The dairy industry needs super strict cleanliness, reliability, and smooth operations to give customers fresh, safe, and awesome products. A big part of hitting these goals is picking the right conveyor belt for production lines. Seamless homogeneous belts, sometimes called easy-to-clean belts, are super popular in dairy processing because of their cool benefits. This article dives into why seamless homogeneous belts from Celting uyang are a game-changer for dairy processing. It covers their perks in keeping things clean, staying tough, working efficiently, and following safety rules.

Seamless Homogeneous Belts for Safer Dairy Production

Why Cleanliness Matters in Dairy Processing

Dairy production has some of the strictest hygiene rules in the food world. Germs like bacteria or mold can lead to pricey recalls. Even worse, they can make people sick. So, keeping equipment spotless during dairy production and packaging is a must. Seamless homogeneous belts from Uyang Belting are an awesome fix for this. They’re designed to stop contamination and make cleaning a breeze.

What Are Seamless Homogeneous Belts?

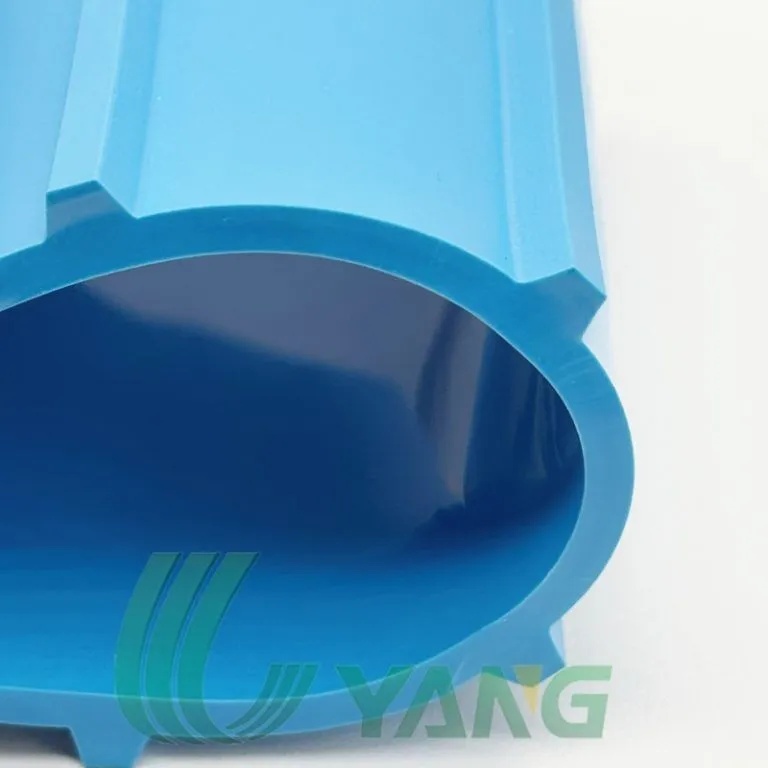

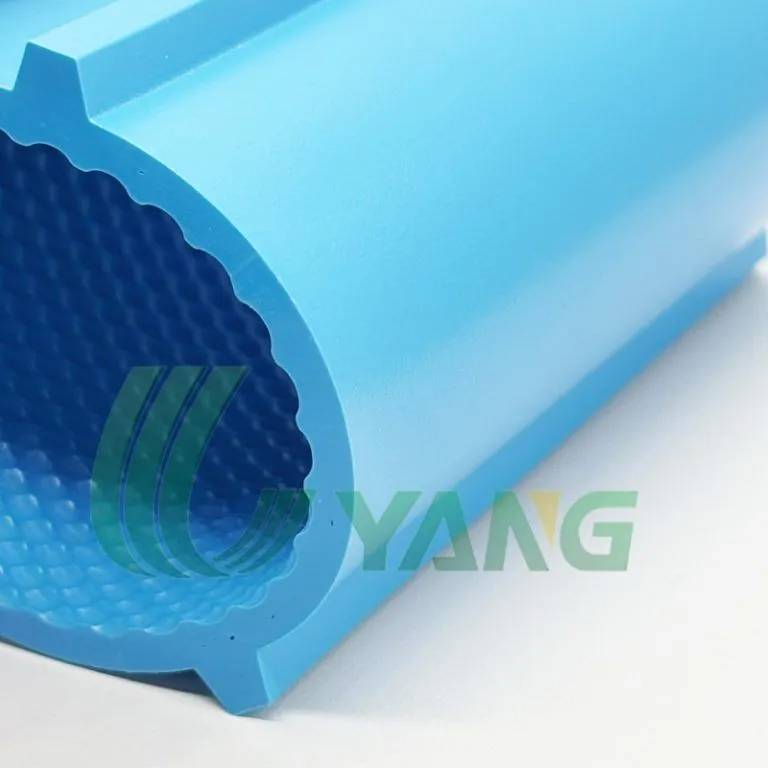

Seamless homogeneous belts are made from one solid material, usually thermoplastic polyurethane (TPU). This stuff is great at resisting oil, water, and germs. Unlike old-school belts with fabric layers or stitches, Uyang Belting’s seamless belts have no gaps or seams. That makes them super easy to clean. They’re perfect for places like dairy plants, where hygiene is everything.

Key Benefits of Seamless Homogeneous Belts in Dairy Processing

In dairy processing, hygiene is non-negotiable. Uyang Belting’s seamless homogeneous belts deliver unmatched cleanliness, durability, and compliance—ensuring safer products and smoother operations.

Awesome Cleanliness Standards

Smooth, Non-Porous Surface

One huge perk of Uyang Belting’s seamless homogeneous belts is their sleek, non-porous surface. Regular belts often have fabric layers or seams that trap dirt, germs, or liquids. But seamless belts? They’re totally smooth and even. No tiny spots for bacteria to hide out. This keeps the production line way cleaner.

Keeps Germs at Bay

The seamless design of Uyang Belting’s belts stops bacteria from building up. This is super important in dairy processing. Products like milk, cheese, and butter can get contaminated easily. Plus, TPU has germ-fighting powers that make these belts even safer. They keep the production line clean and trustworthy for dairy work.

Super Tough and Efficient

Stands Up to Wear and Tear

