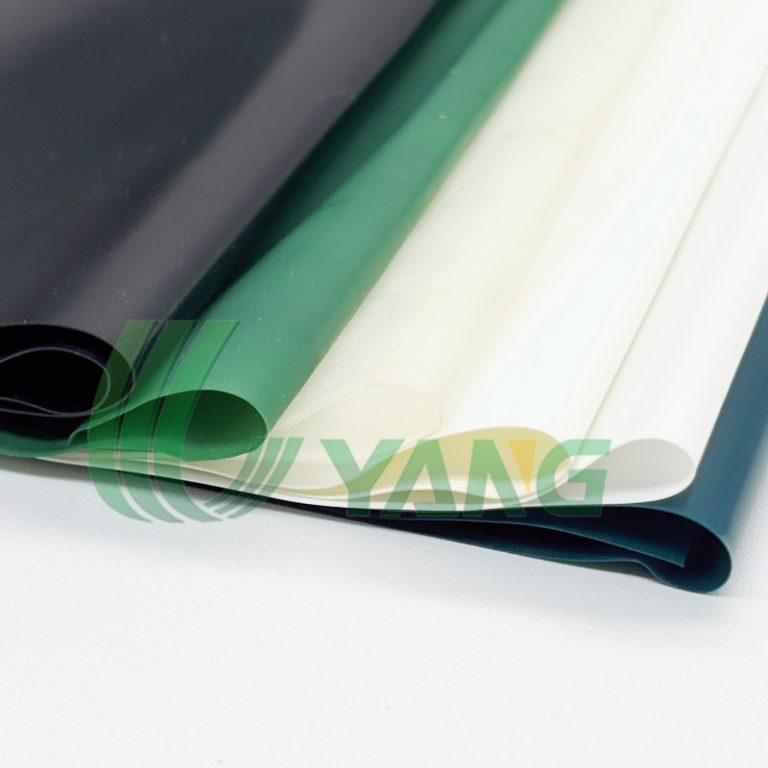

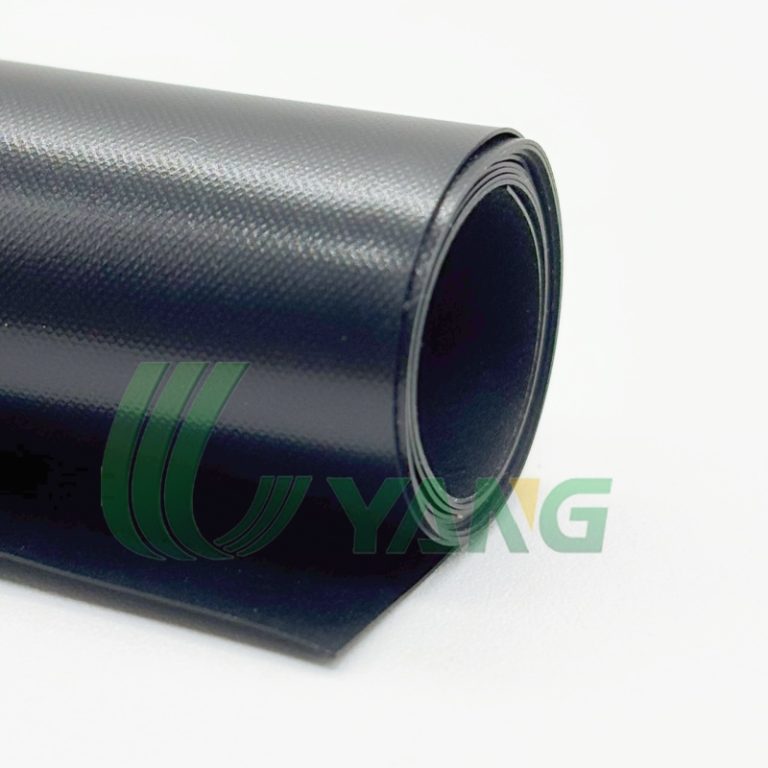

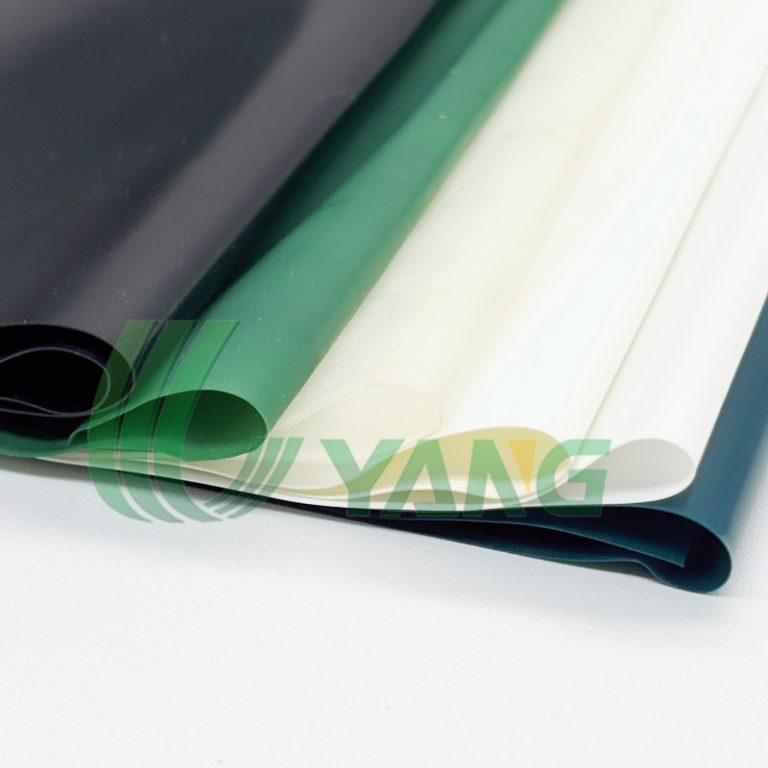

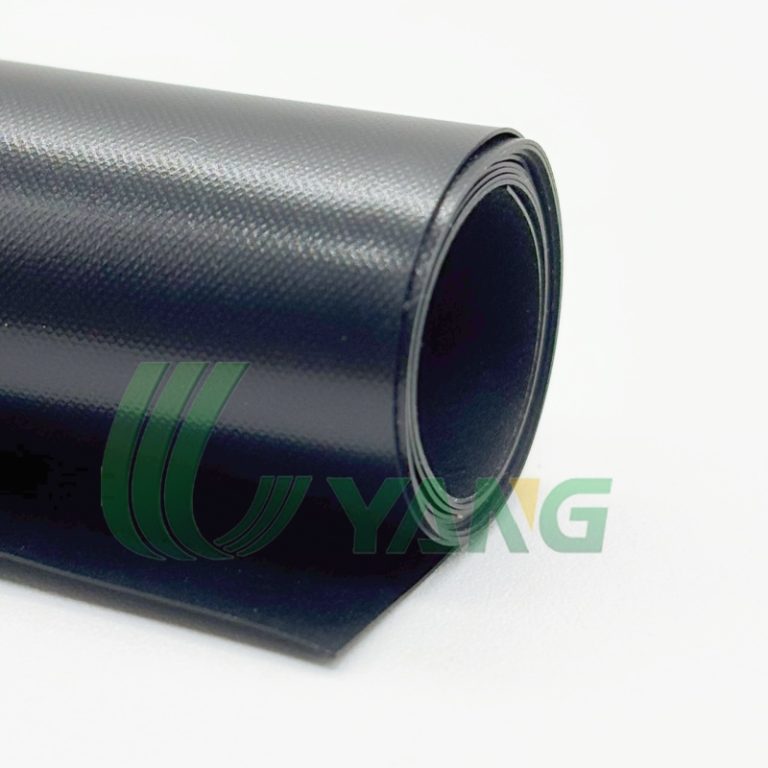

UYANG BELTING PVC/PU splice film is engineered for reliable splicing of PVC and PU conveyor belts — producing smooth, low-profile joints that maintain belt strength and tracking. Available in multiple colors for easy identification and seamless aesthetics.

