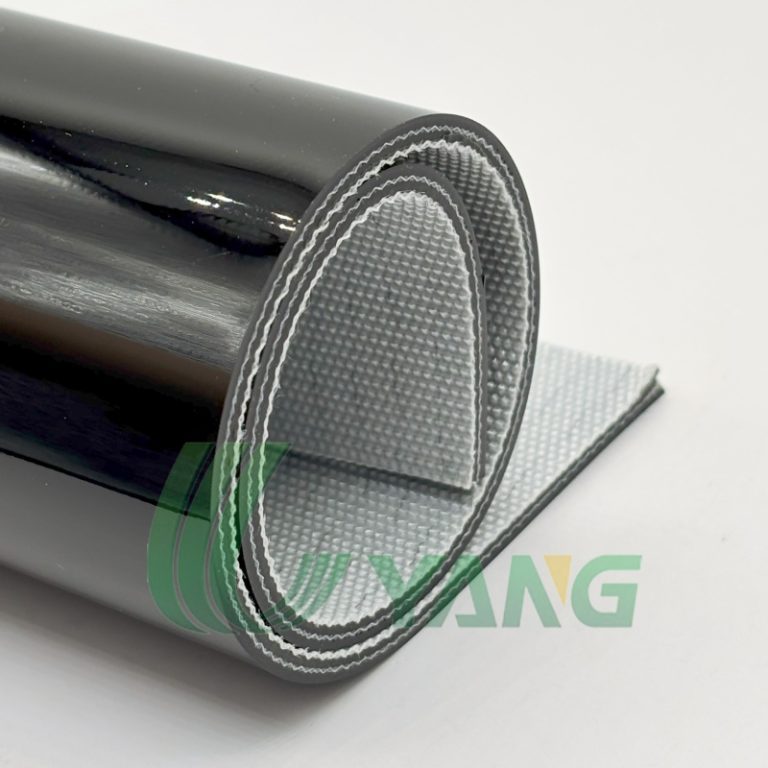

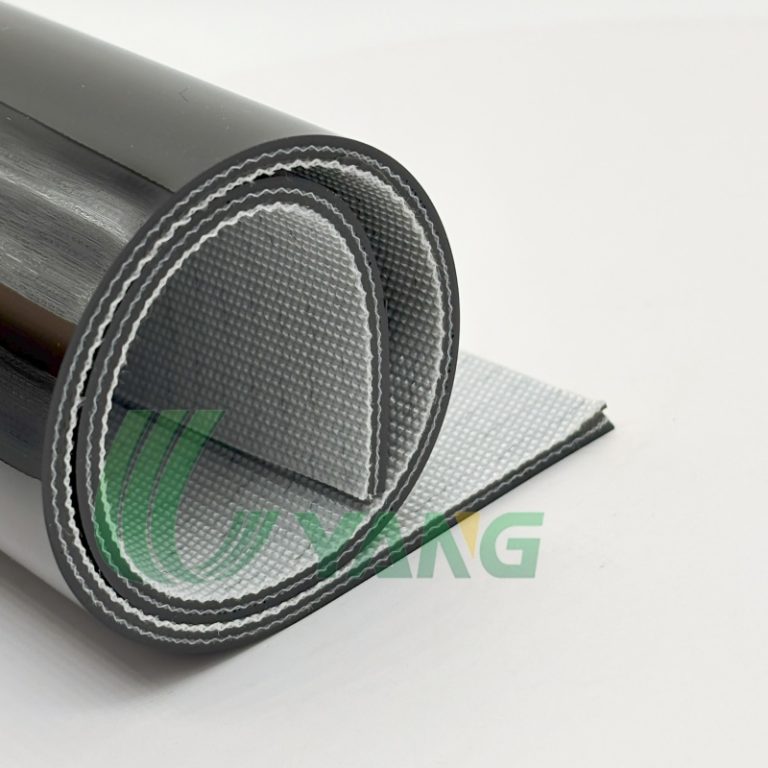

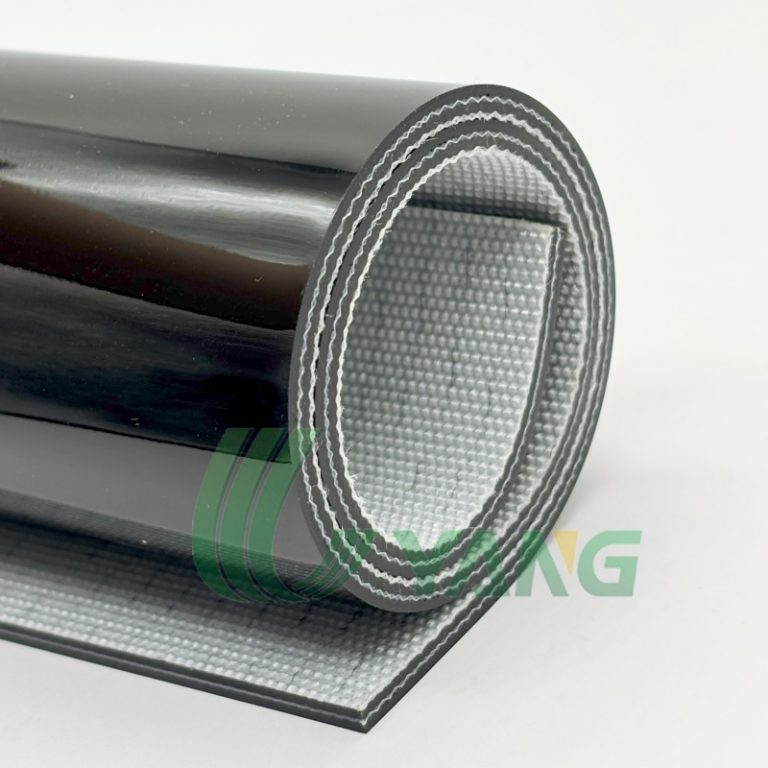

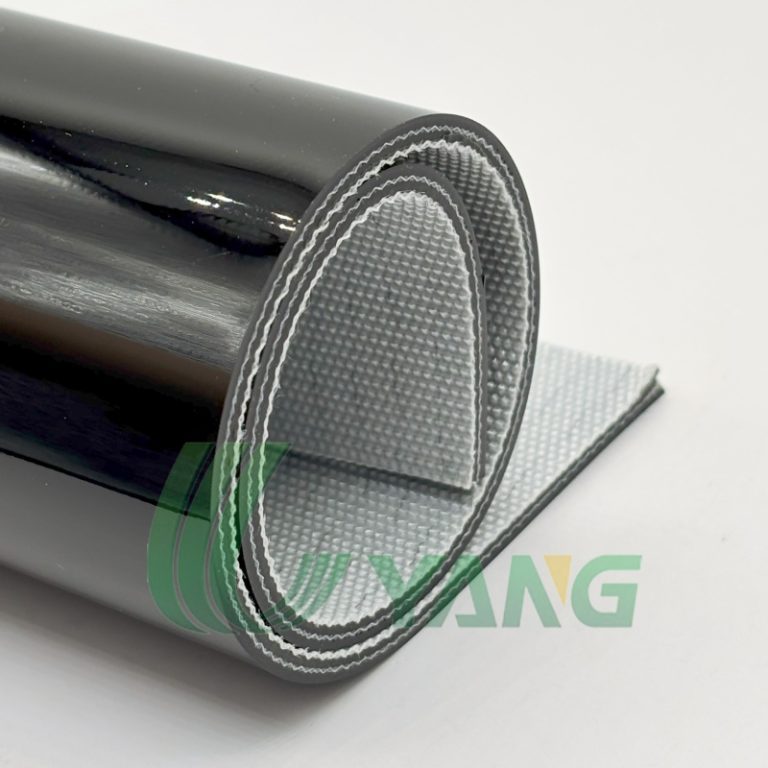

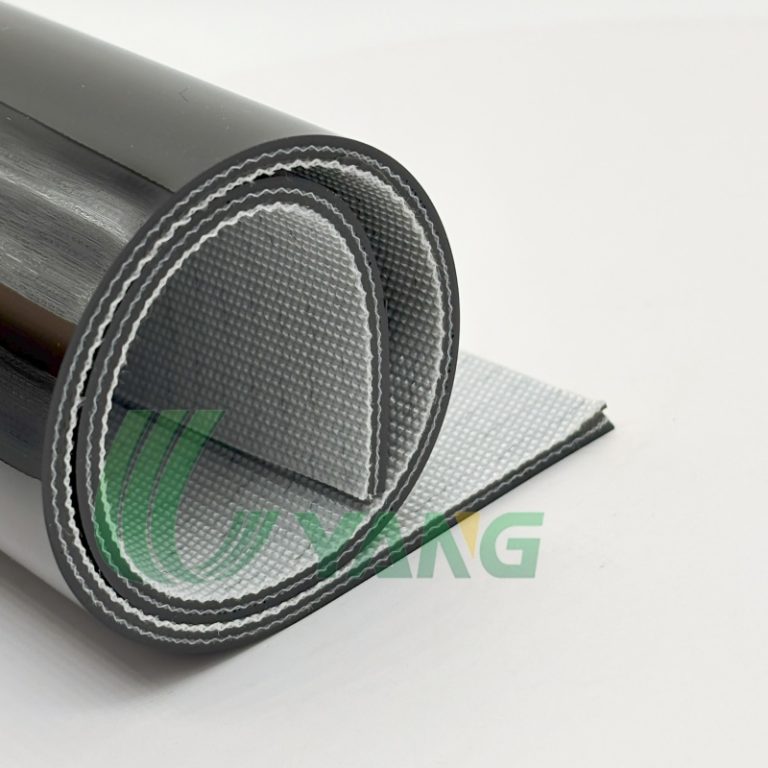

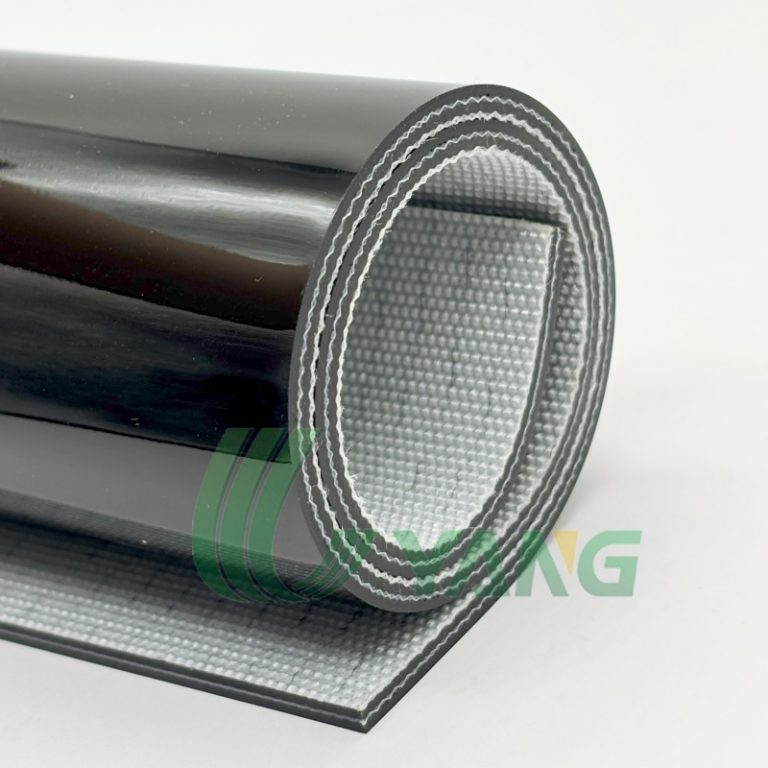

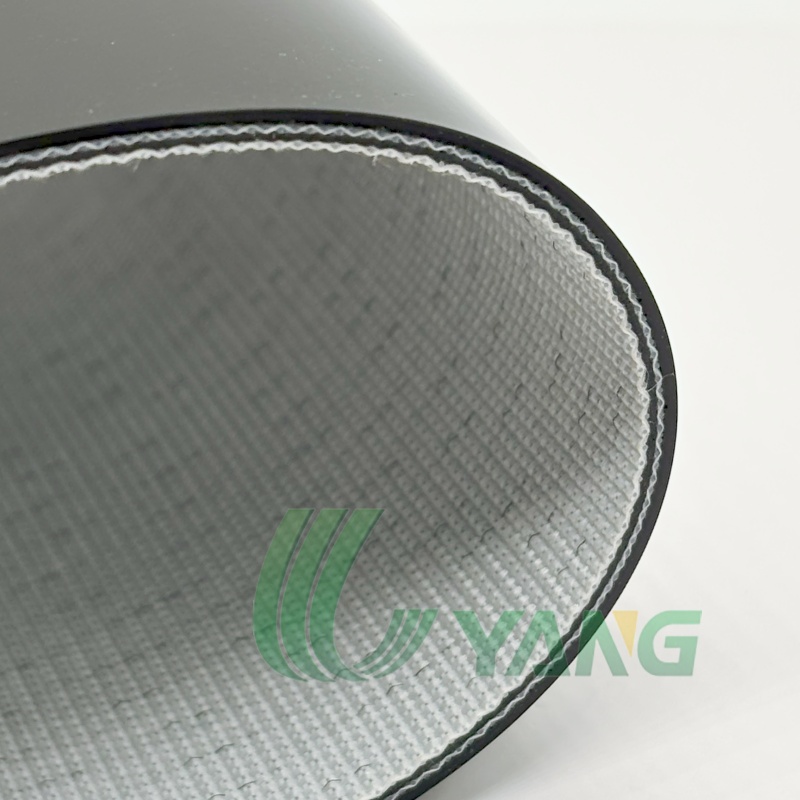

UYANG BELTING black glossy PVC conveyor belt falls under the category of light-duty conveyor belts. It features a smooth and flat surface, along with properties such as wear resistance, oil resistance, easy cleaning, and moisture resistance. Black PVC surface is widely used in applications that require a flat, aesthetically pleasing conveying surface, along with certain anti-contamination or friction-resistant performance.

UYANG BELTING black glossy PVC conveyor belt falls under the category of light-duty conveyor belts. It features a smooth and flat surface, along with properties such as wear resistance, oil resistance, easy cleaning, and moisture resistance. Black PVC surface is widely