Conveyor belts are essential for modern ski resorts, ensuring safe and efficient transportation for skiers while withstanding harsh winter conditions. Choosing the right belt involves balancing safety, durability, and performance, especially in icy environments. This guide explores key considerations for selecting conveyor belts, from slip-resistant materials to compliance with industry standards. Discover how uyangベルト’s advanced solutions enhance ski resort operations while improving visitor experience through reliable, low-maintenance designs. Whether optimizing slope accessibility or reducing wait times, the right conveyor system can transform your resort’s efficiency and safety.

Key Considerations for Selecting a Conveyor Belt for Ski Resorts

Why Are Safety and Durability Crucial in Ski Resort Conveyor Belts?

When it comes to ski resorts, conveyor belts play a pivotal role in ensuring the smooth transportation of skiers and snowboarders, especially beginners. Safety is paramount as these belts often operate in icy and slippery conditions. A high-quality belt must feature a slip-resistant surface to prevent accidents. Durability is equally important since these systems face extreme weather conditions, including heavy snowfall and freezing temperatures. Frequent breakdowns not only disrupt operations but also increase maintenance costs.

What Factors Influence Conveyor Belt Performance in Cold Conditions?

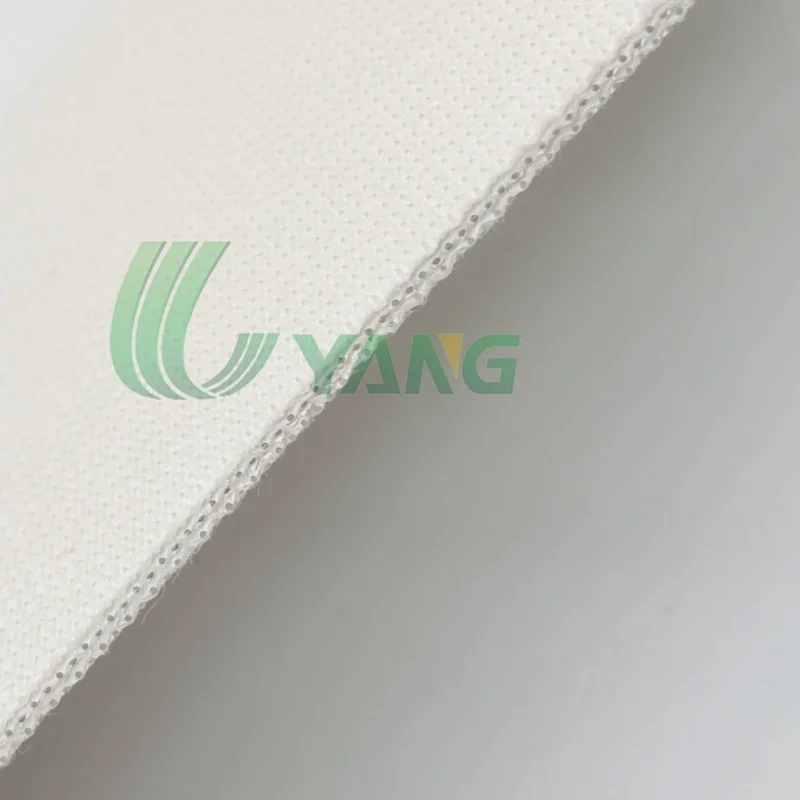

The performance of a conveyor belt in ski resorts largely depends on its material composition and structural design. Materials like rubber or polyurethane are preferred due to their flexibility and resistance to low temperatures. Additionally, the belt must be designed to handle snow accumulation without losing traction or efficiency. Anti-slip technology ensures that passengers remain secure even during rapid transitions.

How Important Is Compliance with Industry Standards?

Adhering to industry standards is non-negotiable for ski resort conveyor belts. Certifications such as ISO 9001:2015 ensure that the product meets stringent quality benchmarks. Moreover, compliance with safety regulations like ATEX (explosion-proof) or EN/ISO 340 (fire-resistant) guarantees the system’s reliability under challenging conditions. Meeting these standards minimizes legal risks while enhancing operational safety.

Features of a High-Quality Ski Resort Conveyor Belt

What Makes Slip-Resistant Surfaces Essential?

Slip-resistant surfaces are critical for passenger safety, especially in ski resorts where snow and ice are prevalent. These surfaces reduce the risk of falls, providing a secure footing for skiers as they ascend slopes. Advanced materials like polyurethane can enhance grip while maintaining durability.

How Can Conveyor Belts Withstand Extreme Weather?

Materials engineered for cold resistance, such as thermoplastic elastomers (TPE) or specialized rubber compounds, are ideal for extreme weather conditions. These materials retain their flexibility and strength even at sub-zero temperatures, ensuring uninterrupted operation.

Why Is Easy Maintenance Important?

Maintenance plays a significant role in the longevity of conveyor belt systems. A low-maintenance design reduces downtime and operational costs while ensuring consistent performance. Features like modular components allow for quick repairs without dismantling the entire system.

Can Energy Efficiency Be Achieved Without Compromising Performance?

