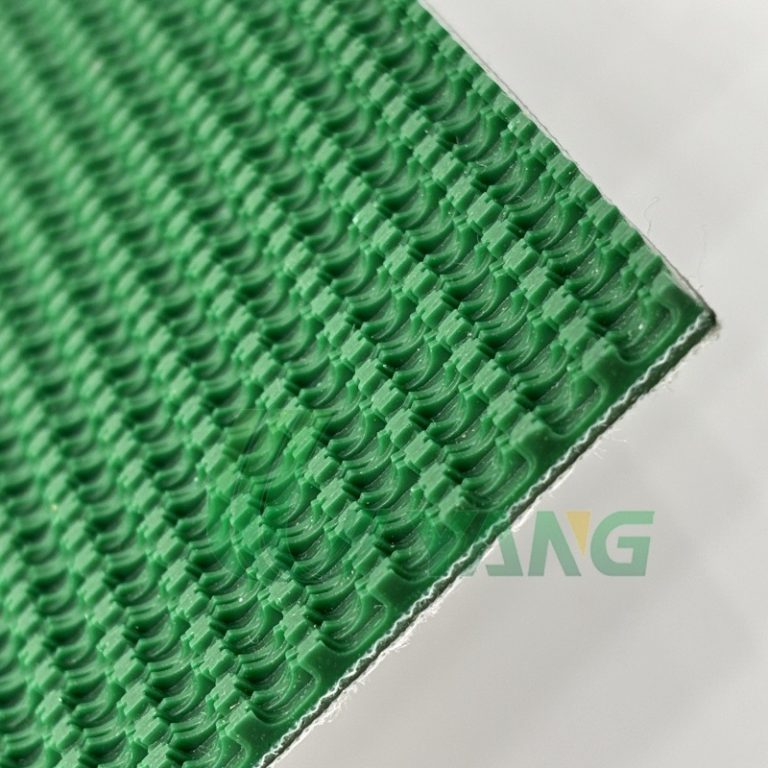

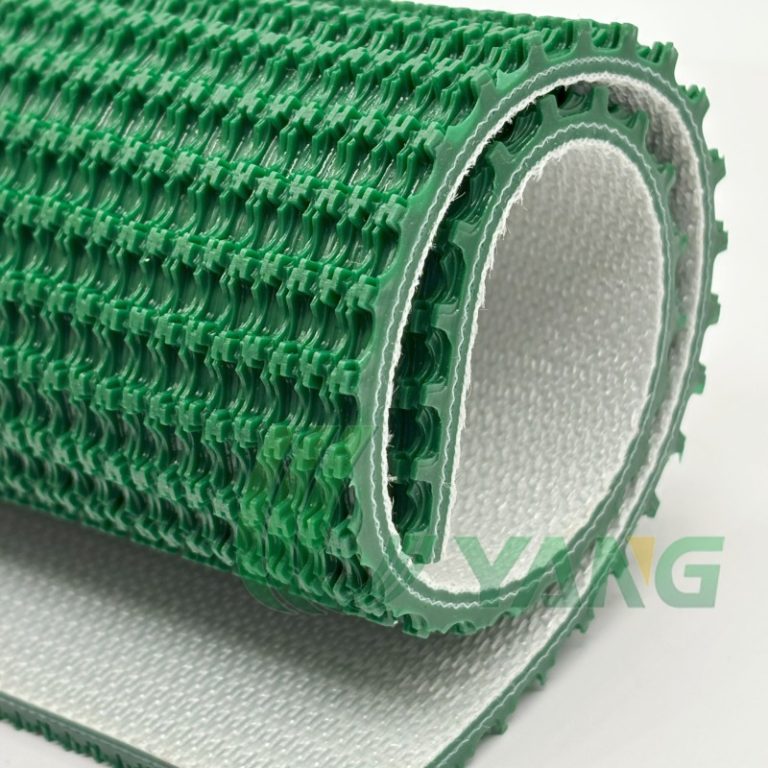

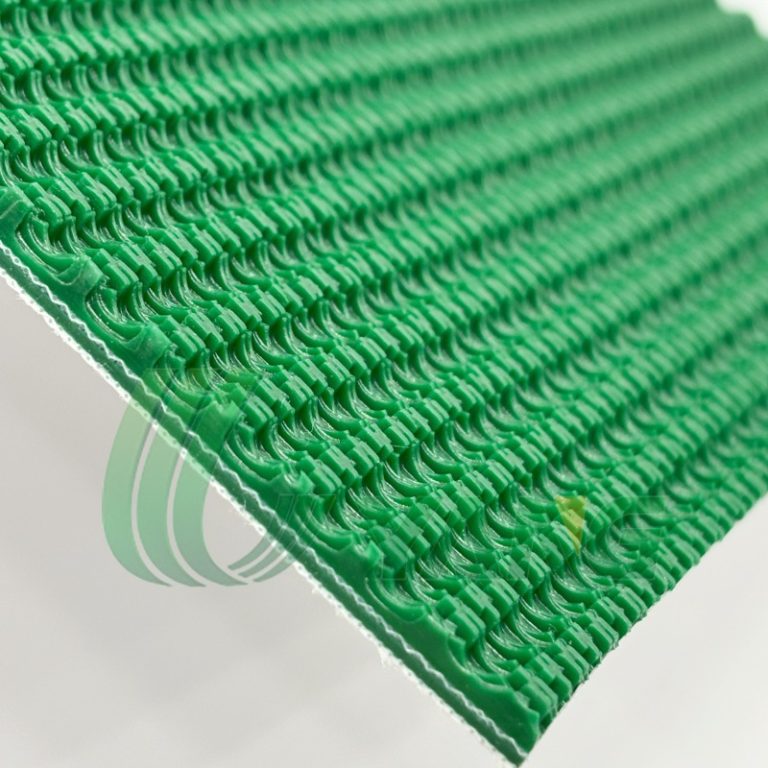

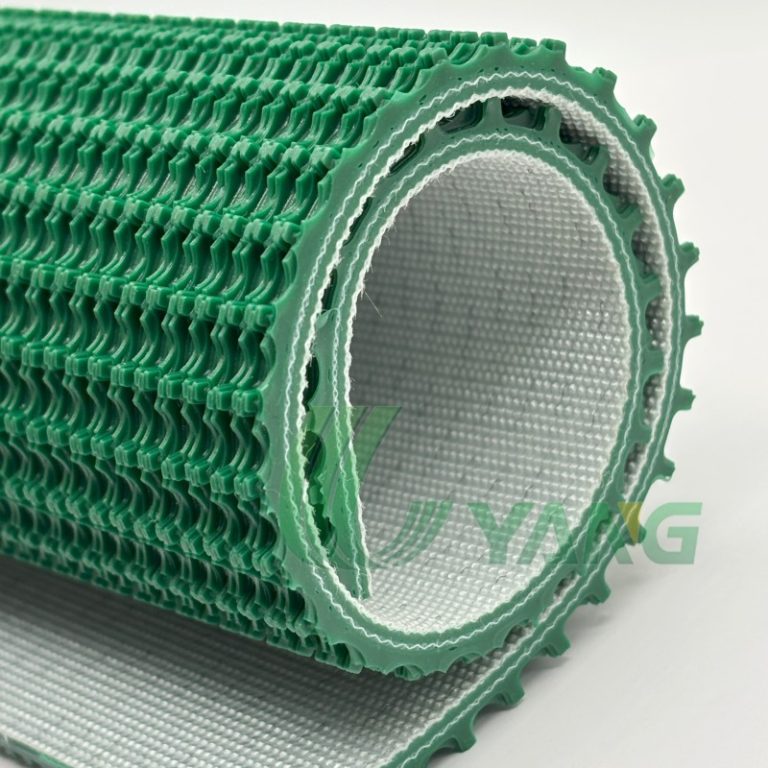