used in applications that require a flat, aesthetically pleasing conveying surface, along with certain anti-contamination or friction-resistant performance.

The black glossy PVC conveyor belt is primarily used in industrial, packaging, and logistics conveyor lines, rather than in the food industry.

For food-related applications, white or green food-grade PVC/PU conveyor belts that are oil-resistant, corrosion-resistant, and comply with food safety standards are generally preferred.

Farbe: Black

Oberfläche: Smooth (low coefficient of friction, suitable for rapid item transfer)

Material: PVC (wear-resistant, moisture-proof, anti-static options available)

Operating Environment: Room-temperature conveying; primarily for indoor use

Splicing Methods: Both thermal vulcanized splicing and mechanical fastener splicing are available

| Application& Industry | Typical Use | Recommended Thickness | Merkmale |

|---|---|---|---|

| Logistik und Sortierung | Express sorting, Airport Luggage, Warehouse handling | 2.0–3.0mm | Wear-resistant, smooth operation, easy to clean |

| Electronics & Manufacturing | Component handling, Appliance assembly lines | 1.5–2.0mm | Smooth surface, low friction, suitable for delicate parts |

| Tobacco Industry | Cigarettes, Cigarette box transportation | 2.0mm | Light-damage surface, keeps products clean and neat |

| Wood & Panel Industry | Furniture, wood boards, composite panels | 2.5–3.5mm | Good load capacity, flat surface |

| Gypsum / Building Materials | Gypsum board, a lightweight building material | 3.0–4.0mm | Wear-resistant, strong load capacity |

| General Packaging | Cartons, woven bags, finished product transport | 2.0–3.0mm | Stable operation, versatile use |

Zuverlässige Lieferpläne und Lagerunterstützung.

Wettbewerbspreise zur Maximierung des Gesamtwerts.

Verschiedene Optionen, um alle Marktsegmente gerecht zu werden.

Flexibler MOQ -Unterstützung mit allen Arten von Waren;

Personalisierte Logo -Anpassung an den Produkten

Bieten Sie den technischen Online -Support für alle Produktnutzungs- und Installationsprozesse

Schnelle erste Antwort auf alle Anfragen und Fragen

Stellen Sie Qualitätsbilder und Video zur Verfügung, um den Umsatzumsatz zu steigern

Effiziente Produktion und Schiff innerhalb von 15 Tagen am schnellsten.

Im Allgemeinen sind es 10-15 Tage, wenn die Hochsaison etwa 15 bis 20 Tage lang ist, erhält Safter die Kaution

1. Bestätigte Spezifikation: Dicke, Farbe, Lagen, Merkmale und Industrie;

2. Proben Senden: Wir senden Proben für Sie check.

3. Bestätigen Sie die Bestellung: Unterzeichnung des Verkaufsvertrags nach Bestätigung der Stichproben.

4. Kaution: 30% Einzahlung vor der Massenproduktion.

5. Produktion arrangiert: Wir werden die Produktion verarbeiten.

S.

7. Versand: Wir versenden die Waren an den Bestimmungshafen.

8. Bestätigen Sie die Belastungsrechnung {{url_placeholder_0}} Invoice {{url_placeholder_1}} list {{url_placeholder_2}} des Ursprungs;