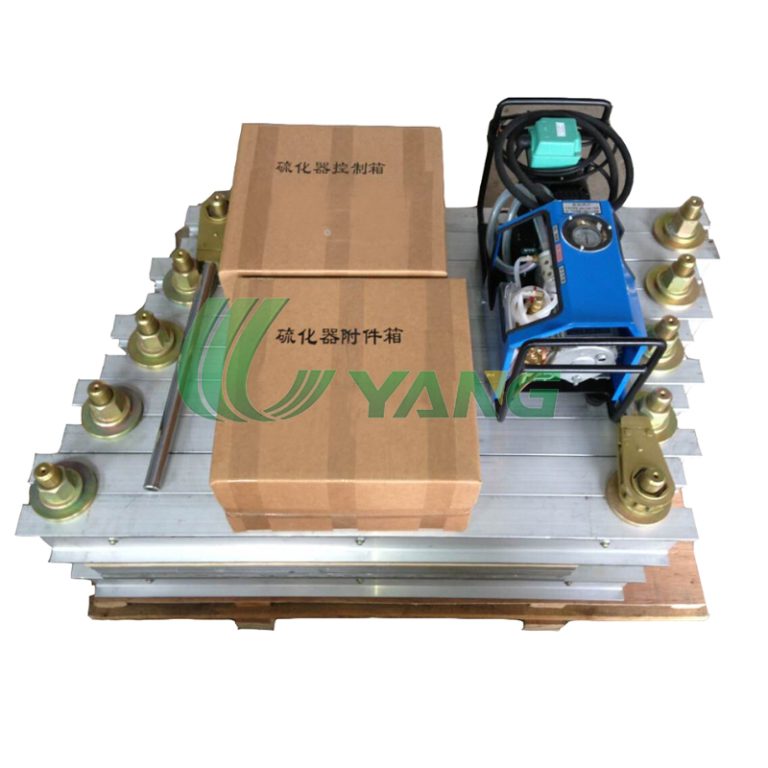

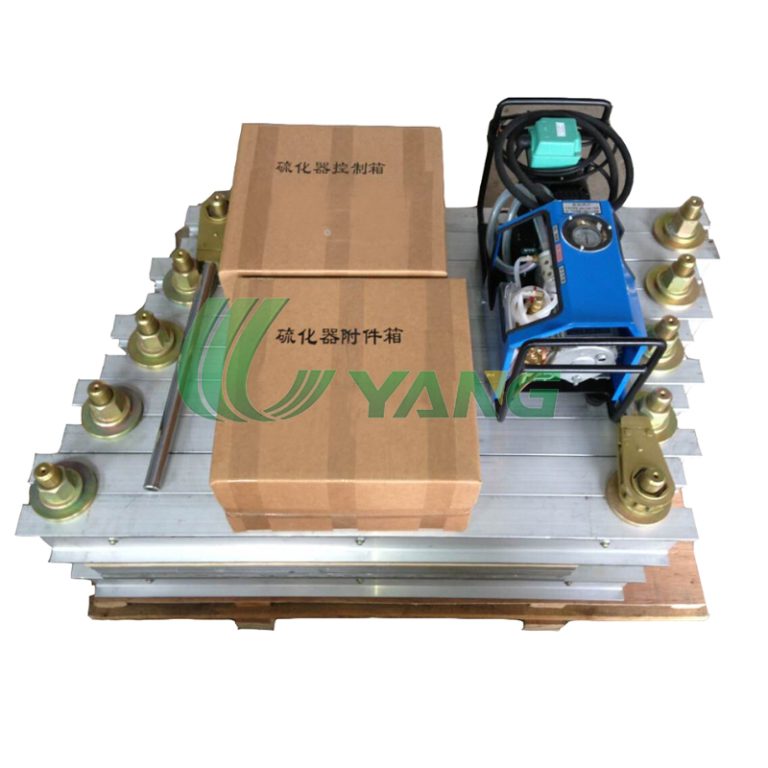

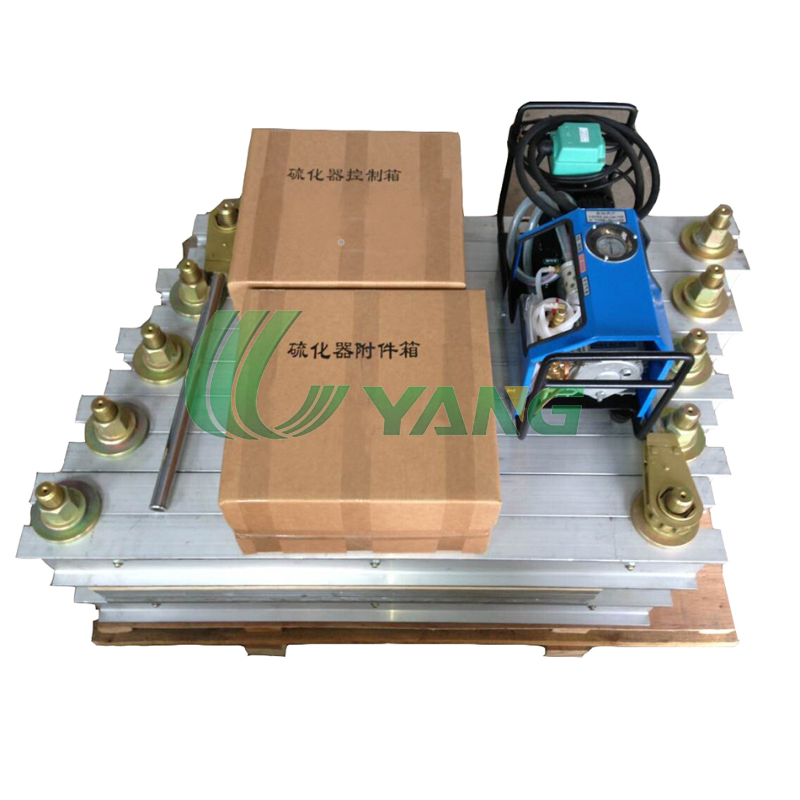

The UYCBV Series Conveyor Belt Vulcanizer is a portable and efficient splicing press designed for on-site vulcanization of rubber conveyor belts, including fabric, nylon, and steel cord types. Featuring uniform heating, stable pressure (0–1.5 MPa), and an integrated control cabinet, it ensures high-quality joints with minimal downtime. Widely used in mining, metallurgy, power plants, ports, and cement industries.

The UYCBV Series Conveyor Belt Vulcanizer is a portable and efficient splicing press designed for on-site vulcanization of rubber conveyor belts, including fabric, nylon, and steel cord types. Featuring uniform heating, stable pressure (0–1.5 MPa), and an integrated control cabinet, it ensures high-quality joints with minimal downtime. Widely used in mining, metallurgy, power plants, ports, and cement industries.

Portable Design – Compact and lightweight for easy transport and setup.

Uniform Heating – Ensures consistent vulcanization across the splice area.

Even Pressure – Stable pressure system (0–1.5 MPa) for strong, reliable joints.

Easy Operation – Plug-and-play control cabinet with integrated cables.

Wide Application – Suitable for various belt types and heavy industries.

Reliable On-Site Splicing for All Types of Rubber Belts

De UYCBV Conveyor Belt Vulcanizer is a versatile, field-ready vulcanizing press designed for high-efficiency splicing of rubber conveyor belts. Compact in size and lightweight for easy transport and installation, the UYCBV is ideal for on-site maintenance and emergency repairs.

Equipped with a uniform heating system and well-distributed pressure (0–1.5 MPa), this press ensures strong, durable belt joints. The integrated control cabinet and multi-core plug system allow for safe, stable, and efficient operation—with minimal maintenance.