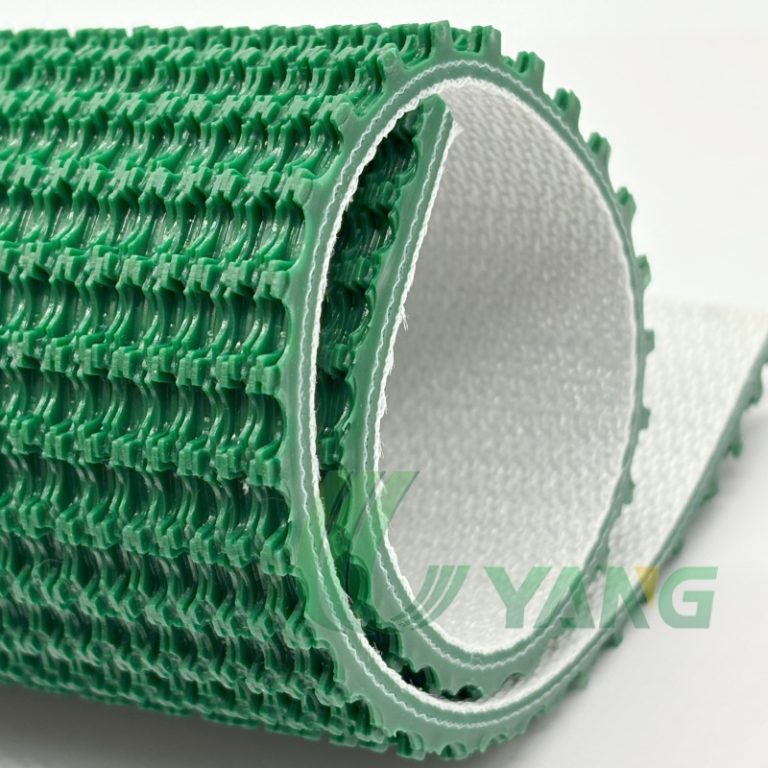

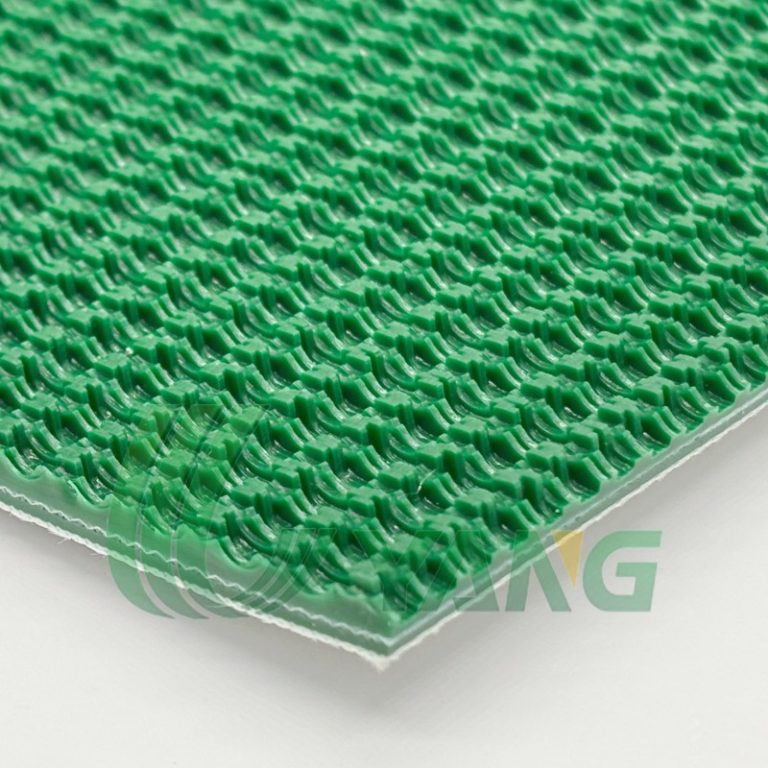

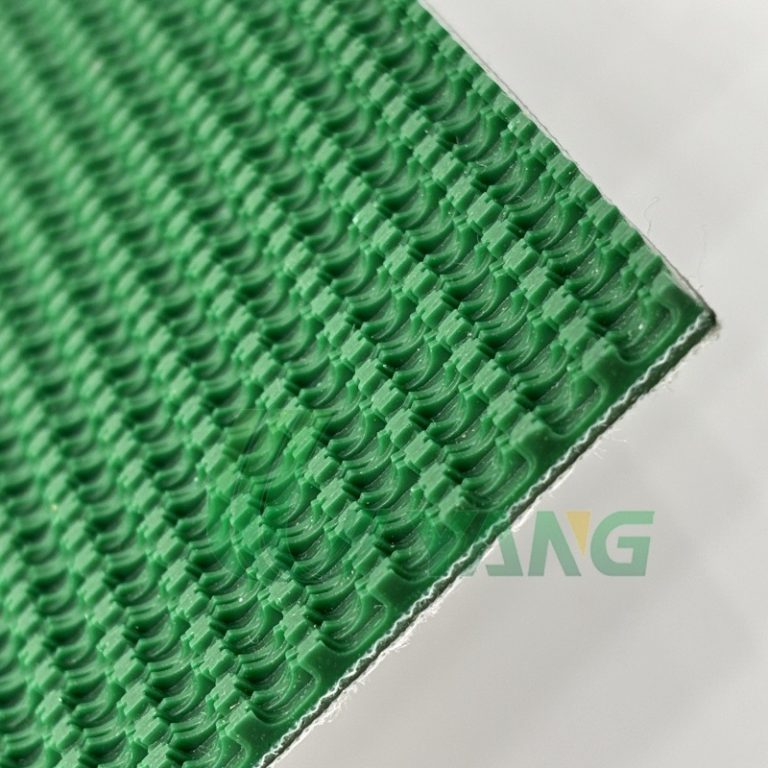

