| Artículo |

Value / Options |

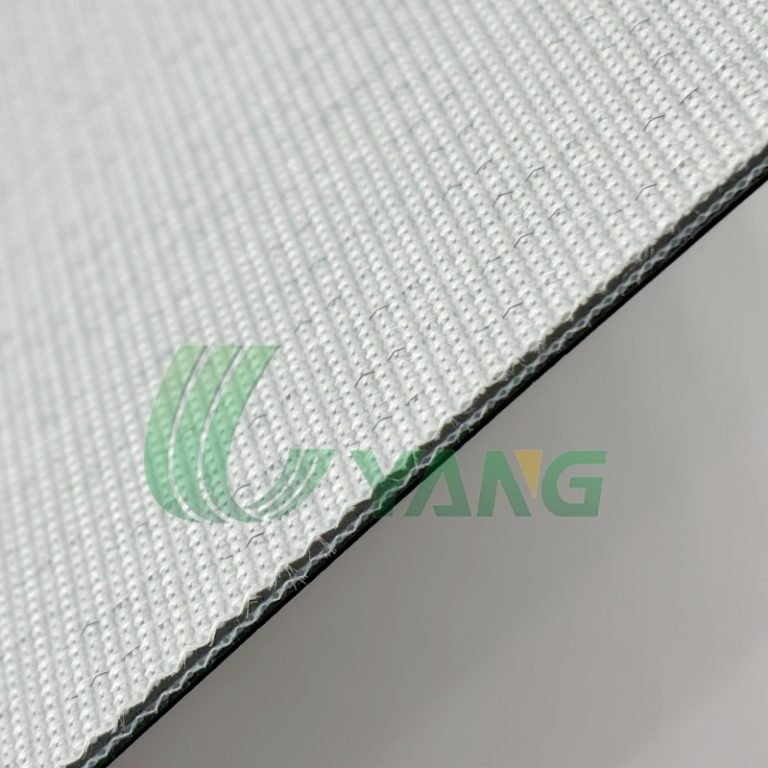

| Espesor |

2.0 mm / 3.0 mm |

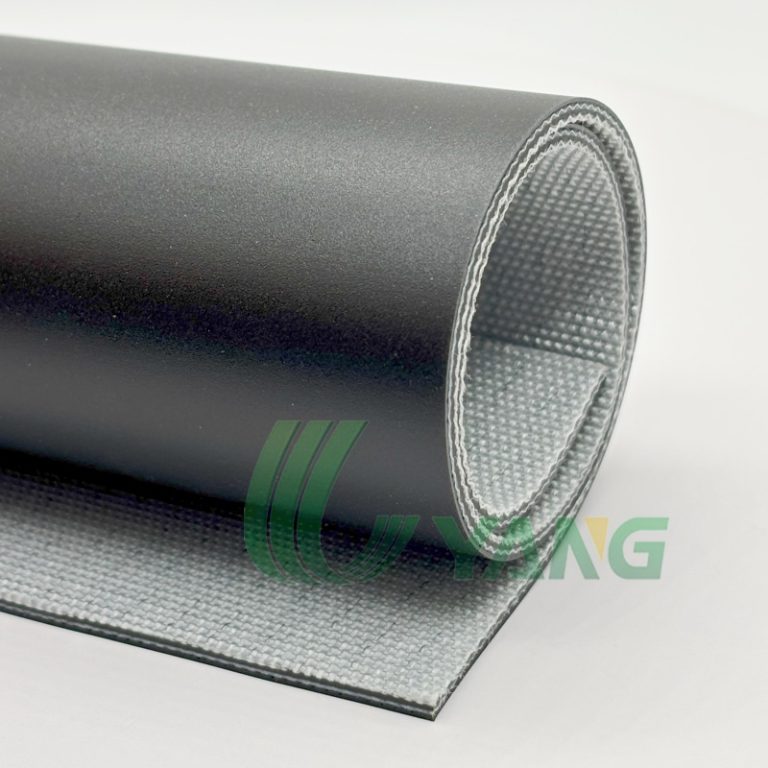

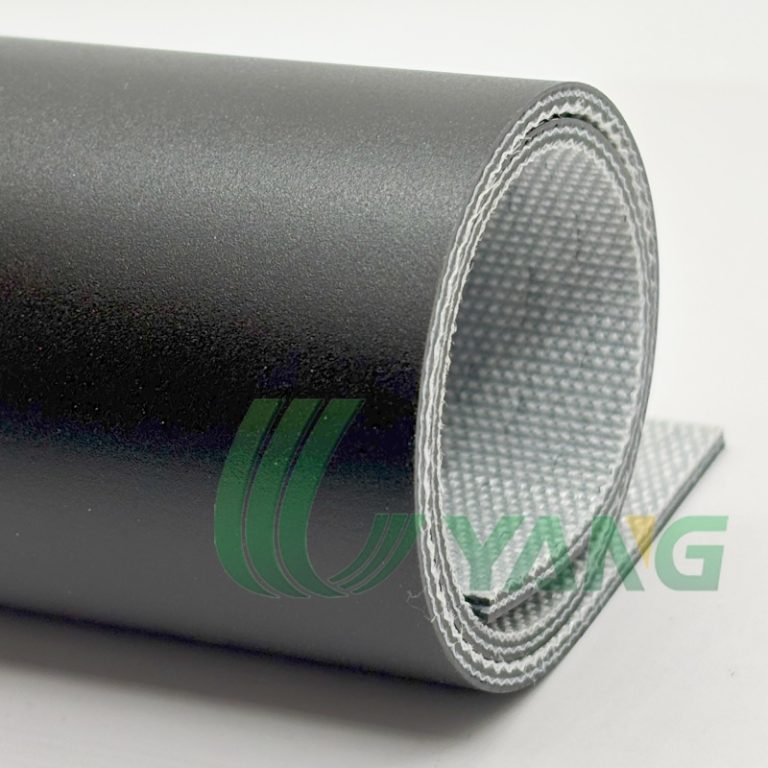

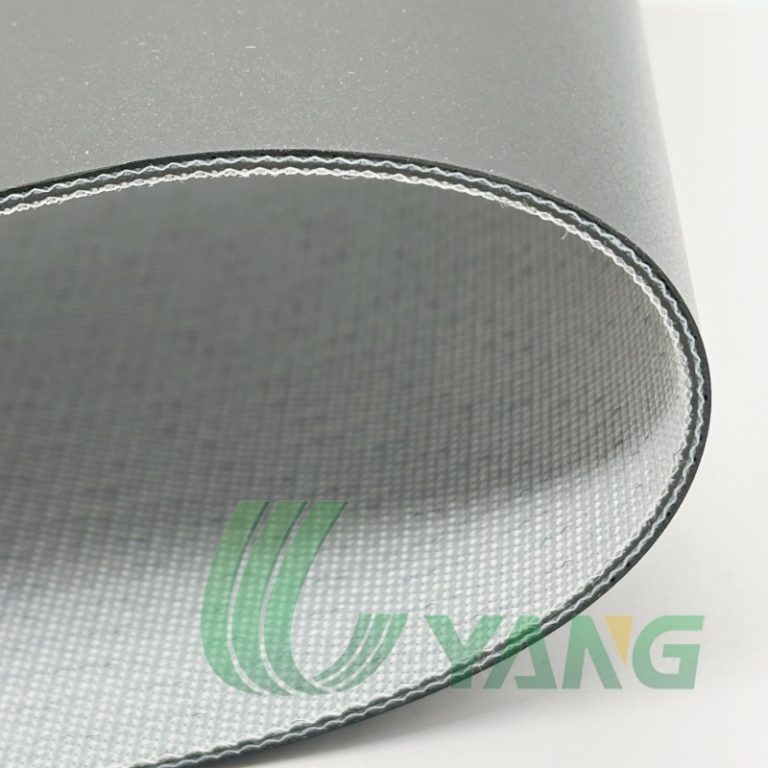

| Top Cover |

PVC, Antistatic Surface; |

| Acabado de superficie |

Black Matte |

| Bottom Layer |

Low-noise Fabric Backing |

| Width Range |

100 mm – 3400 mm (customizable) |

| Longitud |

Supplied by roll or cut to size or endless ; |

| Rango de temperatura |

-20°C to +80°C |

| Joint Options |

Hot splicing / Mechanical fastener |

| Solicitud |

Supermarket & Bank & Retail Checkout Counters |

Aplicaciones típicas

Payment, Shipping & Delivery Terms

- Payment: 30% T/T deposit, 70% balance prior to shipment. L/C at sight accepted.

