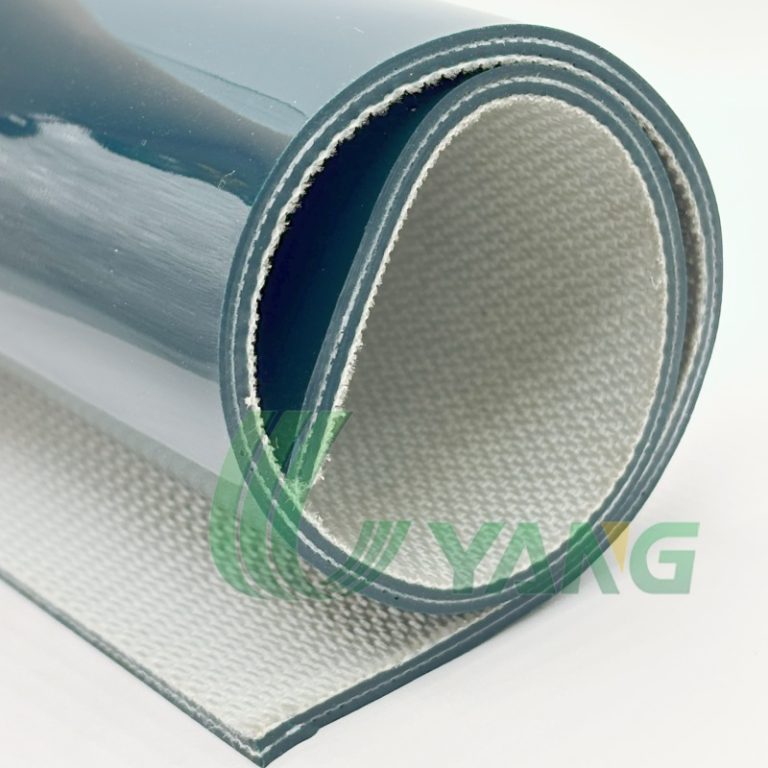

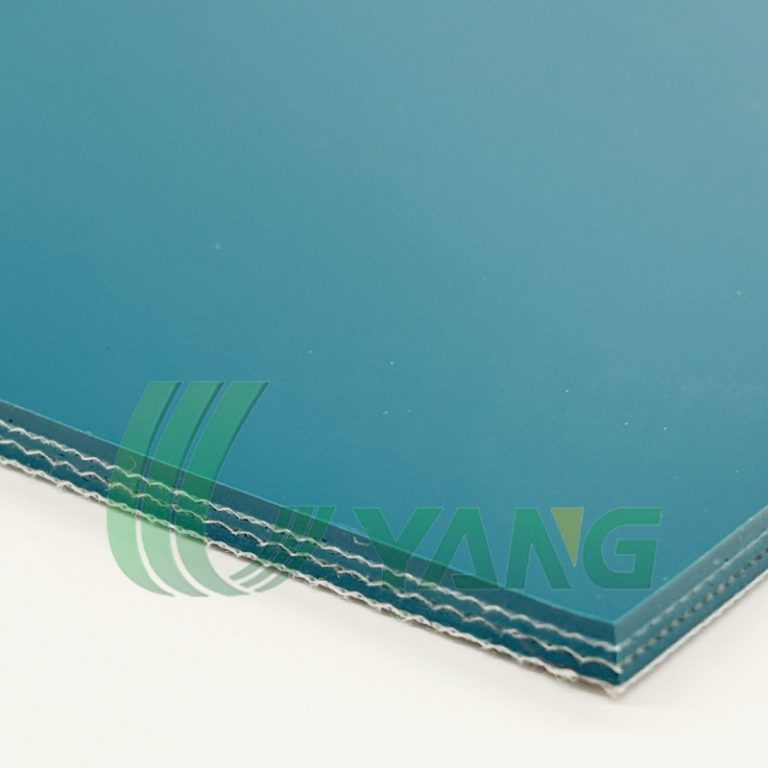

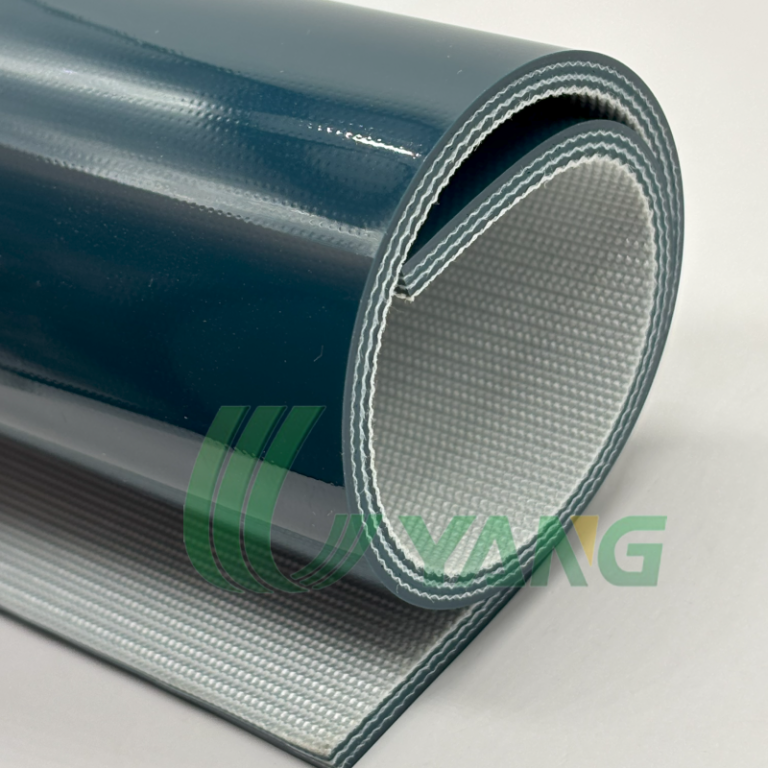

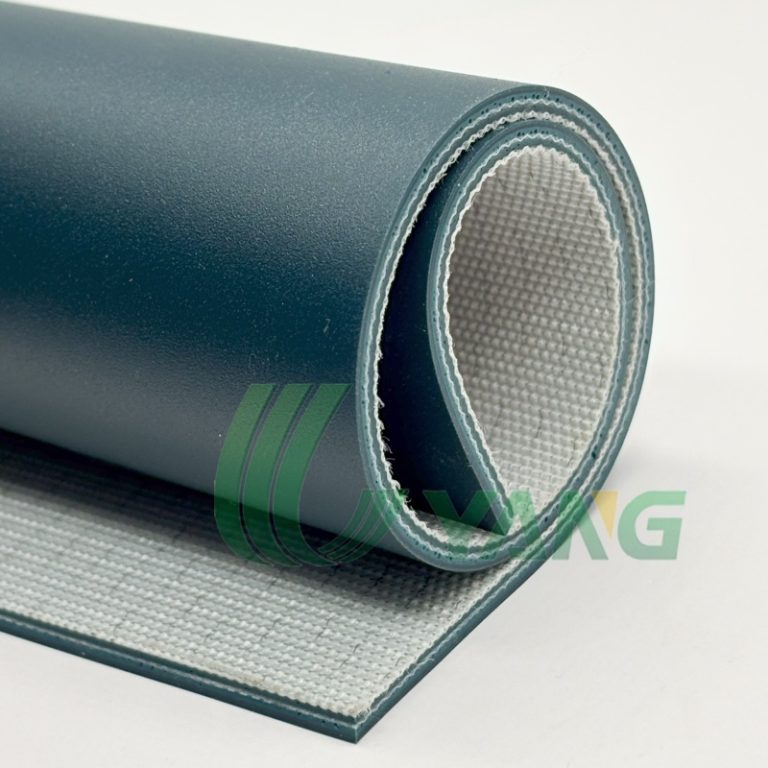