UYANG BELTING PVC/PU splice film is engineered for reliable splicing of PVC and PU conveyor belts — producing smooth, low-profile joints that maintain belt strength and tracking. Available in multiple colors for easy identification and seamless aesthetics.

Key Advantages:

Strong & Durable – ensures reliable, long-lasting belt splicing.

Easy to Use – smooth welding for clean, low-profile joints.

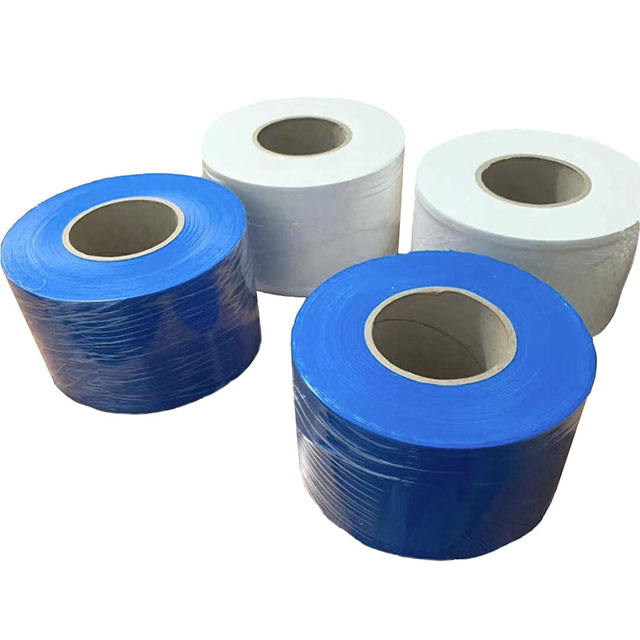

Color Options – blue, black, green, and white for coding and visual management.

