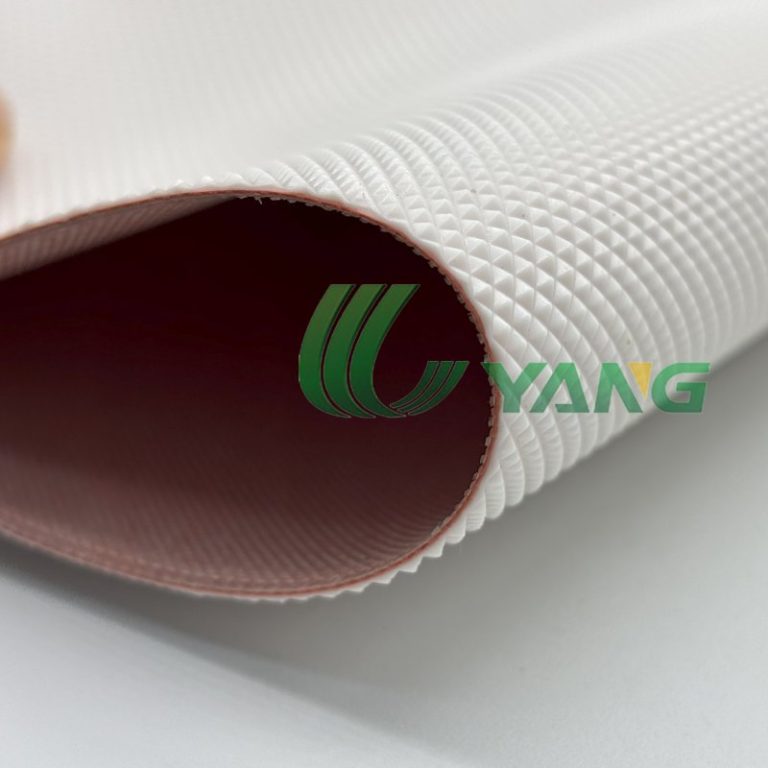

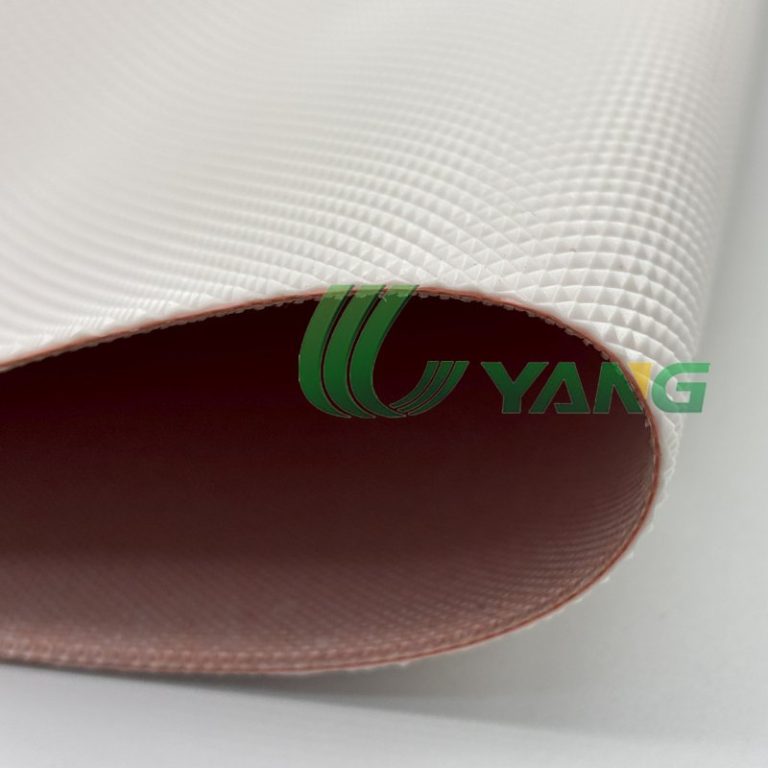

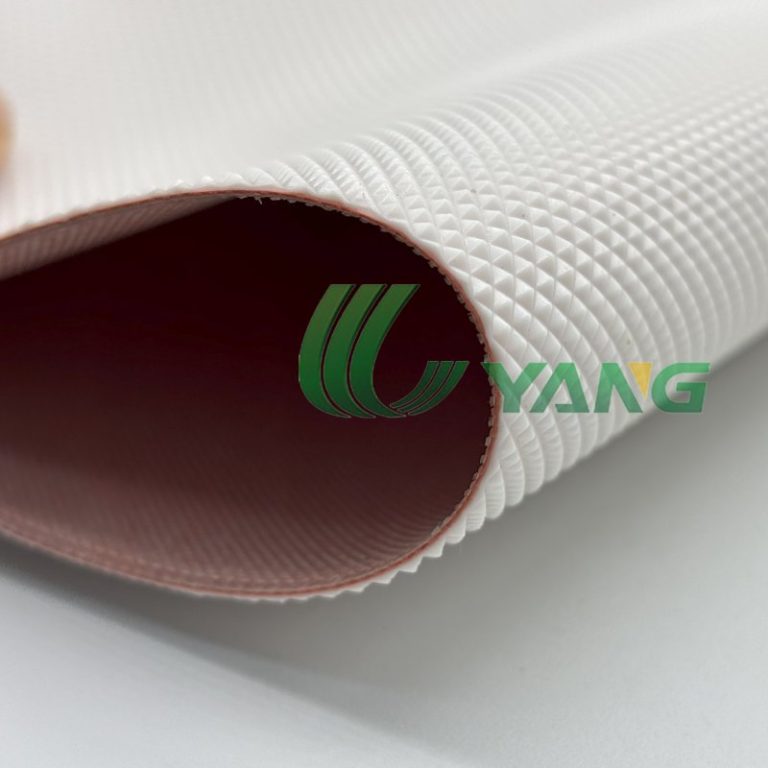

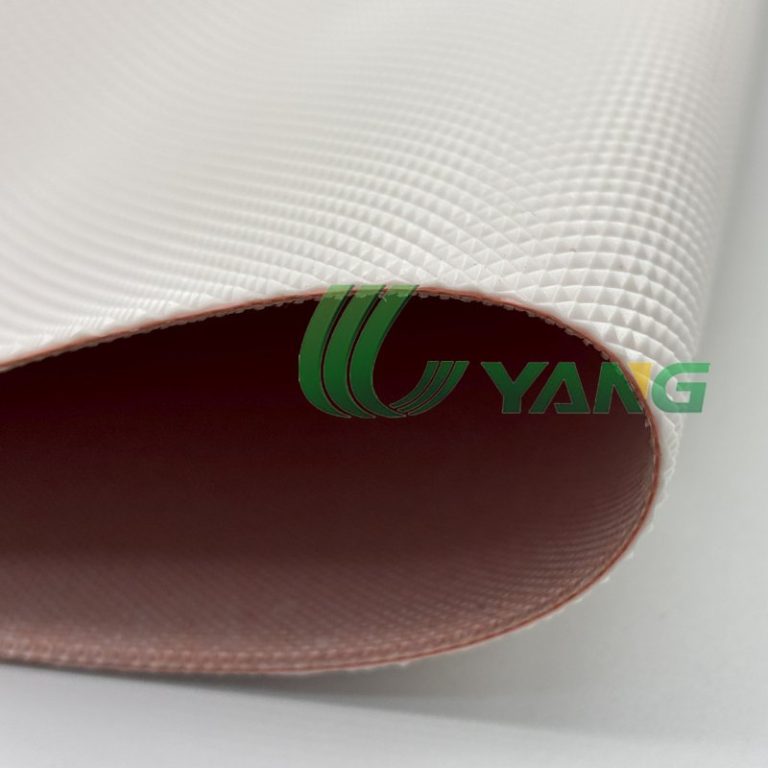

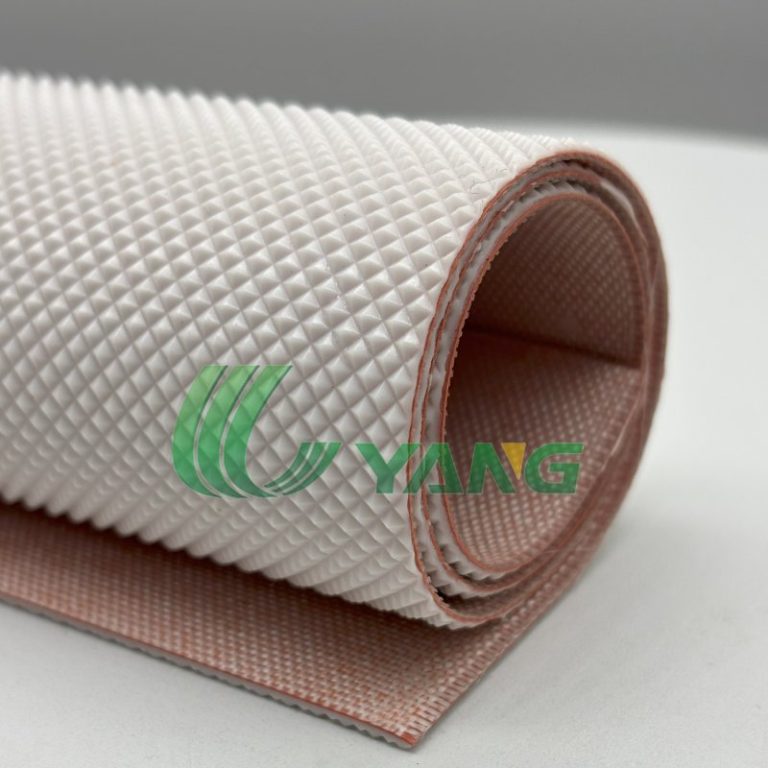

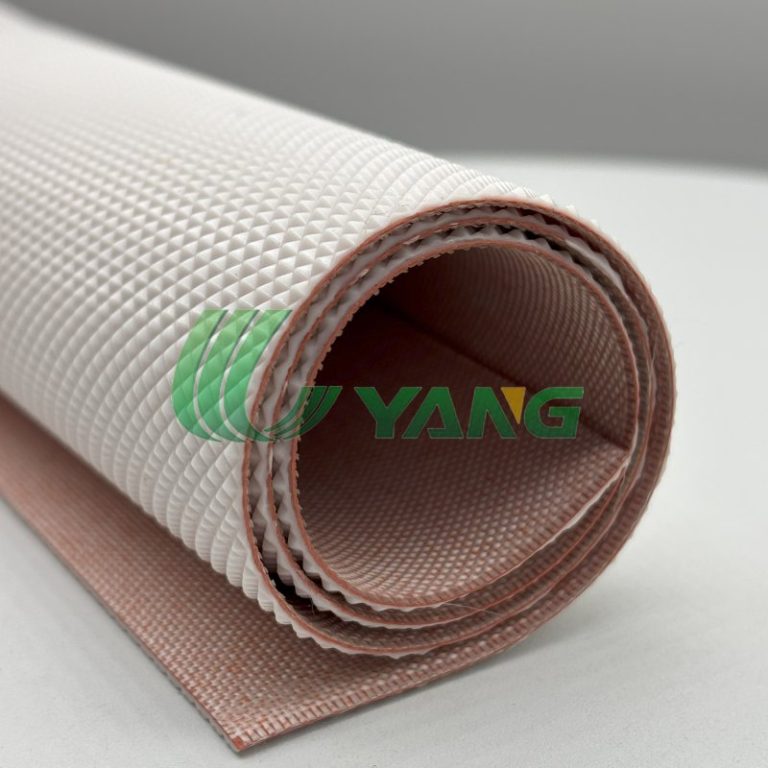

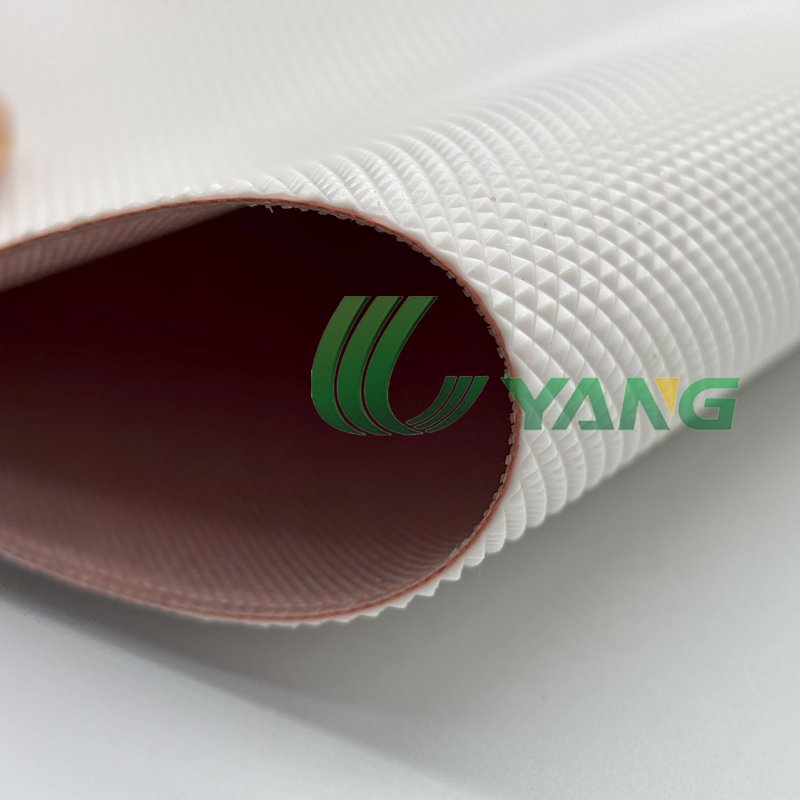

UYANG BELTING diamond-pattern silicone molds are precision-made tools used during hot-press or vulcanizing splices of diamond-top PVC and PU belts. They transfer the original diamond texture into the splice joint, delivering consistent grip, appearance, and performance across the whole belt.

UYANG BELTING diamond-pattern silicone molds are precision-made tools used during hot-press or vulcanizing splices of diamond-top PVC and PU belts. They transfer the original diamond texture into the splice joint, delivering consistent grip, appearance, and performance across the whole belt.

重要な利点:

Preserves Diamond Texture – keeps the original anti-slip pattern intact at the splice.