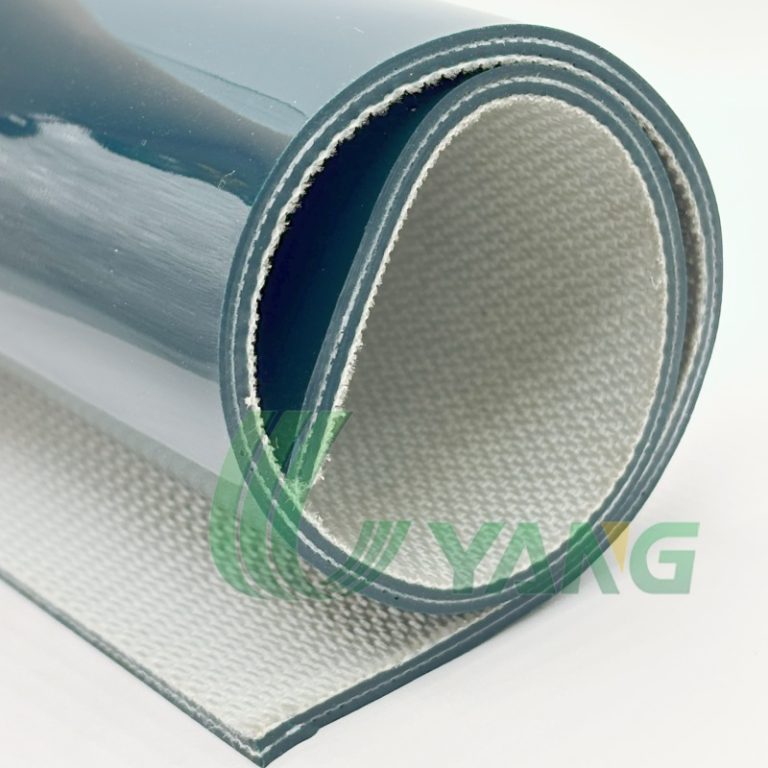

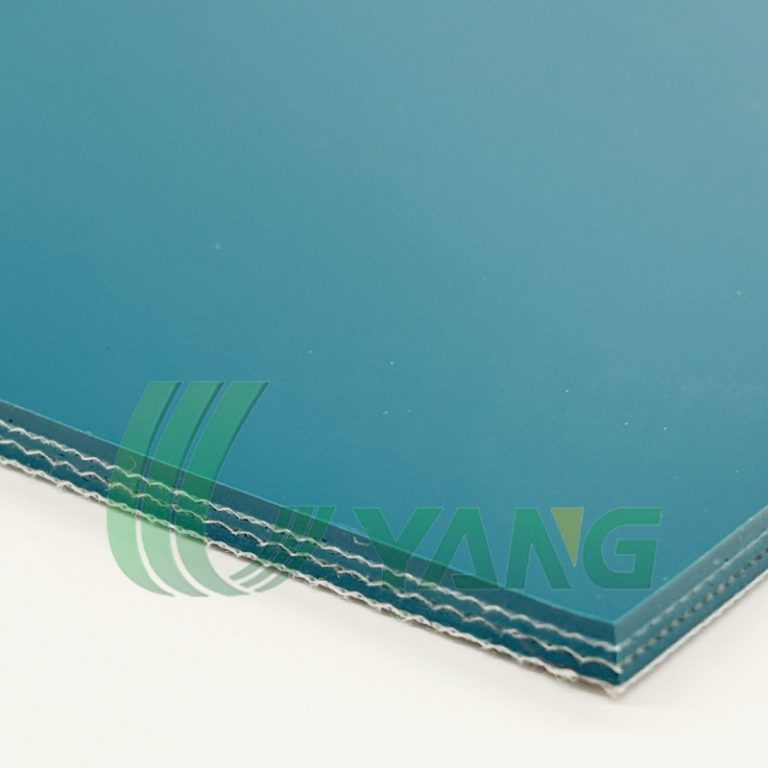

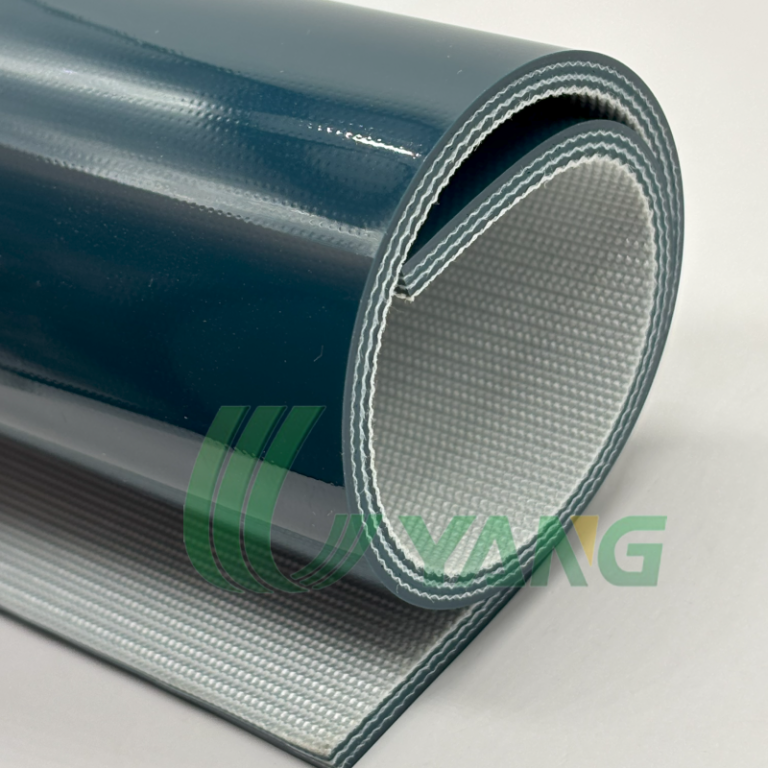