Technical Parameters

Lightweight and portable for easy on-site setup

Uniform temperature and pressure for high joint quality

Automatic control cabinet with plug-and-play cable system

Suitable for canvas, nylon, steel cord, and heat/chemical-resistant belts

Widely used in mining, metallurgy, power plants, ports, cement, and more

Non-explosive and corrosion-safe environments only

Why It Matters:

The quality of a belt splice directly impacts conveyor performance and belt lifespan—especially for long-distance and high-strength systems. The UYCBV Vulcanizing Press is an essential tool for ensuring reliable, high-performance belt joints.

Pålidelige leveringsplaner og lagerstøtte.

Konkurrencedygtige priser for at maksimere den samlede værdi.

Diverse muligheder for at imødekomme alle markedssegmenter.

Fleksibel MOQ -support med alle typer varer;

Personaliseret logo -tilpasning på produkterne

Giv online teknisk support til alle produktforbrug og installationsprocesser

Hurtig første svar på al undersøgelse og spørgsmål

Giv kvalitetsbilleder, video for at forbedre salgsindtægterne

Effektiv produktion og skib inden for 15 dage på det hurtigste.

Generelt er det 10-15 dage, hvis højsæsonen, vil det være ca. 15-20 dages bunker, der modtager depositum

1. bekræftet specifikation: tykkelse, farve, lag, karakteristisk og industri;

2. Prøver Sending: Vi sender prøver til dig check.eller du sender os prøver, hvis tilpasset bælte.

3. Bekræft ordre: Signing af salgskontrakt efter prøver bekræftet.

4. depositum: 30% depositum før masseproduktion.

5. Produktion arrangeret: Vi behandler produktionen.

6. Resterende betaling: Efter inspektion, saldo før afsendelse.

7. Forsendelse: Vi sender varerne til destinationsporten.

8. Bekræft Bill of Loading {{url_placeholder_0}} faktura {{url_placeholder_1}} Liste {{url_placeholder_2}} af oprindelse;