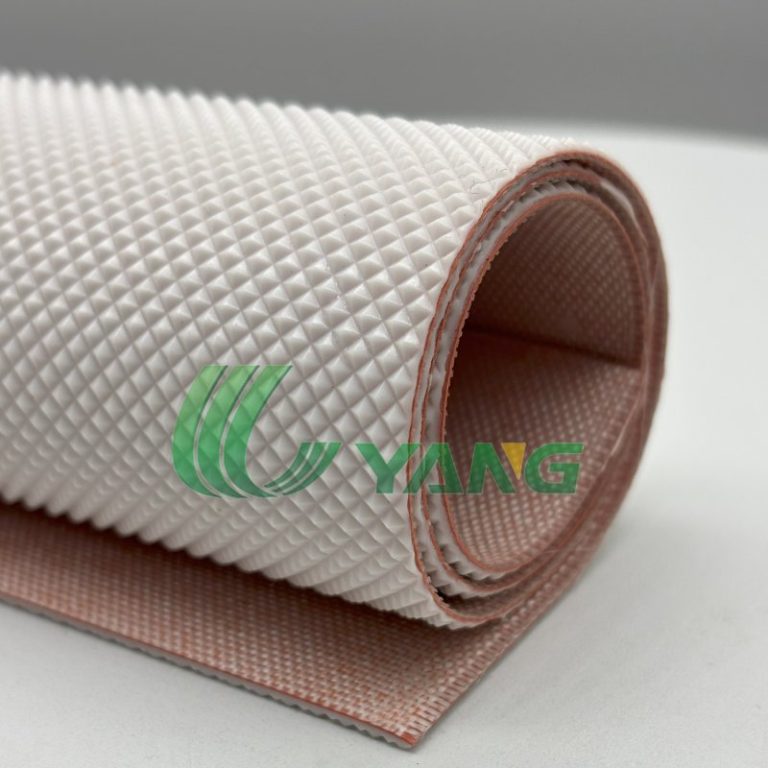

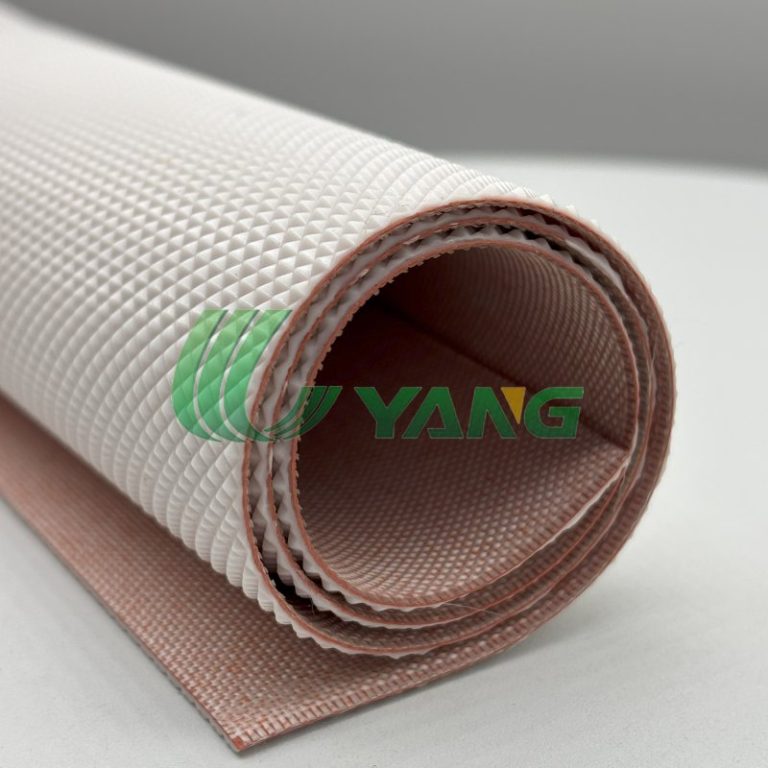

Durable & Heat-Resistant – high-quality silicone withstands repeated hot-press use.

Professional Finish – ensures smooth, uniform joints for better grip and appearance.

Diamond Silicone Mold- For Jointing Diamond PVC PU Belt-UYANG BELTING

Key benefits

Texture continuity — reproduces the diamond pattern at the splice so there’s no change in grip or product handling.

Professional finish — creates smooth, low-profile joints that match the rest of the belt visually and functionally.

Durable & heat-resistant — made from high-quality silicone that withstands typical splicing temperatures and repeated use.

Typical specifications & options

Material: high-temperature silicone (food-grade options on request)

Pattern: standard diamond pitch and depth (custom patterns available)

Sizes: standard sheets or custom cut to match belt width and splice length

Thickness: engineered to give correct pattern transfer under standard press settings

Compatibility: designed for PVC and PU conveyor belts with diamond (anti-slip) top surfaces

How it’s used (quick steps)

Prepare and clean belt ends; trim to even edges.

Place splice film (if used) and align belt ends in the hot-press.

Position the diamond silicone mold over the splice area with the patterned side facing the belt surface.

