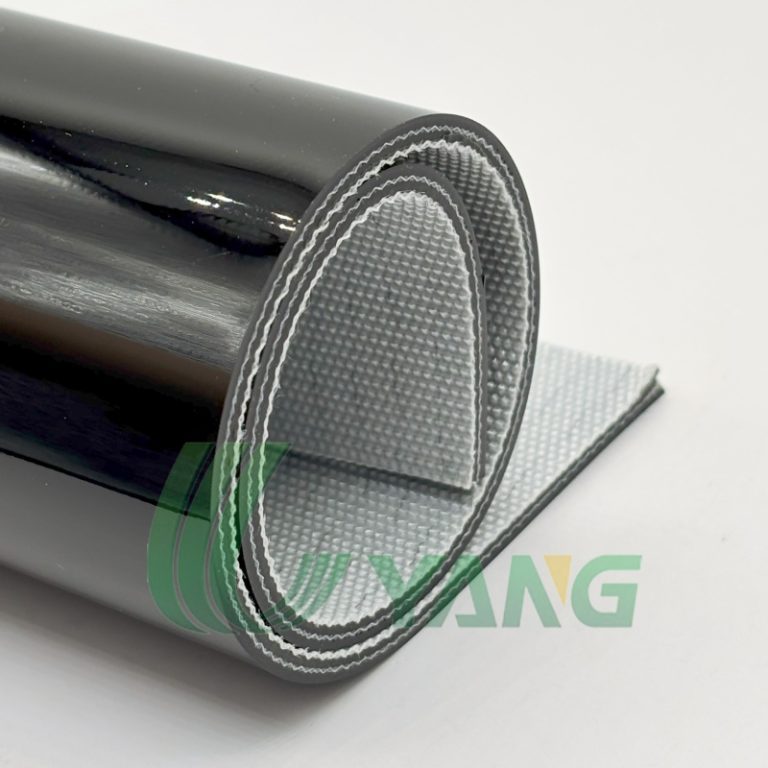

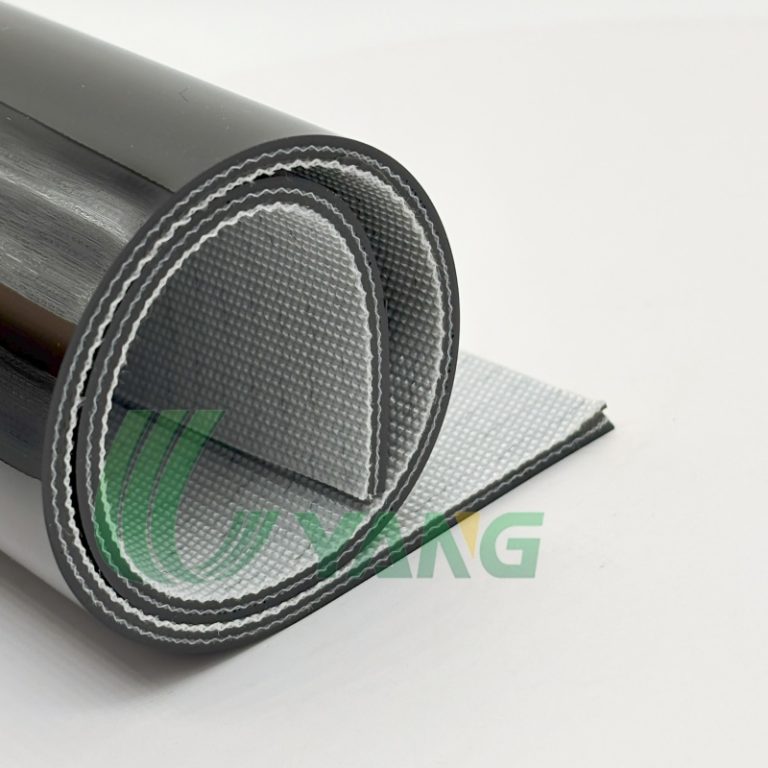

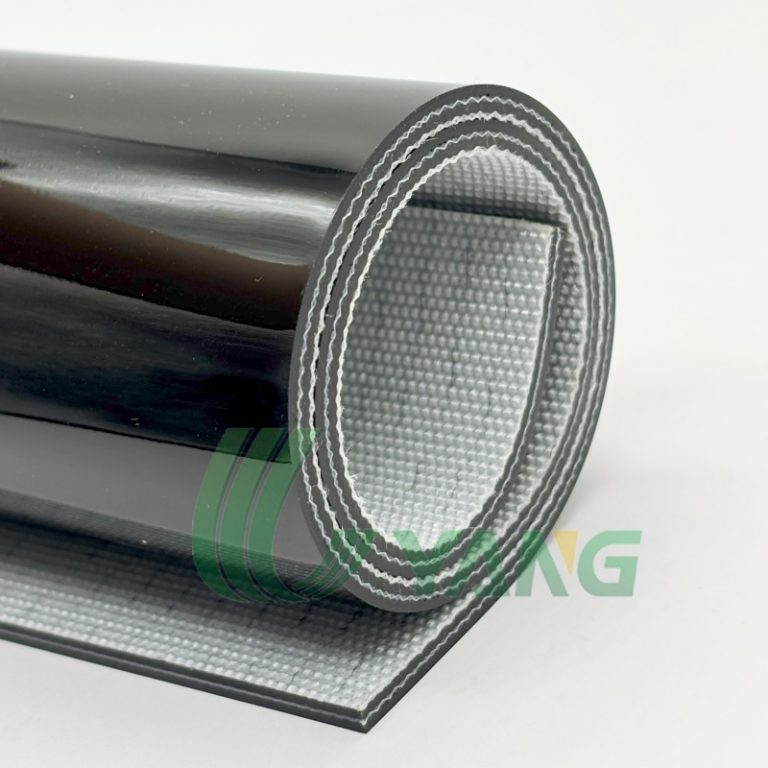

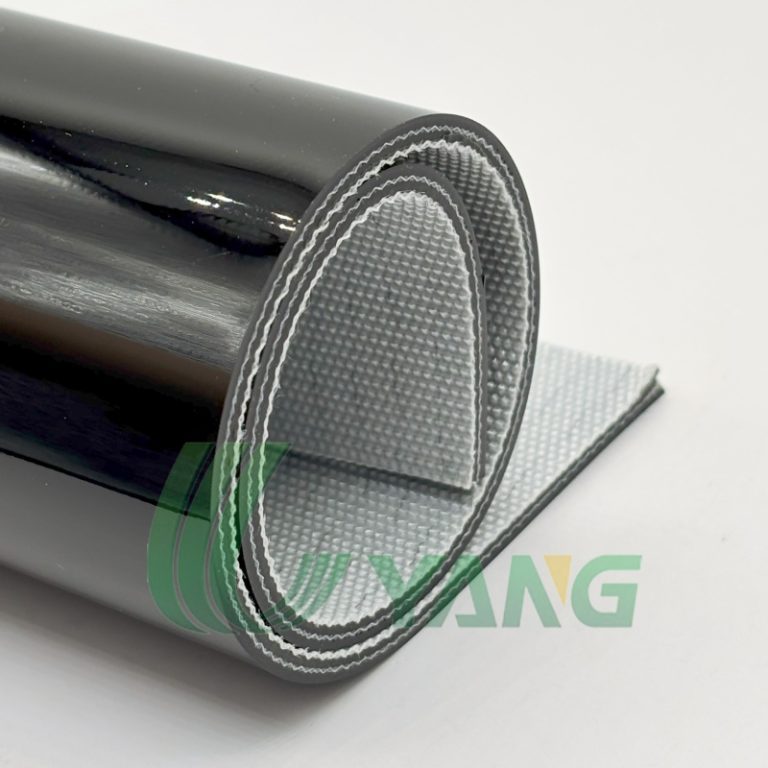

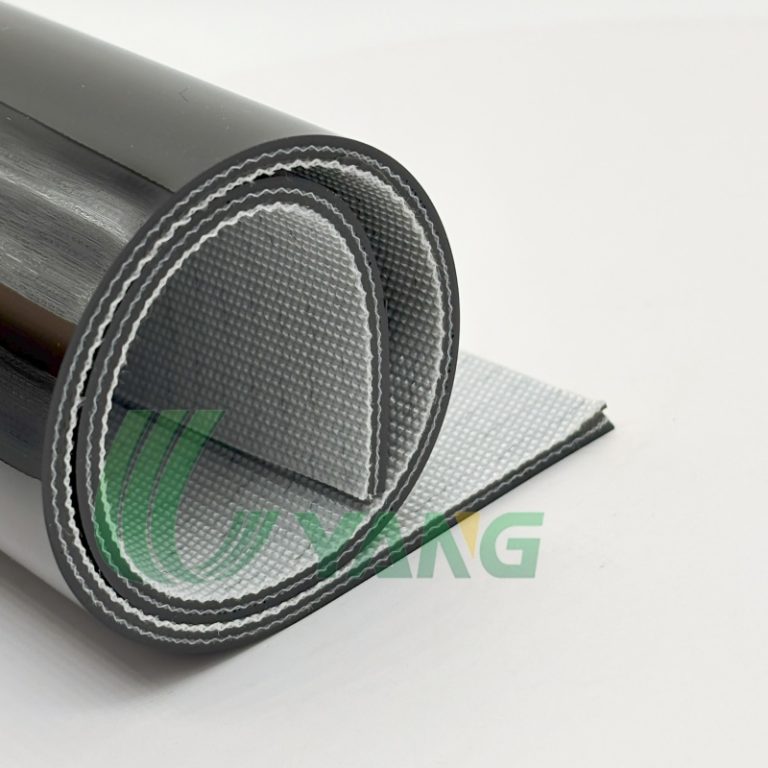

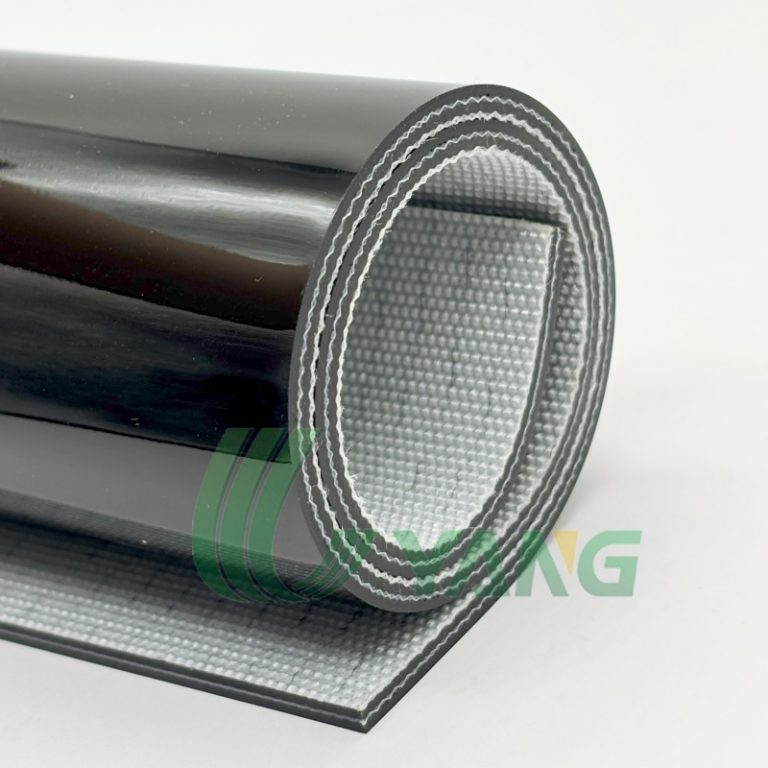

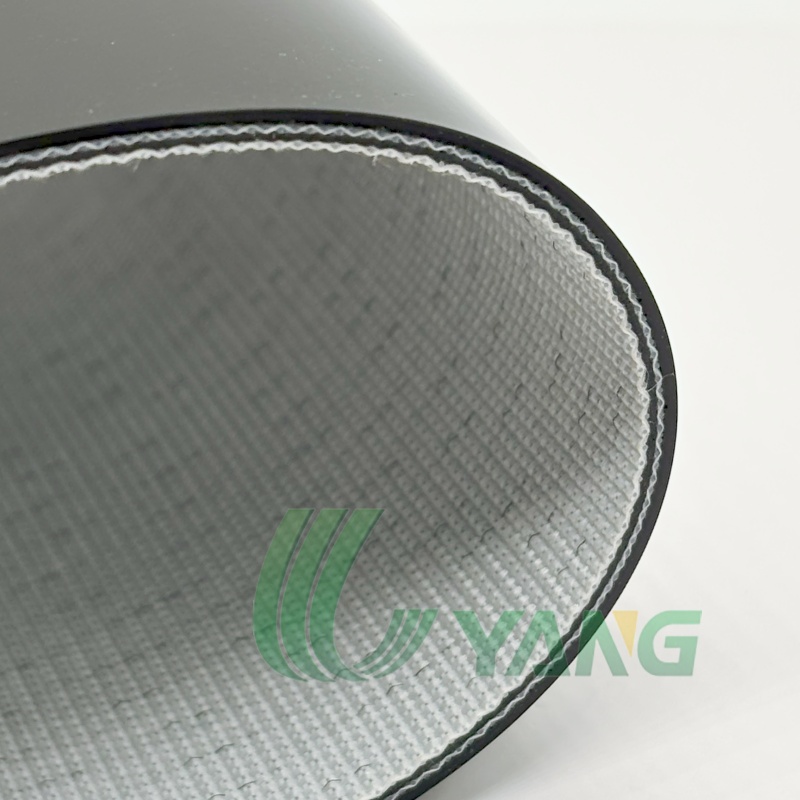

UYANG BELTING black glossy PVC conveyor belt falls under the category of light-duty conveyor belts. It features a smooth and flat surface, along with properties such as wear resistance, oil resistance, easy cleaning, and moisture resistance. Black PVC surface is widely used in applications that require a flat, aesthetically pleasing conveying surface, along with certain anti-contamination or friction-resistant performance.

UYANG BELTING black glossy PVC conveyor belt falls under the category of light-duty conveyor belts. It features a smooth and flat surface, along with properties such as wear resistance, oil resistance, easy cleaning, and moisture resistance. Black PVC surface is