UYANG’s reinforced V-belts feature high-strength aramid fiber cores that minimize stretching (<0.3% elongation) and maintain stable power transmission. The advanced reinforcement reduces installation tension by 40% while supporting heavy loads, ensuring reliable performance in demanding industrial applications.

UYANG’s reinforced V-belts feature high-strength aramid fiber cores that minimize stretching (<0.3% elongation) and maintain stable power transmission. The advanced reinforcement reduces installation tension by 40% while supporting heavy loads, ensuring reliable performance in demanding industrial applications.

Nøglefunktioner:

50% higher load capacity

3-5x extended service life

Superior heat resistance (-40°C to +120°C) and abrasion

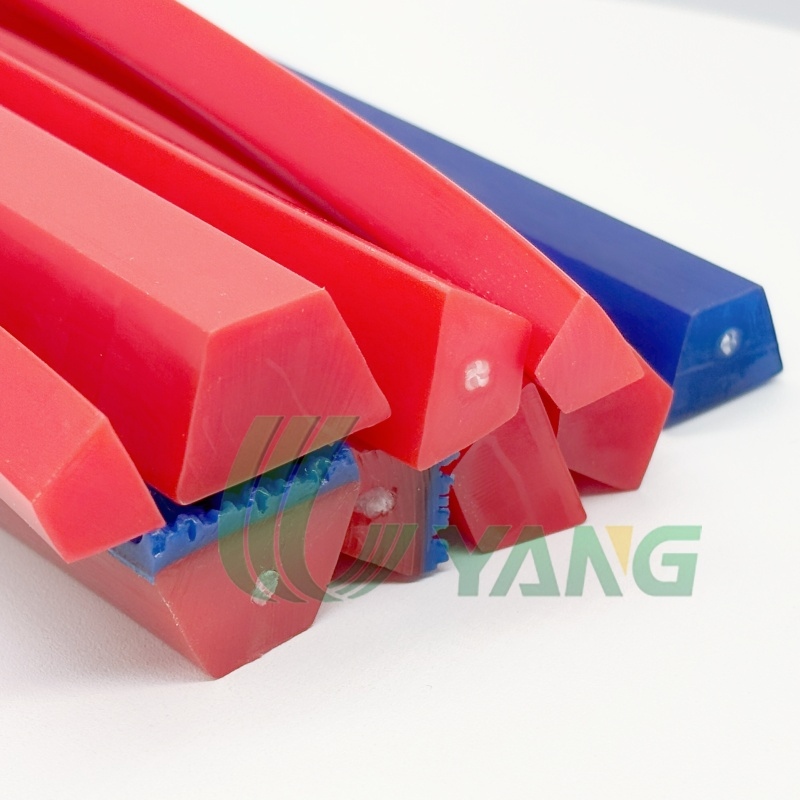

Available in food-grade, oil-resistant, and anti-static variants for specialized applications.