Apply heat and pressure per the belt manufacturer’s splicing parameters (temperature/time/pressure).

Allow the joint to cool; remove the mold and inspect the pattern transfer.

Trim and finish edges as needed, then test under load.

アプリケーション

Splicing diamond-top PVC/PU belts for food, packaging, logistics and light industry lines.

On-site repairs and factory splices where consistent grip and visual uniformity are required.

Color/zone matched lines where appearance and hygiene are critical.

Why choose our silicone molds

Precision pattern transfer, robust heat resistance, and custom sizing make our molds the professional choice for maintaining belt performance and a uniform look across splices. They save rework, reduce product slippage at joints, and help maintain cleanable, hygienic surfaces.

信頼できる配送スケジュールと倉庫サポート。

全体的な価値を最大化するための競争力のある価格。

すべての市場セグメントに対応するための多様なオプション。

あらゆる種類の商品で柔軟なMOQサポート。

製品のパーソナライズされたロゴのカスタマイズ

すべての製品の使用およびインストールプロセスにオンライン技術サポートを提供する

すべての問い合わせと質問に対する迅速な最初の回答

高品質の画像、ビデオを提供して、販売収益を強化します

最速で15日以内に効率的な生産と船舶。

一般的には10〜15日ですが、ピークシーズンの場合、預金を受け取るのは約15〜20日間のサファーターになります

1.確認された仕様:厚さ、色、プリー、特徴、産業。

2。送信サンプル:Check.またはカスタマイズされたベルトの場合はサンプルを送信します。

3.注文の確認:サンプルが確認された後の販売契約に署名します。

4。デポジット:大量生産前の30%の預金。

5。配置された生産:生産を処理します。

6.残りの支払い:検査後、出荷前のバランス。

7。配送:目的地港に商品を出荷します。

8。{{url_placeholder_0}} invoice {{url_placeholder_1}} list {{url_placeholder_2}}} vioice {{url_placeholder_1}} listを確認します。