widely used in applications that require a flat, aesthetically pleasing conveying surface, along with certain anti-contamination or friction-resistant performance.

The black glossy PVC conveyor belt is primarily used in industrial, packaging, and logistics conveyor lines, rather than in the food industry.

For food-related applications, white or green food-grade PVC/PU conveyor belts that are oil-resistant, corrosion-resistant, and comply with food safety standards are generally preferred.

Farve: Black

Overflade: Smooth (low coefficient of friction, suitable for rapid item transfer)

Materiale: PVC (wear-resistant, moisture-proof, anti-static options available)

Operating Environment: Room-temperature conveying; primarily for indoor use

Splicing Methods: Both thermal vulcanized splicing and mechanical fastener splicing are available

| Application& Industry | Typical Use | Recommended Thickness | Funktioner |

|---|---|---|---|

| Logistik og sortering | Express sorting, Airport Luggage, Warehouse handling | 2.0–3.0mm | Wear-resistant, smooth operation, easy to clean |

| Electronics & Manufacturing | Component handling, Appliance assembly lines | 1.5–2.0mm | Smooth surface, low friction, suitable for delicate parts |

| Tobacco Industry | Cigarettes, Cigarette box transportation | 2.0mm | Light-damage surface, keeps products clean and neat |

| Wood & Panel Industry | Furniture, wood boards, composite panels | 2.5–3.5mm | Good load capacity, flat surface |

| Gypsum / Building Materials | Gypsum board, a lightweight building material | 3.0–4.0mm | Wear-resistant, strong load capacity |

| General Packaging | Cartons, woven bags, finished product transport | 2.0–3.0mm | Stable operation, versatile use |

Pålidelige leveringsplaner og lagerstøtte.

Konkurrencedygtige priser for at maksimere den samlede værdi.

Diverse muligheder for at imødekomme alle markedssegmenter.

Fleksibel MOQ -support med alle typer varer;

Personaliseret logo -tilpasning på produkterne

Giv online teknisk support til alle produktforbrug og installationsprocesser

Hurtig første svar på al undersøgelse og spørgsmål

Giv kvalitetsbilleder, video for at forbedre salgsindtægterne

Effektiv produktion og skib inden for 15 dage på det hurtigste.

Generelt er det 10-15 dage, hvis højsæsonen, vil det være ca. 15-20 dages bunker, der modtager depositum

1. bekræftet specifikation: tykkelse, farve, lag, karakteristisk og industri;

2. Prøver Sending: Vi sender prøver til dig check.eller du sender os prøver, hvis tilpasset bælte.

3. Bekræft ordre: Signing af salgskontrakt efter prøver bekræftet.

4. depositum: 30% depositum før masseproduktion.

5. Produktion arrangeret: Vi behandler produktionen.

6. Resterende betaling: Efter inspektion, saldo før afsendelse.

7. Forsendelse: Vi sender varerne til destinationsporten.

8. Bekræft Bill of Loading {{url_placeholder_0}} faktura {{url_placeholder_1}} Liste {{url_placeholder_2}} af oprindelse;