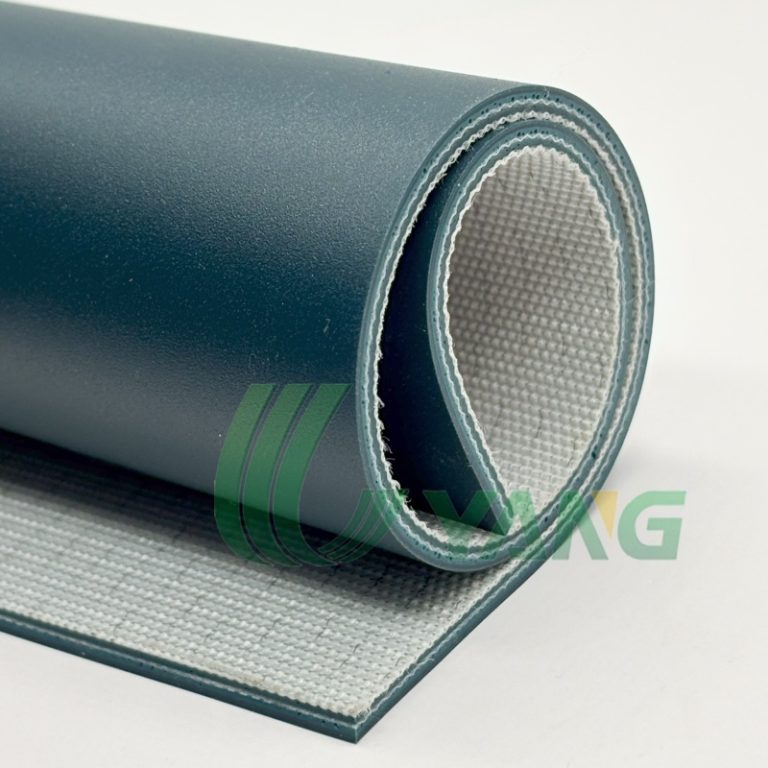

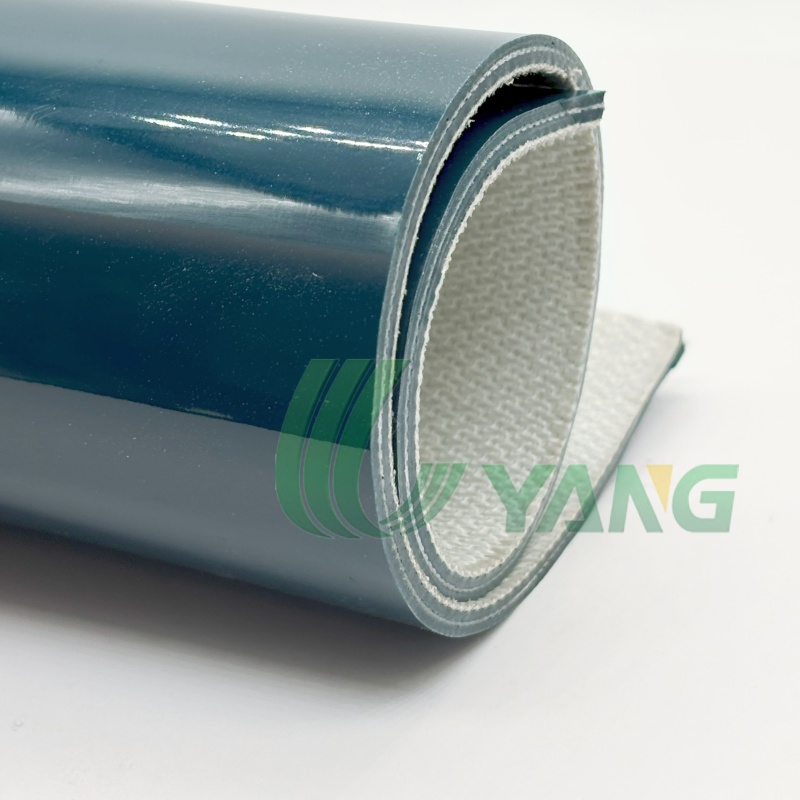

Petrol PVC conveyor belts are widely used in various light-duty conveying industries. The unique petrol shade provides better visual distinction from products and creates a clean, modern appearance in production environments.