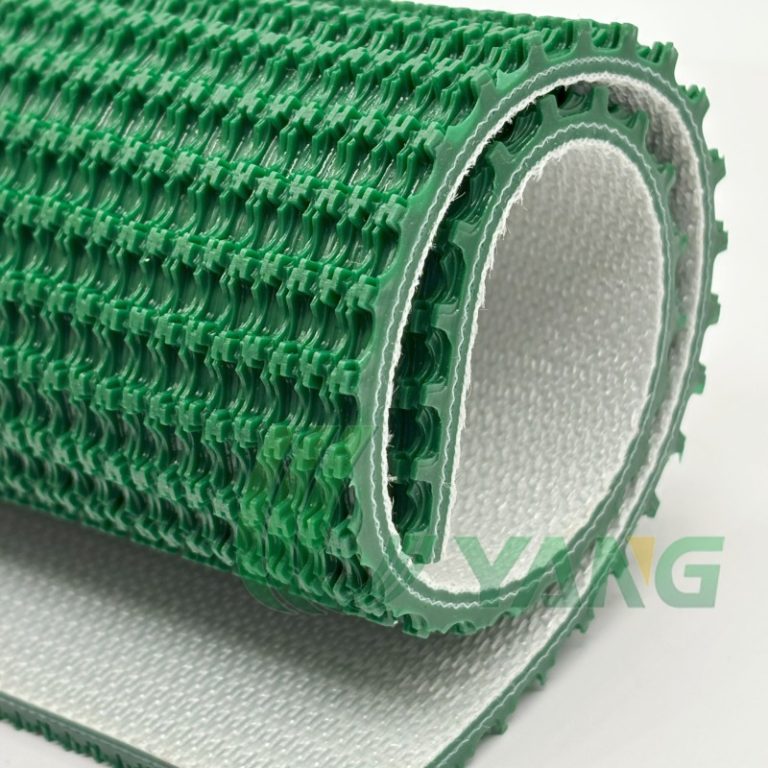

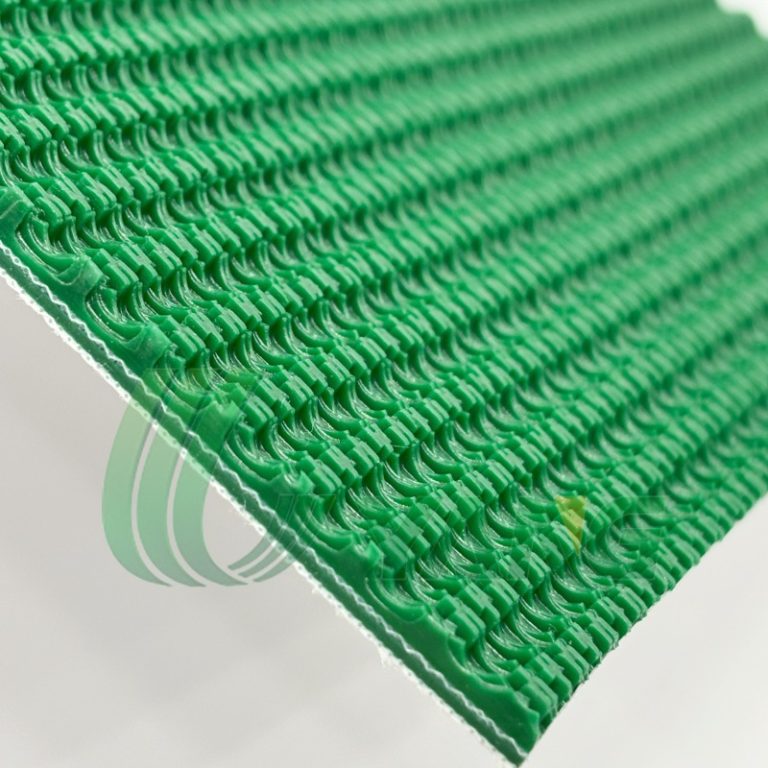

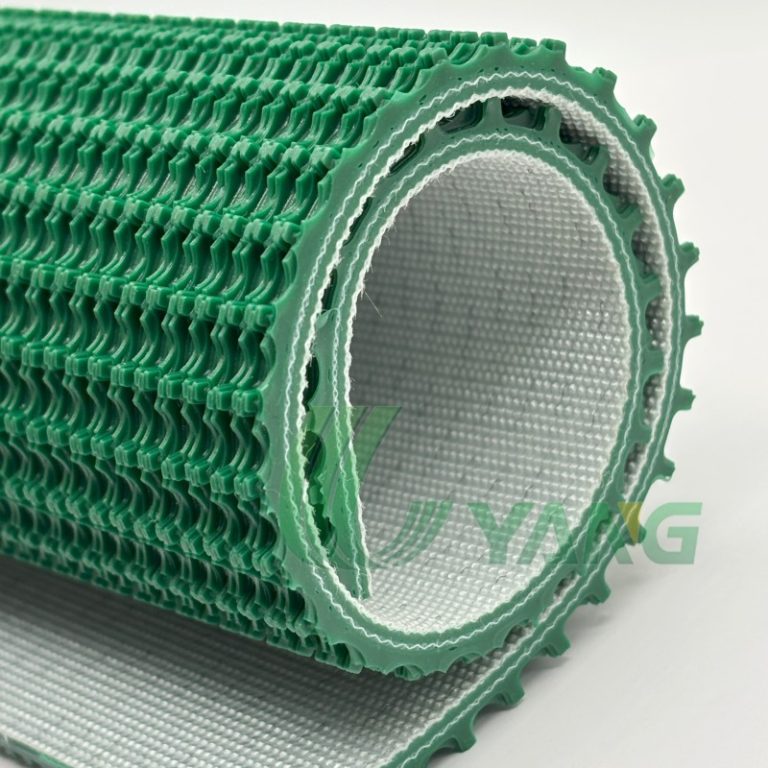

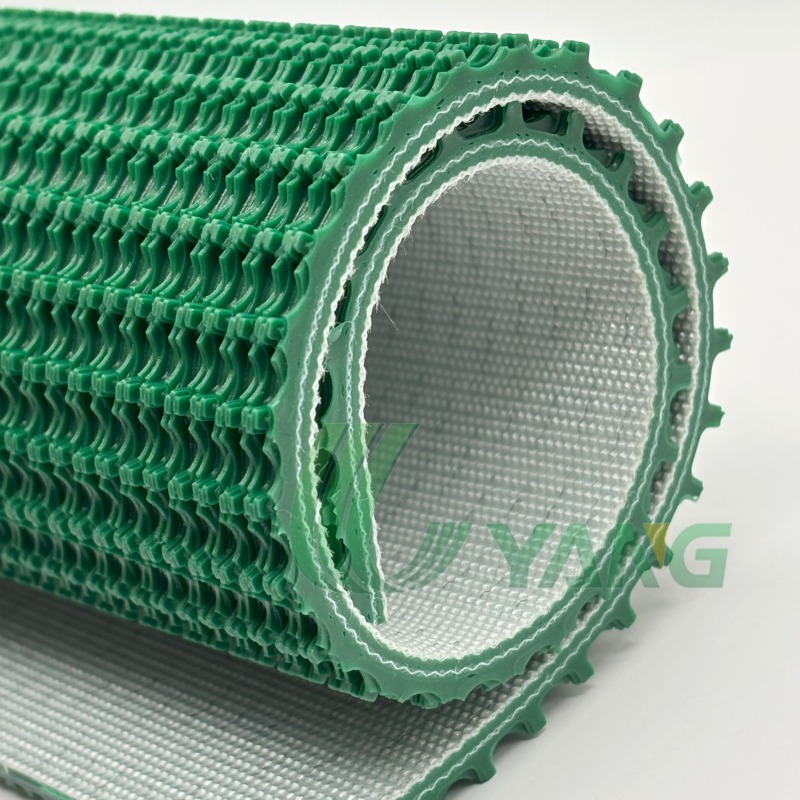

Rough Top pattern PVC conveyor belts, also known as light grass pattern belts, feature a subtle textured surface that provides moderate grip while maintaining smooth running performance. This pattern is widely used in light-duty conveying systems where stable product transfer and wear resistance are required.