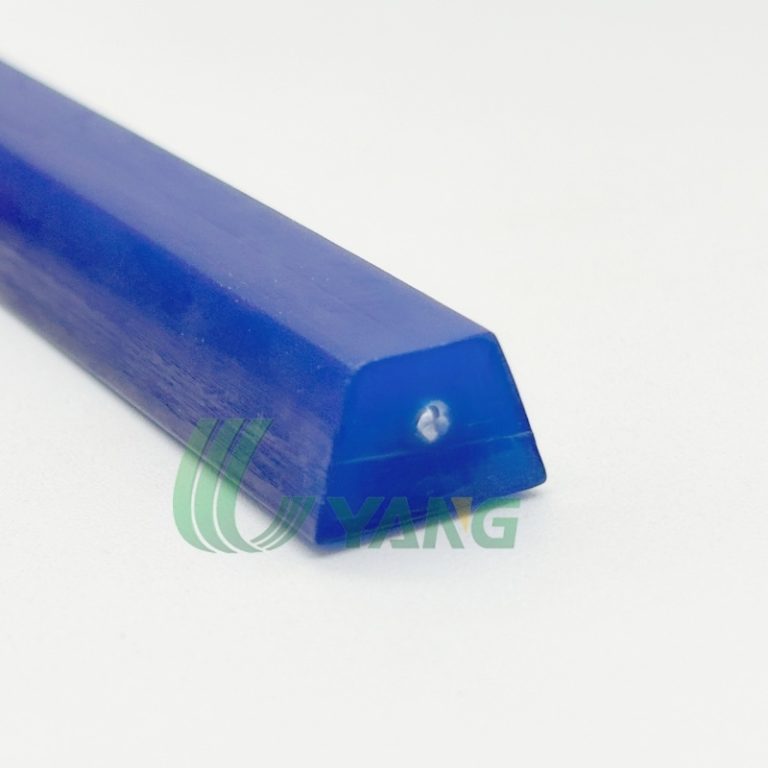

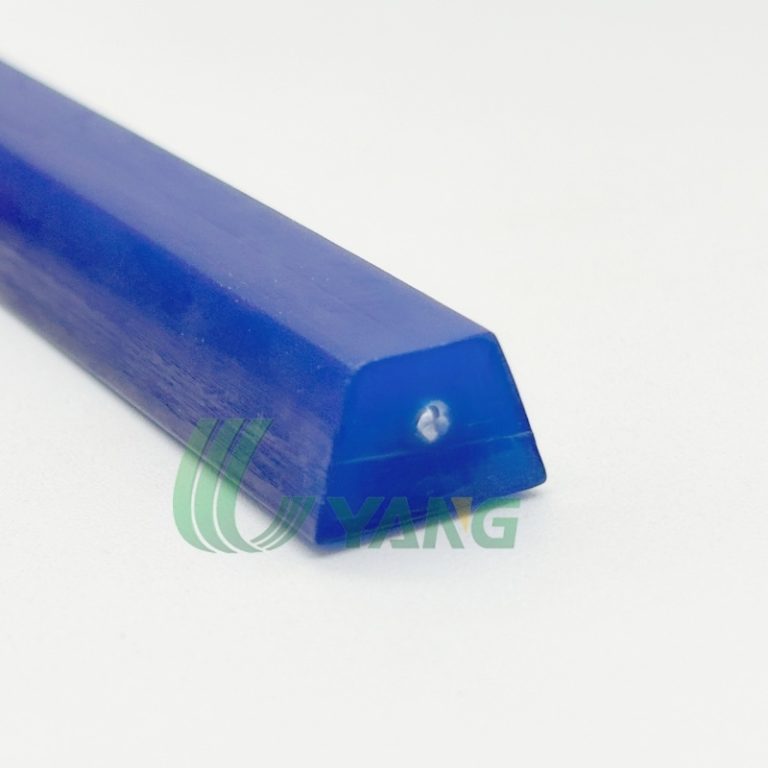

Product Construction with Core Reinforcement Layer:

Military-grade aramid fibers (Kevlar type) as a tensile carrier

Special weaving process achieves 2000N/mm² tensile strength

Innovative double-helix winding structure eliminates operational torque

Performance Advantages:

✓ Ultra-low stretch: Operational elongation <0.3%, exceeding industry standards

✓ Extended lifespan: 3- 5x longer service life than conventional V-belts

✓ Heavy-duty capacity: 50% higher load rating than standard belts

✓ Precision transmission: Over 98% efficiency guaranteed

Tekniske specifikationer:

Temperature range: -40℃ to +120℃ (special models)

Minimum pulley diameter: 60% of standard requirements

Fatigue resistance: Passed 2 million bending cycles

Special Application Designs:

• Food-grade: White TPU coating + detectable metal core

• Anti-static: Carbon fiber composite core (surface resistance 10⁶Ω)

• Oil-resistant: Special PU compound + anti-permeation layer

• Mining version: Flame-retardant coating + steel detection core

Installation Benefits:

▶ 40% reduced pre-tension for easier installation

▶ Unique wear indicator line for visual monitoring

▶ Sectional replacement capability cuts maintenance costs by 60%

Technical Data:

| Dimensions | Cross section | Approx. weight | Standard roll | Recommended min. pulley ∅ ⌀ | Fmax/belt (standard) | Fmax/belt (overlap) |

|---|---|---|---|---|---|---|

| mm | cm2 | kg/100m | m | mm | kg | kg |

| 8×5 (M) | 0,32 | 4 | 30 | 50 | 10,3 | 21,6 |

| 10×6 (Z) | 0,48 | 6.0 | 30 | 60 | 15,4 | 32,4 |

| 13×8 (A) | 0,82 | 10 | 30 | 85 | 25,9 | 54,5 |

| 13×8 (A) | 0,82 | 10 | 50 | 85 | 25,9 | 54,5 |

| 17×11 (B) | 1,46 | 18 | 30 | 110 | 46,9 | 98,6 |

| 17×11 (B) | 1,46 | 18 | 100 | 110 | 46,9 | 98,6 |

| 22×14 (C) | 2,4 | 29 | 30 | 150 | 77 | 150 |

| 32×20 (D) | 5 | 62 | 30 | 220 | 154 | n/a |

Typiske applikationer:

Heavy industry: Mining equipment, steel plant conveyors

Automotive: Engine assembly lines, test benches

Food processing: High-temperature sterilization lines

Logistics: High-speed sorting systems

Our Services:

• Free technical selection support

• 48-hour sample delivery

• On-site installation guidance

• Customized solutions

(Detailed test reports and industry certifications available upon request)

Pålidelige leveringsplaner og lagerstøtte.

Konkurrencedygtige priser for at maksimere den samlede værdi.

Diverse muligheder for at imødekomme alle markedssegmenter.

Fleksibel MOQ -support med alle typer varer;

Personaliseret logo -tilpasning på produkterne

Giv online teknisk support til alle produktforbrug og installationsprocesser

Hurtig første svar på al undersøgelse og spørgsmål

Giv kvalitetsbilleder, video for at forbedre salgsindtægterne

Effektiv produktion og skib inden for 15 dage på det hurtigste.

Generelt er det 10-15 dage, hvis højsæsonen, vil det være ca. 15-20 dages bunker, der modtager depositum

1. bekræftet specifikation: tykkelse, farve, lag, karakteristisk og industri;

2. Prøver Sending: Vi sender prøver til dig check.eller du sender os prøver, hvis tilpasset bælte.

3. Bekræft ordre: Signing af salgskontrakt efter prøver bekræftet.

4. depositum: 30% depositum før masseproduktion.

5. Produktion arrangeret: Vi behandler produktionen.

6. Resterende betaling: Efter inspektion, saldo før afsendelse.

7. Forsendelse: Vi sender varerne til destinationsporten.

8. Bekræft Bill of Loading {{url_placeholder_0}} faktura {{url_placeholder_1}} Liste {{url_placeholder_2}} af oprindelse;