Running a tire plant is not for the faint of heart. The pressure is constant: raw rubber mixes need to move without delay, green tires can’t lose shape on the line, and the curing stage demands absolute precision. In all of these steps, conveyor belts carry the weight—literally. When the belts fail, the whole line stalls. And as you know, downtime is costly.

That’s why the question of which conveyor belt types best serve tire manufacturing isn’t just theory. It’s a practical matter of efficiency, safety, and long-term cost.

Before diving into specific belt choices, let’s pause for a moment. Behind many of the solutions in this space, you’ll find Uyang Belting. The company has spent years refining belts for demanding industries like tire production. Instead of one-size-fits-all, they design belts that fit each stage: mixing, transport, curing, inspection. You get belts built for friction resistance, durability under heat, and reliability in heavy-duty work. Choosing them feels less like a purchase and more like adding an extra technician to your team—quietly keeping the line moving shift after shift.

What Are the Key Conveyor Belt Options for Tire Manufacturing?

In tire plants, three belt types stand out. Each addresses a different challenge on the line.

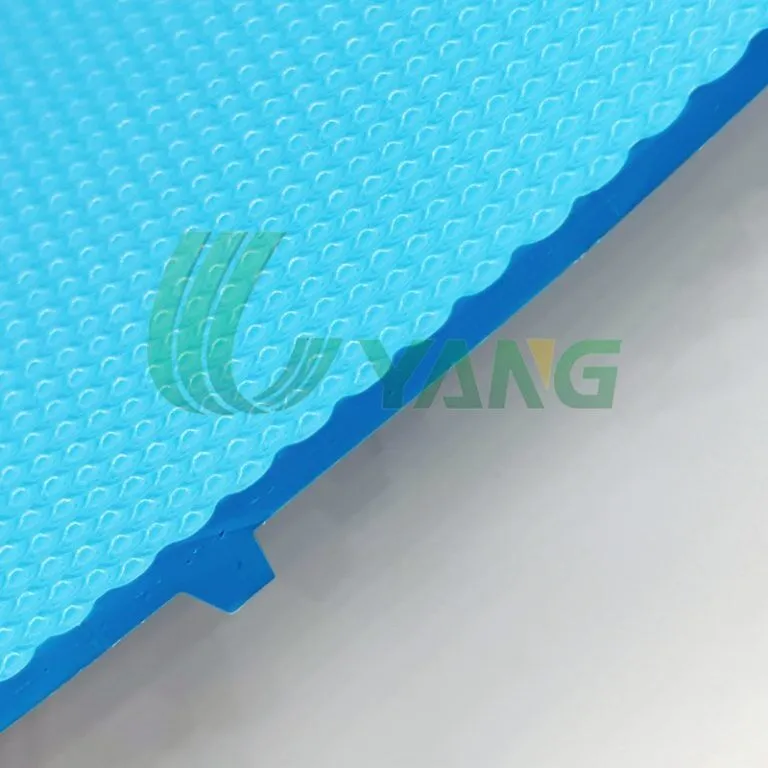

PVC Conveyor Belt with Polyester Woven Cotton Top

This design combines a PVC layer with a cotton top. Why does that matter? The cotton gives friction, so heavy green tires don’t slip. The PVC base keeps costs controlled while resisting wear from continuous runs. If you walk into a mixing hall or an assembly line, chances are you’ll spot a belt like this. For factories that value stable grip and predictable performance, the PVC Conveyor Belt with Polyester Woven Cotton Top is a dependable choice.