Key benefits

Produces clean, low-profile splices that reduce product catch points and contamination.

Color options (blue/black/green/white) help with line coding, hygiene zones and visual inspection.

Good wear and abrasion resistance to match belt performance.

Easy to weld or fuse with standard splicing methods (hot air, hot-press/vulcanization, or compatible welding processes).

Improves splice consistency and durability compared with untreated joints.

Custom widths and thicknesses available to suit different belt types and joint requirements.

Food-grade formulations available on request for hygiene-sensitive lines.

Typical specifications (examples — customizable)

Material: PVC or PU splice film (select by application)

Thickness: 0.2 mm — 1.0 mm (common sizes; custom on request)

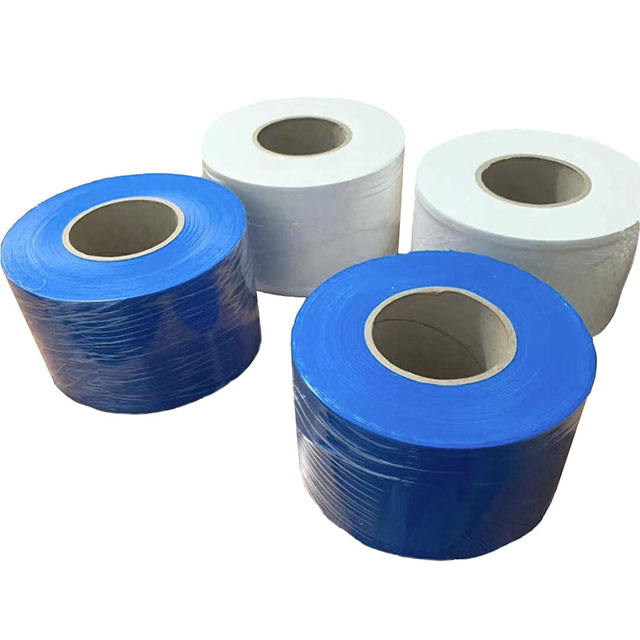

Size: 100mm*100M/Roll;

Colors: Blue, Black, Green, White

Temperature resistance: suitable for normal washdown and processing environments (spec depends on selected material grade)

Packaging: rolls or pre-cut sheets/strips for on-site splicing

Applications

Splicing of PVC/PU conveyor belts in food processing, packaging, logistics and light industry.

Quick field repairs and factory splices for production lines.

Color-coded conveyor zones (e.g., raw vs. cooked, allergen control, sanitation areas).

Installation & usage notes

Clean and prepare belt ends—remove debris and ensure even edges.

Position splice film between belt ends; align carefully for tracking.

Use the recommended splicing method for your belt material (hot-press/vulcanization, hot-air welding, or compatible fusion technique).

Allow joint to cool/cure fully before loading.

Inspect splice for smoothness and alignment; trim or reseal edges if needed.

Why choose our splice film

Color-coded, durable and easy-to-use — our PVC/PU splice films give you reliable, professional joints that keep conveyors running cleaner and smoother while supporting quick repairs and consistent manufacturing standards.

Reliable delivery schedules and warehousing support.

Competitive pricing to maximize overall value.

Diverse options to cater to all market segments.

Flexible MOQ Support with all types of goods;

Personalized logo customization on the products

Provide online technical support for all product usage and installation processes

Quick first response to all inquiry and questions

Provide quality images, Video to enhance sales revenue

Efficient production and ship within 15 days at the fastest.

Generally it is 10-15 days, if peak season, it will be about 15-20 day safter receiving the deposit

1। নিশ্চিত করা স্পেসিফিকেশন: বেধ, রঙ, প্লিজ, বৈশিষ্ট্যযুক্ত এবং শিল্প;

2। নমুনা প্রেরণ: আমরা আপনার জন্য নমুনাগুলি প্রেরণ করি C

3। অর্ডার নিশ্চিত করুন: নমুনাগুলি নিশ্চিত হওয়ার পরে বিক্রয় চুক্তিতে স্বাক্ষর করা।

4। আমানত: ভর উত্পাদনের আগে 30% আমানত।

5। উত্পাদন সাজানো: আমরা উত্পাদন প্রক্রিয়া করব।

।। বাকি অর্থ প্রদান: পরিদর্শন করার পরে, চালানের আগে ভারসাম্য।

7। শিপিং: আমরা পণ্যগুলি গন্তব্য বন্দরে প্রেরণ করব।

8। লোডিংয়ের বিলটি নিশ্চিত করুন {{url_placeholder_0}} চালান {{url_placeholder_1}} তালিকা {{url_placeholder_2}}}}}}}}};;