Uyang Belting’s seamless homogeneous belts are built to handle rough industrial settings. Their strong design fights off cuts, scratches, and wear, even in busy dairy plants. Old belts break down when they get wet or oily. Not these ones—they stay solid for longer. That means fewer replacements, less downtime, and more savings.

Holds Up in Tough Conditions

Another cool thing? These belts work great in extreme environments. Dairy processing deals with hot pasteurization, steamy humidity, or freezing cold refrigeration units. Uyang Belting’s seamless belts don’t warp or fail in these conditions. They keep the production line running smoothly, no matter what. That’s a big deal for dairy plants.

Facile à nettoyer et à entretenir

Perfect for CIP Systems

Uyang Belting’s seamless homogeneous belts are made to work with Clean-In-Place (CIP) systems. These systems clean equipment without taking it apart, which is common in food processing. The belts’ smooth, non-absorbent surface is ideal for CIP cleaning. It cuts down on manual scrubbing and makes cleaning faster and better.

Less Downtime, Lower Costs

Cleaning these seamless belts is quick and simple. That means dairy plants spend less time on maintenance. Regular belts need long, hands-on cleaning, which stops production and costs more for labor. With Uyang Belting’s seamless homogeneous belts, cleaning is a snap. This reduces downtime and saves money, keeping the production line humming.

Following Food Safety Rules

Meets FDA and EU Standards

Uyang Belting’s seamless homogeneous belts pass tough food safety tests, like FDA, EU, and USDA standards. This makes them safe for touching dairy products directly. In the dairy world, keeping harmful germs out is a top priority. These belts help make that happen.

Fights Germs Naturally

The TPU in Uyang Belting’s belts has built-in germ-fighting features. Paired with the seamless design, this keeps the belts clean and safe for their whole lifespan. These features stop bacteria and fungi from growing. That helps keep dairy products safe and high-quality.

Where These Belts Shine in Dairy Processing

Uyang Belting’s seamless homogeneous belts are used in tons of dairy production steps, from raw milk handling to packaging finished goods.

Cheese Production

In cheese making, these belts move curds, whey, and finished cheese. Their smooth surface stops bits from sticking, which lowers the chance of contamination. They also handle the high fat content in cheese, which can wreck other belts over time. This makes them a solid pick for cheese production.

Yogurt and Milk Processing

Uyang Belting’s seamless homogeneous belts are awesome for yogurt production lines. They take care of tasks like filling, labeling, and packaging. Their resistance to moisture and dairy proteins keeps them clean and working well the whole time. This ensures everything runs smoothly.