- Lead Time: 10–20 business days after deposit for standard items; 20–25 business days for custom orders.

- Incoterms: EXW, FOB, CIF,DDP available on request.

- Warranty: 12 months against manufacturing defects. Claims must be reported within 14 days of receipt.

FAQ — Black Matte PVC Conveyor Belt for Supermarket Checkout Counter

Q1: What thicknesses are available?

A: Standard thicknesses are 2.0 mm y 3.0 mm. Other thicknesses (e.g., 1.5 mm, 2.5 mm, 4.0 mm) can be produced on request— don’t hesitate to get in touch with sales for availability.

Q2: Is the surface antistatic?

A: Yes — the top PVC layer receives antistatic treatment. Surface resistivity can be adjusted to meet specific ESD requirements (provide target Ω/□ range, and we can test).

Q3: What is the backing material? Does it reduce noise?

A: The bottom is a low-noise fabric backing designed to reduce running noise and provide stable support for light-load checkout use.

Q4: What widths and lengths can you supply?

A: Typical widths range from 100 mm to 3400 mm (custom widths available). Supplied by the meter on rolls or cut-to-length per order.

Q5: What joint/splice methods do you recommend?

A: For the smoothest appearance, we recommend hot splicing (heat weld). Mechanical fasteners (steel fasteners) are available when on-site equipment prevents hot splicing.

Q6: How do I clean and maintain the belt?

A: Clean with a soft cloth and neutral detergent; avoid strong acids/alkalis and sharp tools. Regularly inspect for debris on rollers and check splice areas for wear.

Q7: Is this belt suitable for high-speed or heavy-load applications?

A: This product is designed for checkout/light-load, low-to-moderate speed applications. For heavy loads or continuous high-speed conveying, request our recommended industrial belt options.

Q8: Can you print logos or lines on the belt?

A: Yes — logo printing, guide lines, or demarcation stripes can be added. Please provide artwork and confirm quantities for print setup.

Q9: What is the sample policy and lead time?

R: Sample lead time: typically 3–7 business days (depending on customization).

Production lead time: standard items 10–20 business days after deposit and sample approval; custom orders 20–35 business days.

Q10: What are payment and shipping terms?

A: Typical terms: 30% T/T deposit, 70% balance before shipment. We ship by sea, air, or courier. Incoterms commonly used: FOB (port of loading) by default; CIF/DDP available on request.

Q11: What warranty do you provide?

A: We offer a 12-month warranty against manufacturing defects under normal use. For claims, provide photos and notify us within the claim window (visible damage on delivery: within 7 days; hidden defects: within 14 days).

Q12: What is the minimum order quantity (MOQ)?

A: MOQ depends on specifications and customization. Small/sample orders are accepted but pricing may differ. Please contact sales with required width, thickness, length and quantity for a quote.

Q13: Are there any temperature or chemical limitations?

A: Typical working temperature range is -20°C a 80°C. Avoid prolonged exposure to strong solvents, concentrated acids or alkalis—consult us if your application involves chemicals.

Q14: Do you provide pre-shipment inspection and test reports?

A: Yes — pre-shipment inspection can be arranged. Surface resistivity, tensile, and other test reports can be provided upon request (may incur testing fees).

Q15: How do I get a quote or place an order?

A: Contact our sales team with your required thickness, width, length, quantity, and any customization (printing/ESD specs) — email: info.uyangbelting@tj-uyang.com or click Request a Quote on the contact page. We’ll reply with price, MOQ, lead time, and shipping options.

ES

ES