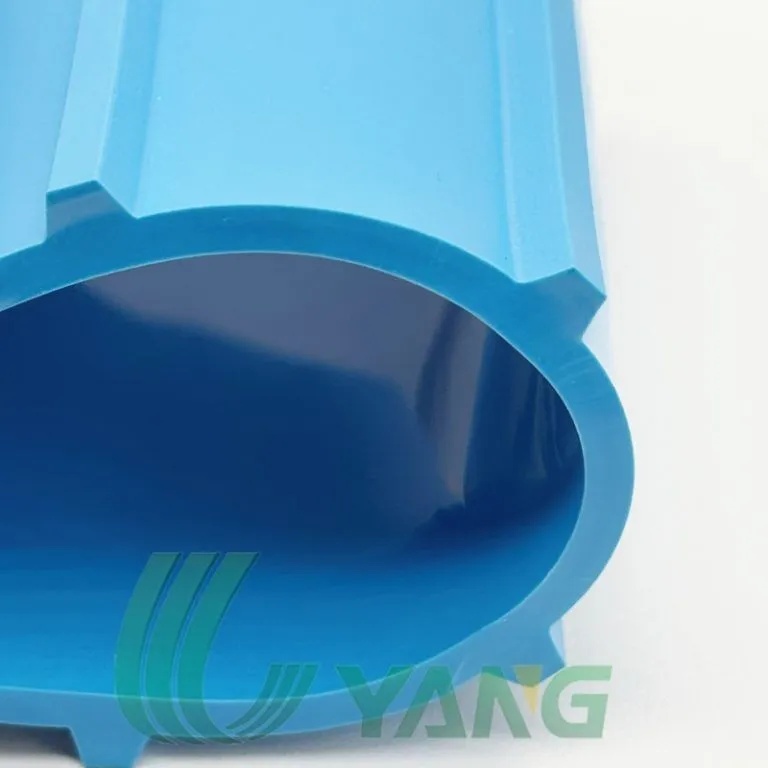

Cotton Canvas PU Belt 2.5mm

Sometimes you don’t need maximum thickness; you need agility. A 2.5mm cotton canvas PU belt works well in mid-weight applications, such as moving semi-processed rubber compounds or feeding assembly stages. The canvas base keeps the belt steady, while the PU layer handles friction and resists minor cuts. Operators like it because it feels lighter to manage yet holds up better than cheap synthetic belts.

Cotton Canvas PU Belt 3.0mm

Then there are the heavy stages: curing and final inspection. Belts in these zones need extra muscle. A 3.0mm canvas PU conveyor belt offers that. It doesn’t buckle under the weight of finished tires, and it stays dimensionally stable when the environment gets hot. Factories running three shifts often report that thicker PU belts cut replacement frequency almost in half. That means fewer weekend maintenance calls—something any plant manager can appreciate.

How Do Conveyor Belts Improve Efficiency in Tire Plants?

It might sound obvious, but efficiency is more than speed. In tire plants, efficiency means moving material without damaging it and without pausing production.

Reduced Downtime and Maintenance Needs

When belts last longer, you don’t have to schedule emergency stops. A worn-out belt can snap mid-shift and shut down a whole curing line. With better construction, you stretch out the maintenance window, sometimes by months.

Smooth Material Flow for Green Tire Handling

Green tires are fragile. If a belt surface is uneven or slippery, they deform. That one small change can lead to defects later. Smooth, cotton-based tops keep tires stable, protecting shape before they reach the press.

Better Durability in Harsh Production Environments

Tire plants aren’t gentle places. Heat, dust, and constant vibration are the norm. Belts built with PU coatings and cotton canvas cores take this punishment better than standard PVC-only designs. Over the long haul, that resilience turns into cost savings.

Why Is Material Selection Critical in Tire Conveyor Belts?

Every belt is a compromise. The art is choosing the right materials for the right job.

Polyester Cotton Top Layer for Heat and Friction Resistance

The cotton layer grips rubber compounds. This is crucial in early stages when material is sticky and heavy. Polyester blends add a little more toughness against wear. UYANG BELTING offers belts with cotton-polyester tops that are widely used in tire mixing halls, providing the right balance between grip and durability.

PU Coating for Flexibility and Longevity

PU layers act like armor. They bend without cracking, they resist oils from rubber, and they extend belt life. A small investment in PU often pays off quickly through reduced replacement cycles. In fact, UYANG’s 2.5mm and 3.0mm cotton canvas PU conveyor belts are designed specifically for tire plants that need longer belt cycles and less downtime.