Butter and Cream Handling

Butter and cream are fatty, so the conveyor belt needs to resist oil buildup and stay clean. Uyang Belting’s seamless belts are perfect for this. They stop residue from sticking and are easy to clean. This keeps hygiene standards high in butter and cream production.

Things to Think About When Picking a Seamless Homogeneous Belt

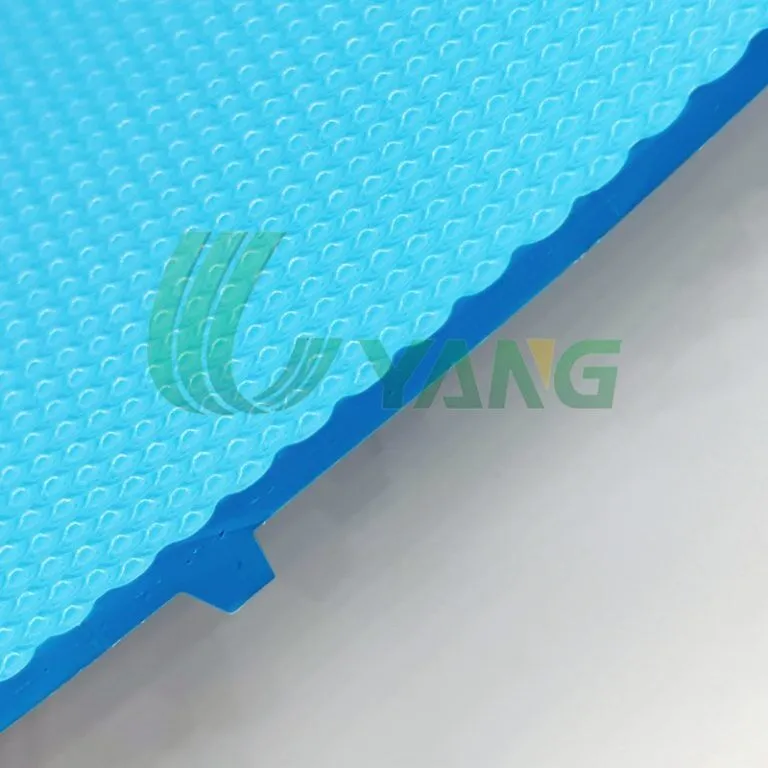

Belt Thickness and Texture

The belt’s thickness should fit the dairy job. For heavy stuff like cheese handling, go for a thicker belt (3-4mm). For lighter tasks like yogurt processing, a thinner belt (2mm) is fine. You can also tweak the surface texture for better grip or easier cleaning, depending on what you need.

Options de personnalisation (Color, Edge Sealing)

Lots of dairy plants pick blue belts from Uyang Belting. The color makes it easy to spot dirt or germs. You can also add sealed edges to block liquids, which boosts hygiene and toughness. These custom options help match specific dairy needs.

Conclusion

Uyang Belting’s seamless homogeneous belts are changing the dairy industry for the better. They offer top-notch cleanliness, toughness, and efficiency. Their smooth, seamless design is perfect for places where hygiene is critical. They resist germs, are easy to clean, and meet safety rules. That makes them the best choice for dairy producers who want to improve productivity and keep standards high.

Choosing seamless homogeneous belts from Uyang Belting isn’t just about following rules. It’s a smart way to keep operations running smoothly and set up for long-term success in dairy processing.

FAQs

Q1: How often do I need to replace seamless homogeneous belts in dairy processing?

A1: Uyang Belting’s seamless homogeneous belts are made to last. They don’t need replacing as often as regular belts. How long they last depends on how much you use them, but their toughness makes them super durable.

Q2: Can seamless homogeneous belts work in other food industries besides dairy?

A2: Totally! Uyang Belting’s seamless homogeneous belts are great for other food industries like meat, seafood, bakery, and even pharmaceuticals. Their clean and sturdy design fits any industry with tough hygiene needs.

Q3: What’s the best way to clean seamless homogeneous belts?

A3: Uyang Belting’s seamless belts work awesome with Clean-In-Place (CIP) systems. This makes cleaning easy without taking anything apart. Use food-safe, pH-neutral cleaners regularly. For a deeper clean, try steam or chlorine-based solutions weekly to keep things super hygienic