Petrol PVC conveyor belts are widely used in various light-duty conveying industries. The unique petrol shade provides better visual distinction from products and creates a clean, modern appearance in production environments.

Vorteile:

Clear product contrast and easy identification

Professional and aesthetic appearance

Same durability, flexibility, and reliability as standard green or blue PVC belts

Logistics & Parcel Handling

Used in sorting lines and parcel transfer systems, where the petrol color helps operators clearly distinguish belts from goods.

Electronics Industry

Suitable for handling small electronic components and light assemblies. The softer petrol tone reduces visual fatigue for operators working long hours.

Printing & Packaging

Commonly applied in paper, carton, and packaging transfer lines. The color ensures easy product contrast and a neat appearance.

Automated Warehousing Systems

Petrol belts are often used in automated storage and retrieval systems to transport boxes, trays, and parcels.

Woodworking & Furniture Industry

Ideal for conveying wooden boards, panels, and furniture components. The belt’s durable surface resists wear and maintains a professional look.

General Industrial Conveying

Selected by many factories for visual management and standardized production environments.

| Industry | Anwendung | Recommended Thickness / Model |

| Lebensmittelindustrie | Bakery, fruit & vegetable processing, packaging | 1.5 – 3.0 mm, FDA/food-grade PVC |

| Logistik und Lagerung | Sorting lines, parcel conveyors, distribution hubs | 2.0 – 3.5 mm, anti-static PVC |

| Printing Industry | Paper conveying, carton handling, packaging lines | 1.5 – 2.5 mm, low-noise PVC |

| Ceramic Industry | Tile handling, polishing lines | 3.0 – 4.5 mm, wear-resistant PVC |

| Treadmill / Fitness | Running machines, fitness equipment | 1.6 – 2.2 mm, high-grip PVC |

| Woodworking / Furniture | Panel transfer, furniture assembly lines | 2.5 – 4.0 mm, abrasion-resistant |

| Electronics Industry | Component transfer, assembly lines | 1.5 – 2.5 mm, anti-static PVC |

| Tobacco Industry | Cigarette conveying, packaging | 2.0 – 3.0 mm, food-grade PVC |

| Automotive / Tire | Rubber parts transfer, tire handling | 3.5 – 5.0 mm, heavy-duty PVC |

| Gipsbranche | Board forming and processing lines | 3.0 – 4.5 mm, taper-edge PVC |

Zuverlässige Lieferpläne und Lagerunterstützung.

Wettbewerbspreise zur Maximierung des Gesamtwerts.

Verschiedene Optionen, um alle Marktsegmente gerecht zu werden.

Flexibler MOQ -Unterstützung mit allen Arten von Waren;

Personalisierte Logo -Anpassung an den Produkten

Bieten Sie den technischen Online -Support für alle Produktnutzungs- und Installationsprozesse

Schnelle erste Antwort auf alle Anfragen und Fragen

Stellen Sie Qualitätsbilder und Video zur Verfügung, um den Umsatzumsatz zu steigern

Effiziente Produktion und Schiff innerhalb von 15 Tagen am schnellsten.

Im Allgemeinen sind es 10-15 Tage, wenn die Hochsaison etwa 15 bis 20 Tage lang ist, erhält Safter die Kaution

1. Bestätigte Spezifikation: Dicke, Farbe, Lagen, Merkmale und Industrie;

2. Proben Senden: Wir senden Proben für Sie check.

3. Bestätigen Sie die Bestellung: Unterzeichnung des Verkaufsvertrags nach Bestätigung der Stichproben.

4. Kaution: 30% Einzahlung vor der Massenproduktion.

5. Produktion arrangiert: Wir werden die Produktion verarbeiten.

S.

7. Versand: Wir versenden die Waren an den Bestimmungshafen.

8. Bestätigen Sie die Belastungsrechnung {{url_placeholder_0}} Invoice {{url_placeholder_1}} list {{url_placeholder_2}} des Ursprungs;