PVC Core for Stability and Cost Efficiency

PVC is still the workhorse of the industry. It offers stability and keeps the price manageable. That’s why many plants combine PVC cores with cotton or PU tops—they get both economy and performance. The PVC Conveyor Belt with Polyester Woven Cotton Top from UYANG is a typical example, balancing cost-effectiveness with the strength needed in tire production.

What Applications Require Specialized Conveyor Belts in Tire Production?

Not all belts belong everywhere. Each stage demands something slightly different.

Mixing and Calendering Stages

These early steps involve sticky rubber, carbon black, and chemicals. Belts here need chemical resistance and easy cleaning. UYANG’s PVC belts are often used here because of their smooth tops and easy maintenance.

Green Tire Transport and Assembly Sections

This is where shape matters most. Belts must carry unfinished tires without distortion. Grip and surface stability are key. Cotton-top belts from UYANG give operators more control during this fragile stage.

Curing and Final Inspection Lines

Heat and weight dominate here. Belts must resist deformation while carrying heavy loads repeatedly. A thicker PU-coated canvas belt from UYANG performs well in this environment, keeping lines running longer without premature failures.

Which Belt Features Deliver Cost Savings Over Time?

Let’s talk money. Conveyor belts are often seen as a cost center, but the right features flip the equation.

Longer Service Life with Canvas and PU Layers

If a belt lasts twice as long, you’re not just saving on belt cost—you’re avoiding downtime and labor expenses from replacements. Plants using UYANG’s canvas PU belts often report extended service intervals compared to generic alternatives.

Lower Energy Use from Lightweight Construction

Lighter belts put less strain on motors. Over a year, the reduced energy use can add up to thousands in savings for a large plant. UYANG’s tire belts are engineered with this balance in mind—strong enough for the job but not unnecessarily heavy.

Easy Maintenance for Reduced Labor Costs

Smooth, well-joined belts clean faster. If your crew spends 20 minutes instead of an hour washing down a belt, that’s real labor saved week after week. UYANG supplies belts with reliable splicing and easy-clean surfaces that simplify maintenance routines.

How Can You Choose the Right Partner for Tire Belt Solutions?

The belts matter, but so does the supplier. A reliable partner can be the difference between smooth production and constant breakdowns.

Customized Options for Tire Plant Needs

Every plant is different. Some need extra thickness for curing lines, others need coatings that resist oil or heat. A good partner offers both. UYANG BELTING has built its reputation on tailoring belts for specific stages of tire production—whether that’s a PVC cotton-top belt for mixing halls or a cotton canvas PU belt for curing presses. Instead of pushing a one-size-fits-all solution, they work with you to match belt properties to the challenges you face daily.

Compliance with International Quality Standards

When belts are certified for FDA, EU, or other global standards, you avoid surprises during audits. It’s not just food plants that face strict checks—tire factories also go through safety reviews, and failing one can be costly. UYANG BELTING develops belts that align with these requirements, giving you a layer of assurance that your equipment won’t be the weak point in compliance.

Global Supply and Service Support

Production doesn’t wait for late shipments. Having a supplier with international reach means belts arrive when you need them. UYANG BELTING exports worldwide, backed by technical service teams that help with installation and after-sales support. If something goes wrong mid-shift, you know help is available instead of waiting weeks for a replacement. For plants running three shifts, that kind of responsiveness is not a luxury—it’s survival.

FAQs

Q1: How often should conveyor belts in a tire plant be replaced?

A: It depends on the stage. Mixing belts wear faster, sometimes within 12–18 months, while PU-coated curing belts can last several years under proper maintenance.

Q2: Are thicker belts always better for heavy-duty use?

A: Not always. Thicker belts add strength, but they also increase weight and energy use. Choosing the right balance of thickness and material is more effective.

Q3: Can one belt type cover both mixing and curing stages?

A: Usually no. Mixing demands chemical resistance, while curing demands heat resistance. Using the same belt type across both stages often shortens service life.