Rough Top pattern PVC conveyor belts, also known as light grass pattern belts, feature a subtle textured surface that provides moderate grip while maintaining smooth running performance. This pattern is widely used in light-duty conveying systems where stable product transfer and wear resistance are required.

Moderate Grip – Prevents product slipping while ensuring smooth conveying.

Versatility – Applicable to many industries, including logistics, packaging, food, and electronics.

耐久性 – Resistant to wear and tear, extending belt lifespan.

Aesthetic & Practical – Fine textured surface improves appearance and reduces visible wear marks.

| Industry | Application Examples | Advantages |

|---|---|---|

| ロジスティクスと倉庫 | Sorting lines, parcel conveyors, and distribution centers | Stable conveying prevents product slipping |

| Food Processing & Packaging | Bakery, fruit & vegetable packaging, general food handling | Food-grade options available, easy to clean |

| Printing & Packaging | Carton transfer, paper conveying, and packaging lines | Smooth running, low noise |

| Electronics Industry | Component transfer, assembly lines | Anti-static options, precise conveying |

| Tobacco & Daily Goods | Cigarette transport, cosmetic packaging | Clean surface, hygienic appearance |

| Woodworking & Light Industry | Panel transfer, light manufacturing products | Wear-resistant, reliable operation |

Q1: What is a roughtop (light grass) pattern PVC conveyor belt?

A: It is a type of lightweight PVC belt with a subtle textured surface. The pattern provides moderate grip, making it suitable for stable product conveying in various industries such as logistics, food, packaging, and electronics.

Q2: In which industries is this belt commonly used?

A: It is widely used in logistics & parcel handling, food processing & packaging, printing, electronics, tobacco, cosmetics, and light manufacturing industries.

Q3: What thicknesses are available?

A: Standard thickness ranges from 4.0 mm to 7.0 mm, but customized thickness and specifications are available upon request.

Q4: Can the belt be used in the food industry?

A: Yes. Food-grade white or blue versions are available for food processing and packaging applications.

Q5: Is the surface easy to clean?

A: Yes. The fine fabric texture is designed for smooth running and can be easily cleaned, making it suitable for industries with hygiene requirements.

Q6: Do you provide customized sizes and colors?

A: Yes. We offer customization in width, length, thickness, and colors (green, blue, white, petrol, etc.) to match different application needs.

Q7: What are the main advantages compared to smooth belts?

A: The rough top pattern provides better grip, reduces product slippage, and offers a professional appearance while maintaining smooth operation.

信頼できる配送スケジュールと倉庫サポート。

全体的な価値を最大化するための競争力のある価格。

すべての市場セグメントに対応するための多様なオプション。

あらゆる種類の商品で柔軟なMOQサポート。

製品のパーソナライズされたロゴのカスタマイズ

すべての製品の使用およびインストールプロセスにオンライン技術サポートを提供する

すべての問い合わせと質問に対する迅速な最初の回答

高品質の画像、ビデオを提供して、販売収益を強化します

最速で15日以内に効率的な生産と船舶。

一般的には10〜15日ですが、ピークシーズンの場合、預金を受け取るのは約15〜20日間のサファーターになります

1.確認された仕様:厚さ、色、プリー、特徴、産業。

2。送信サンプル:Check.またはカスタマイズされたベルトの場合はサンプルを送信します。

3.注文の確認:サンプルが確認された後の販売契約に署名します。

4。デポジット:大量生産前の30%の預金。

5。配置された生産:生産を処理します。

6.残りの支払い:検査後、出荷前のバランス。

7。配送:目的地港に商品を出荷します。

8。{{url_placeholder_0}} invoice {{url_placeholder_1}} list {{url_placeholder_2}}} vioice {{url_placeholder_1}} listを確認します。