Energy-efficient conveyor belts not only reduce operational costs but also align with environmental sustainability goals. Systems designed with optimized motors and lightweight materials consume less energy while maintaining high performance.

Uyang Belting: A Trusted Solution for Ski Resort Conveyor Belts

What Sets Uyang Belting Apart in Conveyor Belt Manufacturing?

Uyang Belting stands out as a global leader with over 20 years of expertise in manufacturing high-quality conveyor belts tailored to diverse industries, including ski resorts. With a production facility spanning 80,000 square meters and 15 advanced production lines, they ensure strict quality control and innovative solutions. Their commitment to excellence is evident through certifications like ISO 9001:2015 and compliance with international safety standards.

How Do Uyang Belting Products Address Ski Resort Needs?

Cold-Resistant Materials Designed for Harsh Environments

Uyang Belting offers products made from cold-resistant materials like TPE and specialized rubber compounds. These materials maintain flexibility and durability even under extreme cold.

Anti-Slip Technology for Enhanced Passenger Safety

Their belts feature advanced anti-slip technology, ensuring maximum safety on icy surfaces. This innovation significantly reduces accident risks.

Customizable Lengths and Widths to Suit Various Slopes

Customization options allow ski resorts to tailor belt dimensions according to specific slope requirements. This flexibility ensures optimal functionality across different terrains.

Low-Maintenance Design to Reduce Downtime

The low-maintenance design minimizes disruptions by simplifying repairs. Modular components enable quick replacements without halting operations.

Recommendations for Implementing Uyang Belting Products in Ski Resorts

How Can You Assess the Specific Needs of Your Ski Resort?

Identifying the unique requirements of your ski resort is crucial before implementing conveyor belt systems. Factors such as terrain, slope gradient, expected foot traffic, and weather conditions should be carefully evaluated. For example, steeper slopes may require belts with enhanced traction and durability, while areas with high snowfall demand materials resistant to freezing temperatures. Additionally, considering the demographic of visitors—whether families, beginners, or advanced skiers—can guide you in selecting belts with specific safety features like slip-resistant surfaces.

What Are the Steps to Install and Maintain Conveyor Belt Systems Effectively?

Proper installation and maintenance are vital for maximizing the efficiency and lifespan of conveyor belt systems. Begin by ensuring that the foundation is stable and aligned with slope angles. Choose belts constructed from cold-resistant materials like thermoplastic elastomers (TPE) or specialized rubber compounds that retain flexibility under sub-zero temperatures . Regular inspections should follow installation to identify wear and tear early. Maintenance schedules must include cleaning snow accumulation from belts and lubricating mechanical parts to avoid operational disruptions.

How Do Regular Inspections Ensure Long-Term Safety and Reliability?

Routine inspections are indispensable for maintaining both safety and operational reliability. Check for signs of wear on belt surfaces, especially in high-traffic areas. Inspect tension levels to prevent slippage or misalignment during operation. Advanced monitoring technologies can also be employed to detect anomalies in real-time, minimizing downtime . By addressing minor issues promptly, you can significantly extend the life of your conveyor system while ensuring uninterrupted service.

The Role of Conveyor Belts in Enhancing Visitor Experience at Ski Resorts

How Do Conveyor Belts Improve Accessibility for Beginners and Families?

Conveyor belts make skiing more accessible by simplifying uphill transportation for beginners and families. These systems eliminate the need for physical exertion when climbing slopes, allowing visitors to focus on enjoying their experience. The inclusion of slip-resistant surfaces ensures a secure footing for all users, reducing anxiety among first-time skiers . This user-friendly approach encourages more people to participate in skiing activities.

Can Efficient Belt Systems Reduce Wait Times?

Efficiently designed conveyor belt systems significantly reduce wait times by streamlining the flow of visitors ascending slopes. Flat belts are particularly effective due to their adaptability with different load capacities . By optimizing speed settings based on real-time demand, these systems prevent bottlenecks during peak hours, enhancing overall visitor satisfaction.

How Do Conveyor Belts Promote a Safe and Enjoyable Environment?

Safety is a cornerstone of any ski resort experience. Conveyor belts equipped with anti-slip technology provide a stable surface even under icy conditions . Additionally, using materials certified for fire resistance and explosion-proof standards ensures compliance with stringent safety regulations . These features collectively create a secure environment where visitors can enjoy their time without concerns about potential hazards.

For ski resorts seeking reliable solutions tailored to their unique needs, uyangベルト offers advanced conveyor belt systems designed specifically for challenging environments. With over 20 years of expertise and ISO-certified quality control processes., they ensure products that enhance efficiency while prioritizing safety.

よくあるご質問

Q1: What is the most suitable material for ski resort conveyor belts?

A: Materials like thermoplastic elastomers (TPE) or specialized rubber compounds are ideal due to their cold resistance and durability.

Q2: How often should ski resort conveyor belts be inspected?

A: Regular inspections should be conducted weekly during peak season to identify wear or mechanical issues promptly.

Q3: Are there customizable options available for slope-specific requirements?

A: Yes, many manufacturers offer customizable lengths and widths to match specific slope gradients and visitor capacities.